www.industry-asia-pacific.com

23

'24

Written on Modified on

MITSUBISHI ELECTRIC RECEIVES ORDER FOR 84KV DRY AIR INSULATED SWITCHGEAR FROM ELECTRIC POWER COMPANY IN JAPAN

The order expands the company's lineup of greenhouse gas-free products, helping to achieve carbon neutrality.

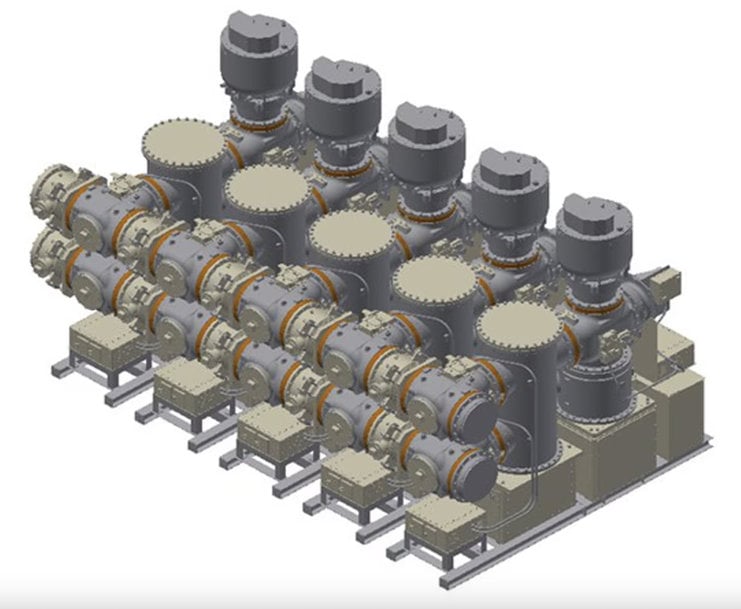

84kV dry air insulated switchgear

Mitsubishi Electric Corporation announced that it has received an order from Kansai Transmission and Distribution, Inc. (Osaka, Japan) for its 84kV dry air insulated switchgear, a new environmentally friendly, greenhouse gas-free product for use in gas-insulated switchgear (GIS) to be installed in substations. Mitsubishi Electric is the first company in Japan to develop GIS which does not utilize greenhouse gases, with two of the main components-vacuum interrupter (VI) and vacuum circuit breaker-developed in-house.

GIS and other types of switchgear are used to switch power routes and protect equipment from current spikes that may occur during system faults. Since delivering Japan's first 84kV GIS in 1968, Mitsubishi Electric has supplied switchgear for use in electric power grids all over the world, helping to provide stable electric power supplies for over half a century. However, current switchgear uses sulfur hexafluoride (SF6) gas, which has a global warming potential (GWP) approximately 24,300 times that of CO2. Although SF6 gas emissions from equipment have been minimized, the development of switchgear that does not use SF6 gas has been progressing in response to the recent demand for a reduction in environmental impact and the establishment of regulations to limit the use of SF6 gas.

The 84kV dry air insulated switchgear that Mitsubishi Electric has developed uses VI to interrupt current and dry air insulation as an alternative to SF6 gas. These have been in production since 1965, and have excellent insulation performance. Synthetic dry air, which has zero GWP, is used as insulation medium. This ensures high safety, helps to reduce environmental impact, and improves the efficiency of operation and maintenance. This first order for the new product recognizes its advanced technology and its reduced environmental impact. Delivery of the equipment is scheduled for March 2026.

Mitsubishi Electric Corporation announced that it has received an order from Kansai Transmission and Distribution, Inc. (Osaka, Japan) for its 84kV dry air insulated switchgear, a new environmentally friendly, greenhouse gas-free product for use in gas-insulated switchgear (GIS) to be installed in substations. Mitsubishi Electric is the first company in Japan to develop GIS which does not utilize greenhouse gases, with two of the main components-vacuum interrupter (VI) and vacuum circuit breaker-developed in-house.

GIS and other types of switchgear are used to switch power routes and protect equipment from current spikes that may occur during system faults. Since delivering Japan's first 84kV GIS in 1968, Mitsubishi Electric has supplied switchgear for use in electric power grids all over the world, helping to provide stable electric power supplies for over half a century. However, current switchgear uses sulfur hexafluoride (SF6) gas, which has a global warming potential (GWP) approximately 24,300 times that of CO2. Although SF6 gas emissions from equipment have been minimized, the development of switchgear that does not use SF6 gas has been progressing in response to the recent demand for a reduction in environmental impact and the establishment of regulations to limit the use of SF6 gas.

The 84kV dry air insulated switchgear that Mitsubishi Electric has developed uses VI to interrupt current and dry air insulation as an alternative to SF6 gas. These have been in production since 1965, and have excellent insulation performance. Synthetic dry air, which has zero GWP, is used as insulation medium. This ensures high safety, helps to reduce environmental impact, and improves the efficiency of operation and maintenance. This first order for the new product recognizes its advanced technology and its reduced environmental impact. Delivery of the equipment is scheduled for March 2026.

www.mitsubishielectric.com