www.industry-asia-pacific.com

18

'15

Written on Modified on

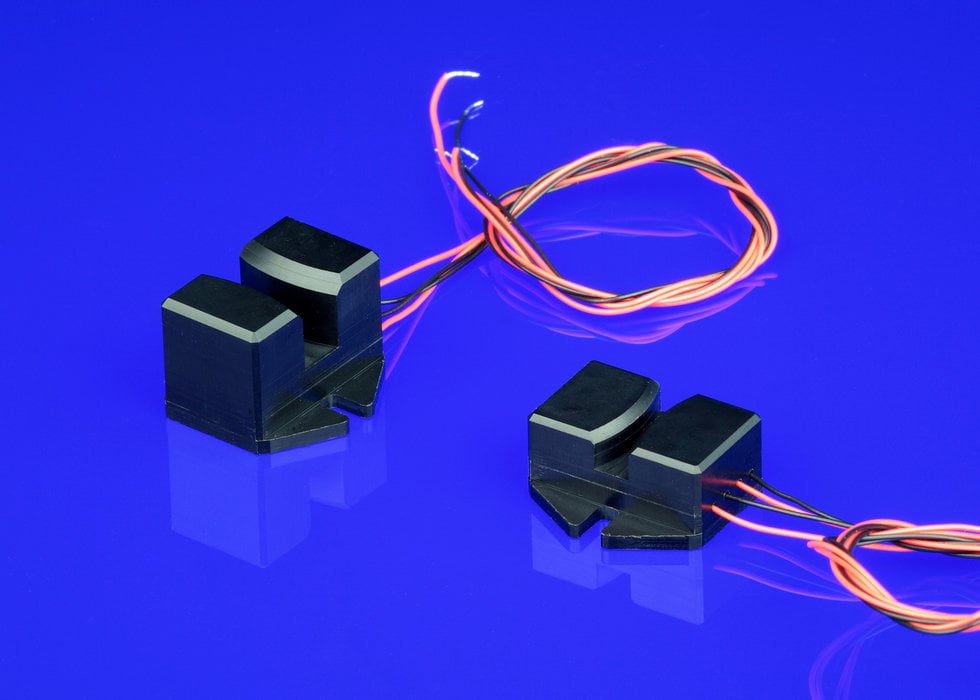

MORGAN EXTENDS AIR-IN-LINE SENSOR CAPABILITIES

Offering highly reliable detection of air bubbles in medical dosing applications, the acclaimed range of air-in-line (AIL) sensors from Morgan Advanced Materials has been extended to provide two new capabilities in line with demand from medical original equipment manufacturers (OEMs).

Already offering AIL sensors for 6.35mm and 4mm tubing, the second new addition to Morgan’s range is a sensor specifically designed for 2.5mm diameter tubing. Allowing detection of air bubbles in much narrower tubes, the new sensor is ideal for use in compact medical equipment where space inside may be limited.

Oliver Ridd of Morgan Advanced Materials commented: “Morgan’s ultrasonic AIL sensors are used in a wide range of medical equipment such as haemodialysis machines, cardio-pulmonary bypass systems and infusion pumps. They help prevent air bubbles from entering a patient’s bloodstream which could have potentially fatal consequences. With our dedicated design and development team we are continually expanding and improving the capabilities of our sensors. Our speciality lies in designing bespoke products dependant on customer requirements and these two new capabilities serve to broaden the already extensive range of applications for AIL sensors and further increase the scope for customised solutions.”

For more information, please visit http://www.morganelectroceramics.com/airsensors.