www.industry-asia-pacific.com

26

'18

Written on Modified on

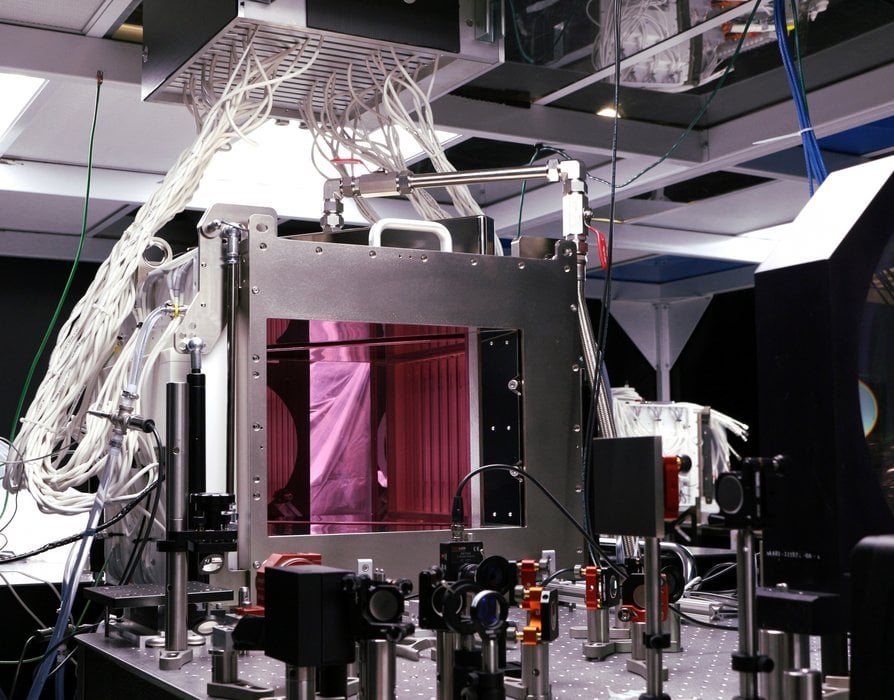

Morgan Advanced Materials develops ceramic reflector for world’s most powerful laser system

The ceramic reflector for the world’s most powerful laser system has been developed and manufactured by Morgan Advanced Material’s Technical Ceramics business in the UK, for use in a ground-breaking new 10-petawatt (10x1015W) laser system to be installed in the Czech Republic. The laser will achieve output pulses with energies in excess of 1.5kJ that are under 150 femtoseconds in duration, with a once a minute repetition rate. The power output during the ultra-short pulse of the laser will be approximately 100 times greater than the Global power usage.

In mainstream flash lamp laser systems, designers typically choose between ceramic or gold coated metal reflectors. In addition to being more economical than gold coated parts for the size of reflector required, Morgan’s engineered ceramic reflector has been proven to provide an improved reflectivity performance, reflecting almost 100% of light between 500-2000nm wavelengths. This high reflectivity prevents the ceramic from absorbing the lamp energy and heating up.

The special material composition of Morgan’s ceramic reflector has been developed to offer improved laser gain over other materials, ensuring that the user received maximum energy output and efficiency from the laser. Maximising the gain from each amplifier that contains the ceramic components minimises the number of amplifier modules required and therefore the size and overall cost of the system. Another major benefit of National Energetics’ laser is created by their liquid cooling system which has enabled quicker cycling of the laser, meaning users are able to pulse the laser once per minute instead of the once per hour that existing systems allow. This dramatically compresses the amount of time needed to conduct experiments and collect data, maximising throughput in the facility.

Oliver Ridd, from the Technical Ceramics business of Morgan Advanced Materials commented: “We are proud to have developed one of the largest ceramic reflectors ever for this project. Using ceramic for this project has proved to be an effective move, and we are now looking to engage with other commercial and industrial projects of a similar nature where our ceramic material will provide performance benefits. We are delighted to have worked with National Energetics to provide an integral component for this extraordinary cutting edge laser.”

The laser system, once installed, will become an invaluable tool in furthering the understanding of astrophysical phenomena and investigating new physics at previously unattainable light intensities. It will be housed in the government funded facility to aid scientific research for global research projects. National Energetics’ laser system is currently on track for delivery to the Czech Republic in 2018.

For further information, please visit: http://www.morgantechnicalceramics.com/LaserReflector