www.industry-asia-pacific.com

12

'23

Written on Modified on

LASER TECHNOLOGY FOR ENERGY-EFFICIENT PRODUCTION OF BATTERY CELLS

Researchers at the Fraunhofer Institute for Laser Technology ILT in Aachen have developed innovative laser-based technologies for producing lithium-ion batteries — which, in comparison with those produced conventionally, can be charged more quickly and have a longer service lifetime.

Whether they are used in stationary energy storage systems or in electric cars, buses, bikes and scooters, batteries will play a central role in the mobility of the future. This is why researchers around the world are working on improving battery technology. Scientists at Fraunhofer ILT in Aachen have recently developed two laser-based manufacturing technologies that save energy in production while also making it possible to create battery cells with higher power density and a longer service life.

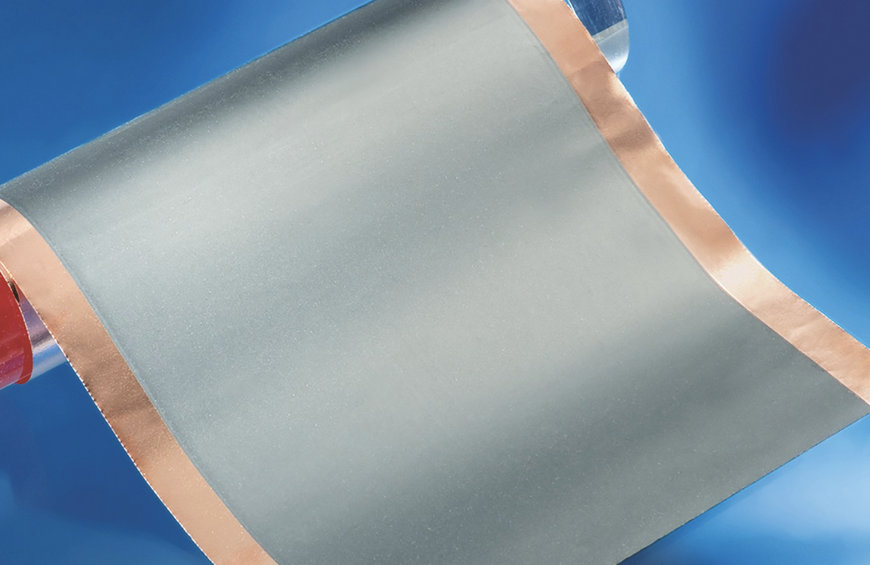

One of the key steps in the production of lithium-ion batteries is the manufacturing of electrodes using graphite. For these electrodes, a copper foil is coated with a graphite paste using the roll-to-roll process and then dried in a continuous furnace at 160 to 180 degrees Celsius. As well as consuming a large amount of energy, the gas-powered continuous furnaces, through which the copper foil is carried on a conveyor belt, take up a lot of space: They are between 60 and 100 meters long and dry up to 100 meters of foil per minute when operating on an industrial scale.

Efficient drying with diode lasers

The researchers at Fraunhofer ILT have now developed a system in which a diode laser carries out the drying process. The laser with a wavelength of 1 micrometer is combined with a special optical system that illuminate the electrode over a large area. The optics were specially designed for the drying system by Fraunhofer’s industry partner Laserline. Samuel Fink, group manager for Thin Film Processing at Fraunhofer ILT, explains the principle behind the process: “In contrast to the hot-air drying process, our diode laser projects a high-intensity beam onto the copper foil, which is coated with graphite paste. The jet-black graphite absorbs the energy. The resulting interaction causes the graphite particles to heat up and the liquid to evaporate.” The Fraunhofer technology provides a number of benefits: Compared to power-guzzling continuous furnaces, the diode laser is very energy-efficient, and the system emits very little heat to the environment. Furthermore, the laser drying system takes up much less space than conventional furnaces. “Drying with the diode laser will reduce the energy required by up to 50 percent and the space needed for a drying system on an industrial scale by at least 60 percent,” Fink predicts.

Modified 3D electrode structure for improved performance

In addition to these benefits, the team at Fraunhofer ILT has been able to improve the power density and service lifetime of the lithium-ion batteries. Once again laser technology is in the limelight: in this case, a high-power ultrashort pulse laser (USP) with 1 millijoule of pulse energy introduces a hole structure, referred to as channels, into the battery electrode. These channels serve as Li-ion highways for the ions — they significantly reduce the distance the ions have to travel and shorten the charging process. At the same time, this prevents defects from occurring, which in turn increases the number of potential charging cycles and ultimately extends the lifetime of the battery.

Both the laser-based process for producing the hole structures and the positive effect they have on the battery cell are well-known, in theory. What the Fraunhofer researchers have done is to transfer the principles from the laboratory to a scalable, industry-ready process that uses ultrashort pulse laser radiation in the femtosecond range to modify the electrodes. “The short interaction time of the laser pulses is sufficient to ablate the material, but also prevents the holes from melting, which means that the battery does not lose power,” explains Matthias Trenn, team leader for Surface Structuring at Fraunhofer ILT.

One of the challenges was working out how to use this process on larger areas in order to achieve the high throughput required for industrial production. The Fraunhofer team solved this problem by using a multi-beam arrangement for parallel process control. Four scanners, each with six beamlets, process the tape in parallel. They cover a width of 250 millimeters and process the graphite layer continuously. The multi-beam optics were developed and implemented in close collaboration with Pulsar Photonics GmbH, a Fraunhofer ILT spin-off founded in 2013.

The research conducted at Fraunhofer ILT demonstrates that laser technology can be used as a digital production process to improve the quality of battery cells and significantly increase sustainability during manufacturing. “The next step is to scale up the technology from the prototype to an industrial production line,” says Matthias Trenn.

People visiting the Fraunhofer booth (Hall 16, Booth A12) at the Hannover Messe 2023 (April 17 to 21) will be able to see a demonstration illustrating how the system is designed.

www.fraunhofer.com