www.industry-asia-pacific.com

19

'17

Written on Modified on

NORD DRIVESYSTEMS at CBST 2017 in China

The 8th China International Beverage Industry Exhibition on Science and Technology (CBST) will take place in Shanghai from 22 to 24 November 2017.

NORD DRIVESYSTEMS, one of the world's leading drive specialists, will be there again this year. The internationally operating company with head office in the north German city of Bargteheide and sites in China (HQ and motor production plant in Suzhou, assembly plant in Tianjin) will be at the renowned trade fair in the Shanghai New International Expo Centre (SNIEC) to present innovative technologies and products, current Industry 4.0 applications as well as energy and cost optimisation concepts for the beverage industry.

NORD DRIVESYSTEMS will introduce nsd tupH, among other things. This a surface conversion system that protects against corrosion and chemicals as well as high-pressure and steam jet cleaning. nsd tupH makes aluminium geared motors as resistant as stainless steel products, is significantly more effective than anti-corrosion paints and offers excellent value for money.

Drive systems count among the main consumers of energy in industry. Energy efficiency is therefore a major issue. The new energy-efficient smooth motors of NORD DRIVESYSTEMS have higher efficiency than previous models and thus contribute to the reduction of operating costs. Their smooth surfaces make them especially suited for applications in the food and beverage industry.

The successful NORDBLOC.1 series was also expanded. With the new two-stage bevel gear units for output torques of up to 50 Nm, high-efficiency helical bevel gear units (in addition to worm gear units) are now available as well for the small load range. These gear units have a very high mechanical load-bearing capacity and are resistant to high forces on the output shaft. The new models are available for gear ratios ranging from 3.03 up to 47.67:1. They are added to the current series that now consists of six sizes with torques of up to 660 Nm.

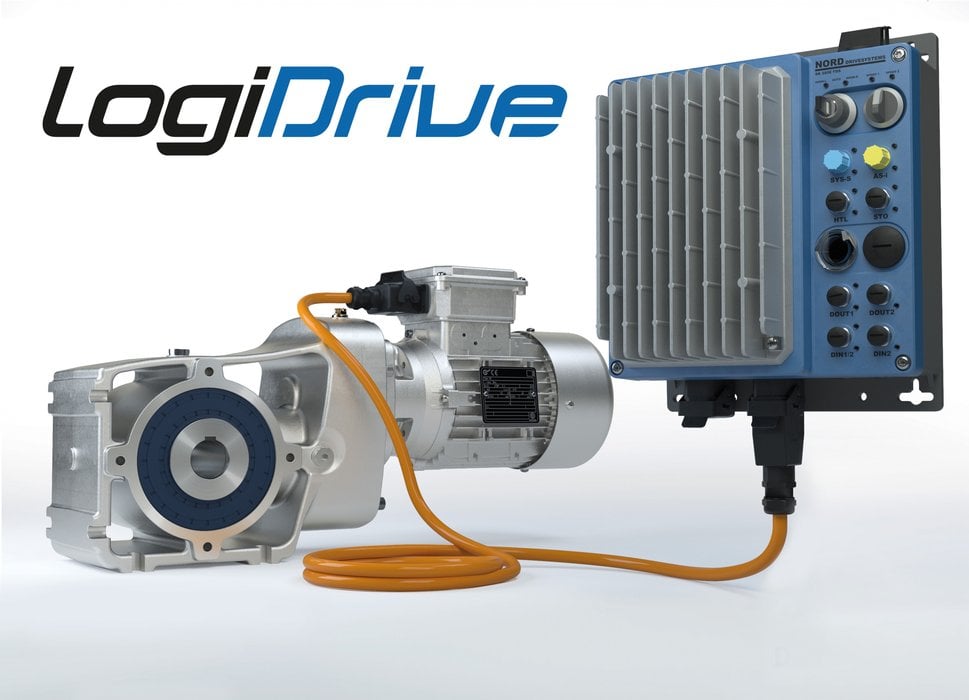

Different gear unit and motor types, sizes, options and gear ratios often result in a large variety of drive versions. A reduction in variety can result in optimised processes and costs. The high-efficiency two-stage bevel gear units with IE4 synchronous motor, power plug and ready-made cable offer a solution for intralogistics in the beverage industry. Advantages: considerable reduction of spare part stocks; service friendly using plug-and-play technology; compact, space-saving design as well as 25 percent weight savings because of a lightweight aluminium housing.

NORD has now expanded the product range of industrial gear units to eleven sizes. This makes NORD DRIVESYSTEMS the only manufacturer that produces modular industrial gear units with an output torque of up to 250,000 Nm in a one-piece unicase housing. The design principle was developed at NORD in 1981 and it ensures maximum radial and axial load-bearing capacity.

Extend service intervals and reduced downtimes – these become possible with predictive maintenance. The collection, analysis and transmission of drive and application data permit the as-required planning of maintenance assignments based on the production capacity. Maintenance costs are reduced and the drive's service life extended.

From unpacking, conveying and cleaning, filling, sealing and labelling to packaging and palletising, NORD DRIVESYSTEMS offers a variety of reliable, efficient and safe solutions for the beverage industry. You will find NORD DRIVESYSTEMS at the CBST in building N1, booth 1A02.