www.industry-asia-pacific.com

19

'16

Written on Modified on

Alihankinta Subcontracting Fair 2016, Tampere Exhibition and Sports Centre (TESC) Tampere, Finland, September 27-29 Ovako Stand: A1030

New hollow bar material and enhanced service and distribution operation launched by Ovako

At this year’s Alihankinta Subcontracting Fair in Tampere, Finland, Ovako will launch its new hollow bar M-Steel® 280 developed to offer component manufacturers design, machinability and cost advantages while also promoting its greatly increased service package and distribution operation in Finland, Ovako Metals Oy Ab.

Both enhanced offerings are intended to provide customers with significant advantages, both in terms of material consistency and availability, with a range of customized services that are fine tuned to fully meet, or even exceed customers’ expectations and improve their competitive edge.

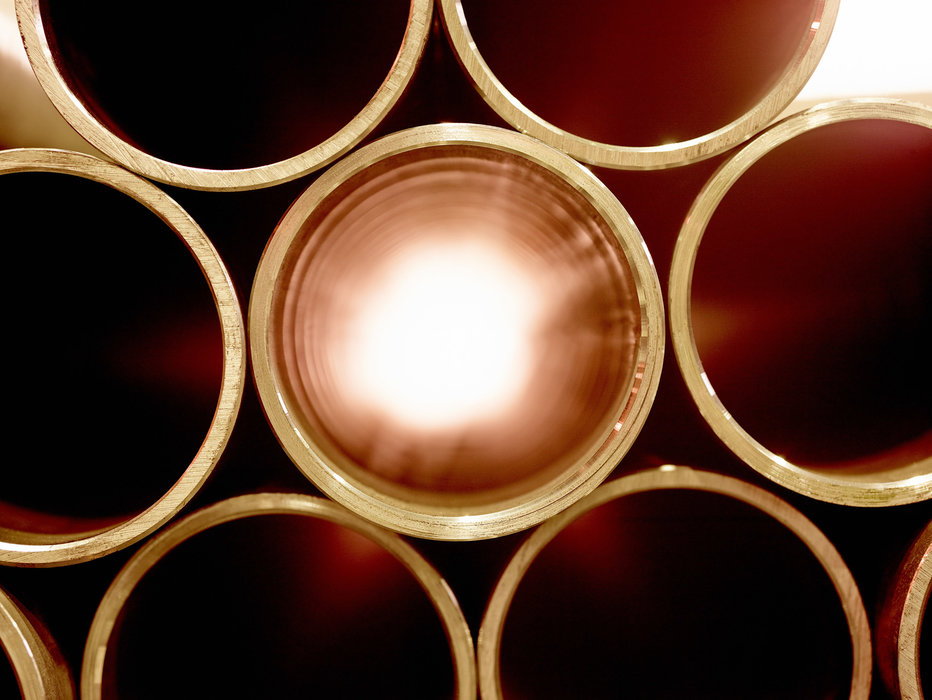

Developing the new M-Steel 280, a low carbon, micro alloyed steel 20MnV6 M, as hollow bar makes it suitable for even more demanding applications by combining high strength with excellent machinability. Because the material is based on M-Steel technology, which stands for machinability, it also facilitates higher cutting speeds and, conversely, superior tool life.

Seminars on the new M-Steel 280 hollow bar will be held in the Ovako stand on each of the three days of the exhibition. On Wednesday, September 28th, Åke Nilsson, Product & Application Turning Specialist, Sandvik Coromant Sverige AB, will present a seminar on machining advantages using M-Steel.

“M-Steel technology is unique as it enhances the machining process by forming a protective film on the cutting tool. This promotes increased cutting speeds, while extending tool life, reducing tool changes and enhancing productivity,” explained Göran Nyström, Executive Vice President of Group Marketing and Technology at Ovako. “New hollow bar M-Steel 280 not only reduces machining time; it also means customers can increase their productivity without the need for capital investment.”

A major advantage of M-Steel 280 hollow bar, close to finished component sizes, is that its use can eliminate a complete machining process where a central bore is required. This helps cut down on production time significantly, reduce component costs and increase profitability.

Also on the stand, steel and metals distributor Ovako Metals Oy Ab will take the opportunity to highlight the latest facilities which have been added to its distribution centre in nearby Tampere. The centre now boasts the capability to provide customers with a complete first stage in the production chain.

“Our extensive experience as a distributor for companies in the Finnish market, including Ovako, covers a comprehensive range of materials including low alloy carbon steels, engineering steels, carbon steel thin plates, stainless steels, brass and copper,” said Heikki Nyholm, Managing Director Ovako Metals Oy Ab, in Finland. “We provide stockholding, material purchasing, warehousing, cut to length, logistics as well as technical advice and full customer support.”

In addition, Ovako is arranging an evening customer visit to its local Tampere distribution centre during the week of Alihankinta, so that visitors can see the enhanced facilities and new capabilities available to customers.

Heikki Nyholm added, “Subcontracting is very much about trusted partnerships. Visitors to our stand will be able to see how Ovako works closely with its customers to optimize material selection, quality and consistency in order to bring performance and cost advantages across their operations.”

For more information, visit: www.ovako.com