WORLD’S FIRST COMPLETE 3D SOLUTION:

XG-X SERIES VISION SYSTEM

KEYENCE releases the first all-in-one 3D measurement and inspection package featuring the best laser profiling technology and image processing algorithms. The brand new XG-X vision system makes 3D setup and programming easier than ever with a new user interface and programmable encoder. The XG-X combines high-resolution 3D height images with ultra-high speed processing enabling inspection that cannot be done with conventional laser profiling or traditional 2D imaging.

3 Keys to 3D Success

BEST LASER PROFILING TECHNOLOGY

- 64,000 profiles per second

- High-resolution height profiling

MOST POWERFUL 3D IMAGE PROCESSING

- Real-time Vibration Correction

- Simultaneous 2D/3D imaging

IDEAL PROPORTIONAL IMAGE

- Easily synchronize dedicated encoder

- Up to 150,000 pulses per revolution

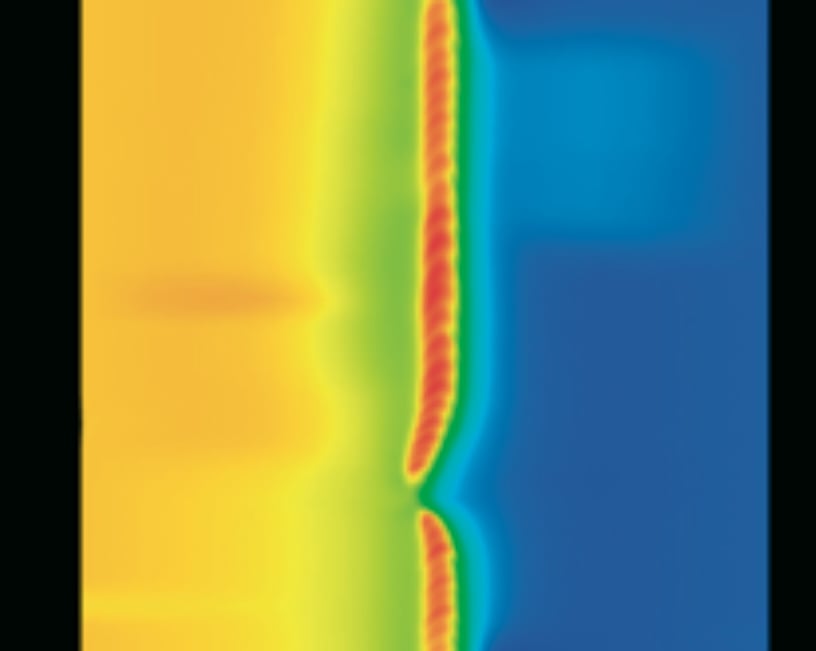

Welding Seam Inspection:

Traditional 2D area cameras:

Difficult inspection due to the unstable

surface condition of workpieces.

NEW! KEYENCE XG-X 3D Solution: Stable inspection is possible without being influenced by the surface condition of workpieces.

Traditional 2D Image versus 3D XG-X Image