www.industry-asia-pacific.com

25

'22

Written on Modified on

Will high-tech composites replace traditional materials?

MATMATCH: How materials-based improvement can change the industry.

Numerous science and engineering-based advancements have led to conclusions that the properties of composite materials are often superior to more traditional choices. Here, Emily Newton, guest author for materials database Matmatch, looks at some of the advantages that make them so promising.

Improving sustainability

Global focus is on urgent matters like climate change and excessive waste production. People are increasingly concerned with developing sustainable materials to replace those that will likely get discarded more frequently. Many eco-friendly composite materials can fill the need.

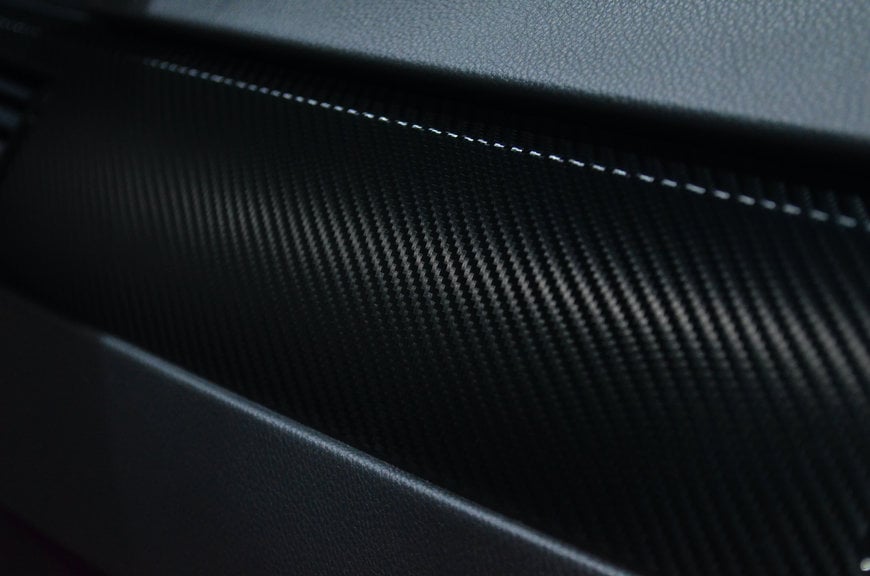

Carbon-fiber composites are popular alternatives to replace conventional metals used for everything from airplane parts to golf clubs. However, most of them are virtually impossible to fix or recycle once they break.

A new advancement by researchers at the University of Washington could overcome that downside. The team created a new material as light and strong as conventional carbon-fiber composites but easy to repair if it cracks. People can repeatedly fix the damage traditionally or with radio-frequency-based heating. This material is within a relatively new category called carbon-fiber-reinforced vitrimers (vCFRP). Unlike other carbon-fiber composites, this material allows linking, unlinking, and relinking without undermining strength or hardness.

An advantage of composite materials is that they can surpass their original properties, such as reclaimed wood treated for heat resistance. That means people may be surprised as they learn more about how composites could change the characteristics of common materials they thought they knew well.

Enhancing essential processes

People who work with composite materials often investigate how they could help users improve their processes. For example, composite screws are common choices for assembling decking because they’re typically denser than traditional wood versions. They also have finer threads and comparatively smaller heads, making them easier to drive into decking.

Improving screws can save on labor costs and increase the chances of obtaining great results, and this is just one example. Ways to strengthen an existing process could become apparent at virtually any stage, from designing a product to putting it through quality checks.

Much of the ongoing work associated with composite materials concerns futuristic approaches, such as applying robotics. For example, Rolls-Royce has a new dedicated facility for developing new composite materials. One of the approaches there concerns using robots to help make composite fan blades used in jet engines.

Each component has approximately 500 layers of carbon-fiber material, each applied in a fully automated process supervised by factory workers. Robots lift and move the parts between assembly line stations, ensuring a smooth, efficient operation.

Futuristic systems are not the only highlight of composite materials. There has been valuable research into making the materials themselves accelerate factory processes. Researchers have developed a composite laminate that changes colors in response to deformation. They believe this will allow detecting problems at earlier stages and alert people to possible material failures. People have so far only used the material in the lab. However, if it works as well as the developers hope it will, the innovation could improve processes in numerous ways.

For example, it could prevent workers from manufacturing composite pieces with internal weaknesses and minimize future recalls. The team also reported that their new material, comprised of layers, is break-resistant and lightweight. Since those are among the most desirable properties of composites, this invention could have broad applications and appeal.

Furthering material-based improvements

Another one of the advantages of composite materials is that they enable engineers and scientists to develop new options that meet needs not addressed by conventional choices. People are always looking for feasible ways to improve products. Composites often show the way forward.

Nonwoven fabrics are those derived from bonding fiber that does not require knitting or weaving. Researchers recently created a new composite material that falls into this category. They believe their innovation could be ideal for medical products, such as bandages and masks.

Tests showed that the new fabric was more absorbent than traditional options. It also performed well in stretch-recovery tests, suggesting the material would hold up well to repeated use. The team acknowledged that although other options have good breathability and stretch capabilities, the choice to add cotton should provide another noticeable benefit.

Other research has looked at changing to material on the screens in smartphones. An international research team’s project resulted in a glass composite that could minimize screen breakage plus provide a brighter display. The materials are based on lead halide perovskites, which work like miniature solar panels because they catch and store energy. The basic approach is to wrap nanocrystals into a porous glass.

That method should improve current nanocrystal technologies used for device screens. The group working on this project cautioned that, while they believe their techniques are scalable, there’s still a lot of work to do. They need to figure out the best ways to create materials with the desired properties.

These are just some of the many advantages of composite materials that get people excited about what the future holds. Traditional materials still have a place in numerous instances, but these examples show the benefits of working with composites to generate specific results. By using a materials database like Matmatch, material engineers can search for and look ahead at different composites that can replace traditional material.

www.matmatch.com