www.industry-asia-pacific.com

26

'20

Written on Modified on

ELECTROCALORIC SOLID STATE COOLING MODULE WITH THERMAL DIODES (EKDM)

Electrocaloric Cooling: In the EKDM funded research project (Electrocaloric-Diode-Coolingmodule, ger. EKDM), four small and medium-sized enterprises (SME) are working together with a Fraunhofer Institute on the research and development of an electrocaloric solid state cooling module with thermal diodes for cooling in existing and innovative applications.

Refrigeration plays an important role in a variety of applications, such as in the food industry, in households, in medicine or in transport. Conventional technologies of cold generation by means of compression and sorption cooling machines or thermoelectrics are technically maxed out. Solid-state cooling processes based on electrocaloric technology promise an increase in energy efficiency and do not use harmful refrigerants. This makes them particularly attractive in terms of meeting climate policy and environmental targets. Within the project, ceramic, electrocaloric components are being developed and an innovative system approach based on thermal diodes is being investigated.

How does electrocaloric solid-state cooling work?

When an electric field is applied to electrocaloric (EC) materials, the electric dipole moments align themselves in the electric field. According to the laws of thermodynamics, this is accompanied by an increase in temperature of the material. The resulting heat is dissipated via a heat sink, causing the material to cool down again to the initial temperature. When the electric field is subsequently removed, the order in the material decreases and the temperature drops below the initial temperature. Now the material can absorb thermal energy from a heat source. The electrocaloric effect is reversible and can therefore be used cyclically in a solid-state cooling system.

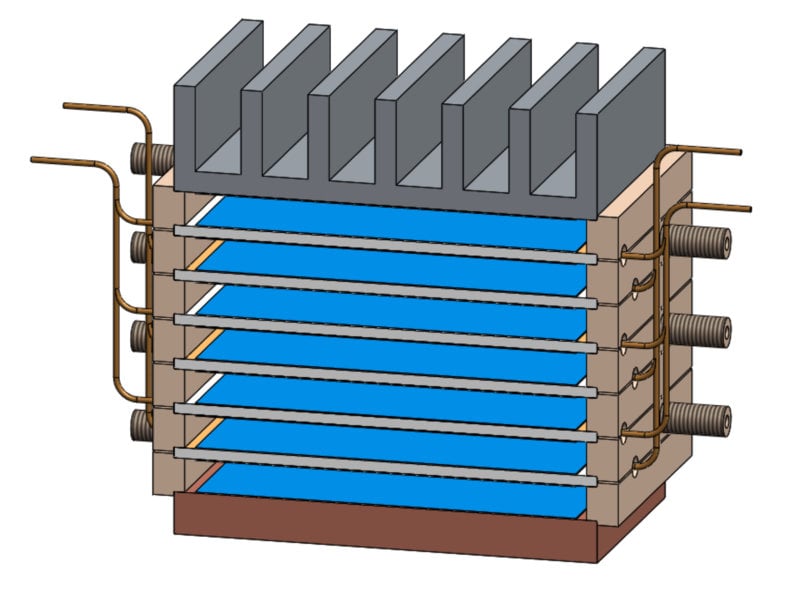

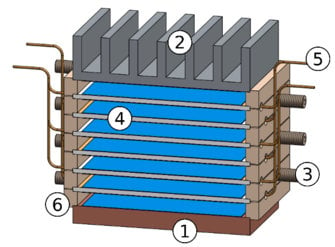

CAD concept for an EKDM (1: heat source, 2: heat sink, 3: filling nozzle, 4: electrocaloric components, 5: electrical connections, 6: spacer)

In an innovative system approach, the electro-caloric heat is transferred via evaporation and condensation of water. A rectified heat flow from the heat source to the heat sink is made possible by the implementation as a thermal diode in an analogous way to the Planar Jumping-Drop Thermal Diodes [1]. The cooling system is designed as a compact solid-state assembly consisting of several stages of electrocaloric diode modules.

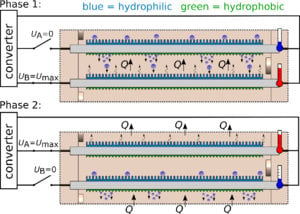

Schematic illustration of how the EKDM works

The principle of operation of an electrocaloric diode module (EKDM) is shown schematically. The evacuated chambers between two electrocaloric components contain small amounts of water that accumulate on the hydrophilic side of the chamber. When an electrical voltage is applied to the lower EC component (phase 1), it heats up and causes the water to evaporate. The water vapor condenses on the cold surface of the upper EC component, releasing the phase transition heat. Due to the hydrophobic properties of this surface, the water does not remain there, but re-collects on the hydrophilic surface of the lower EC component. Subsequently, the electrical voltage is applied to the upper EC component (phase 2). Since there is no water for an evaporation process on the hydrophobic side, the directed heat flow only takes place from the hydrophilic to the hydrophobic side, but not vice versa.

What are the responsibilities of the project partners?

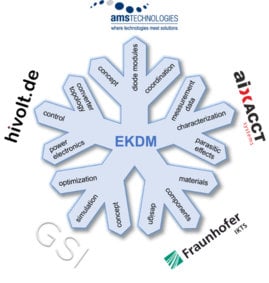

Cooperation of the partners in the EKDM project

In order to achieve the project goals, all partners work closely together in an interdisciplinary team. The individual project segments are summarized schematically. GSI Technology UG carries out the thermal simulations and the design of the overall system. The Fraunhofer Institute for Ceramic Technologies and Systems IKTS synthesizes the EC materials and provides the required components based on these materials. AMS Technologies AG focuses on the experimental implementation of the thermal diode modules. hivolt.de GmbH & Co.KG develops the necessary high-voltage and circuit electronics. aixACCT Systems GmbH develops a characterization process for the EC materials and components. The materials and components developed in the project are investigated with this method and the measurement data is supplied as input for the simulation.

What are the objectives of the project?

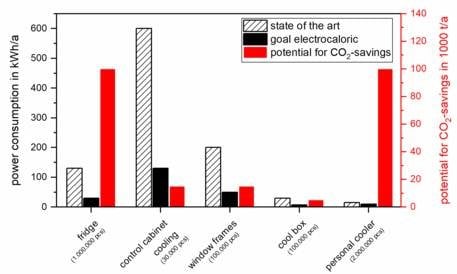

The work in this project is intended to show that electrocaloric solid state cooling modules have the potential to make cooling more efficient in existing applications and also to open up new and innovative applications. At present, electrocaloric technology is still at early stages of development. So far, there are only a few prototypical setups of electrocaloric systems on a laboratory scale. In the future, existing applications such as smaller refrigerators, cabinet cooling or cooling for telecommunications and digital TV transmitters can be realized much more efficiently with such a cooling system. In addition, there are completely new cooling concepts such as room climate control via heating and cooling functions in window frames, mobile cooling boxes (bicycle courier or drones) and personal coolers. The possible CO2 savings compared to existing technologies.

Expected EKDM goals with the associated potential for CO2-savings

The project focuses on the development of a system-related technology that increases energy efficiency in cooling applications and minimizes the emission of greenhouse gases. This is a direct link to the guideline for funding projects of the Federal Ministry of Education and Research (ger. BMBF) on the topic "SME innovative: Resource- and Energy-Efficiency" and is listed under the funding code 01LY1921A.

www.amstechnologies.com