www.industry-asia-pacific.com

22

'20

Written on Modified on

SKF extends the JIS compliant ball bearing units with its new 300 series for contaminated environments

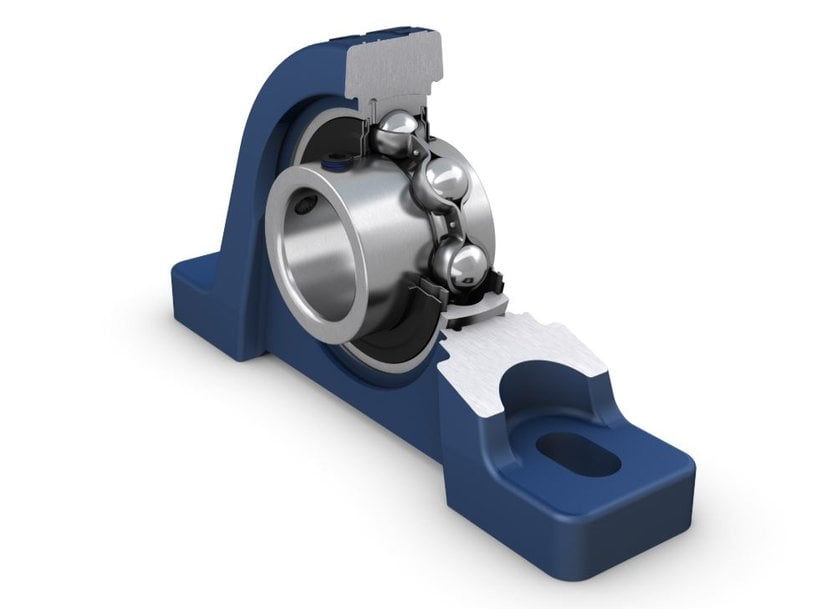

With its new UC 300 series of ball bearing units, SKF has increased protection against contamination in heavy-duty applications.

The new UC 300 ball bearing units from SKF feature superior sealing and stronger locking and are interchangeable with all JIS (Japanese Industrial Standards) housings. The introduction of the new products extends SKF’s UC range of ball bearing units, offering a comprehensive choice of reliable bearings that are available with short lead times.

The new UC 300 is ideal for use in highly contaminated industrial environments, where bearing life can often be shortened through the ingress of process materials such as mud, dust, wood chips or water. To overcome these problems, the UC 300 series is equipped with field-proven sealing technology. It also has asolid base design of housing to minimise areas that might otherwise trap dirt or moisture.

When bearings are subject to systemic vibration, the results can include increased shaft imbalance, misalignment and loosening of locking mechanisms. The UC 300 series addresses these problems with its robust construction and high strength locking system. Designed to cope with operations characterised by higher peak loads and lower rotation speeds, each unit also features a grub screw locking system set at an angle of 62°, which gives even better holding power.

“Whatever their need, engineers can now find proven, high-quality and reliable ball bearing units from a single, quickly accessible and trusted source,” says Jerome Pommereul, SKF Product Manager. “Thanks to their greater contamination and vibration resistance, they will last longer, maximise the performance of rotating equipment and minimise productivity losses due to bearing failure. Customers will also see cost savings through fewer replacements and repairs. “If you are an OEM, the reliability of our bearings will reduce operational costs relating to warranty cases, engineering and development.”

UC 300 series units are available with bores ranging up to 100 mm. Typical applications will include conveyors, belt pulley and chain transmissions, and cranes. They will be of particular benefit in areas such as material handling, agricultural, construction machinery, HVAC systems, textile industry, metals and mining.

www.skf.com