www.industry-asia-pacific.com

04

'20

Written on Modified on

Cost reduction through efficient energy-saving motors

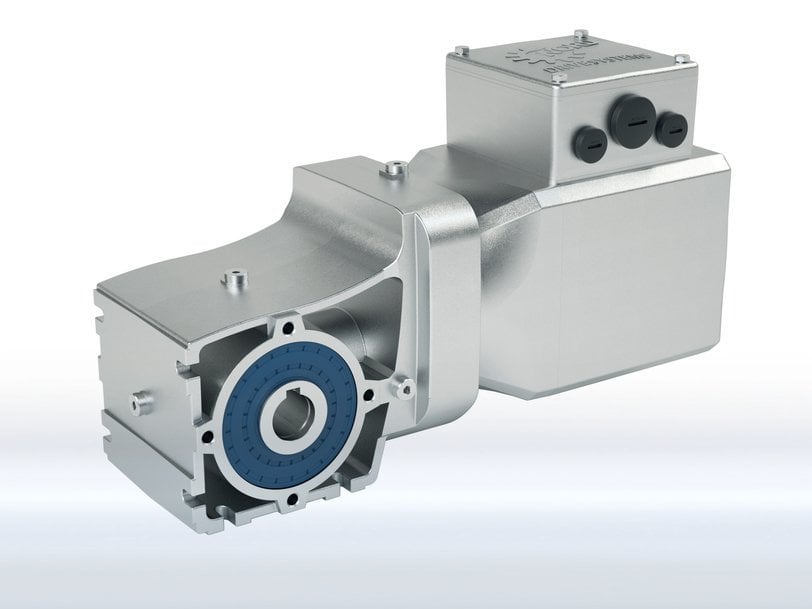

NORD DRIVESYSTEMS has developed a new synchronous motor with significantly higher energy efficiency (IE5+). It is a supplement to the standardised geared motor variants of the LogiDrive systems and is particularly suitable for reducing the number of variants. This makes the IE5+ synchronous motor particularly suitable for use in intralogistics.

The energy-efficient latest generation permanent magnet synchronous motor has considerably lower losses than the current IE4 series. The unventilated smooth motor achieves its high efficiency that, at times, is significantly above efficiency class IE5 via a wide torque range – and is optimally suitable for the operation in the partial load range. The compact IE5+ motor offers a high power density with less installation space and will be initially launched in a size for power ranges from 0.35 to 1.1 kW with a continuous torque from 1.6 to 4.8 Nm and speeds from 0 to 2,100 min-1. Direct motor attachment as well as NEMA and IEC motor attachments are available. An integrated encoder and an integrated mechanical brake are optionally available.

Due to constant torque over a wide speed range, IE5+ motors allow a targeted reduction of variants. This minimises administrative expenses, and enables leaner manufacturing, logistics, storage and service processes. The new IE5+ motor generation combines the benefits of the modular system and higher efficiency with the possibilities of reducing variants, and pays for itself within a short time. The new IE5+ motor can be combined with NORD gear units and drive electronics as a modular system and will be available from the second quarter of 2020.