www.industry-asia-pacific.com

10

'19

Written on Modified on

World’s smallest and lightest fiber laser head will be a game changer in laser marking

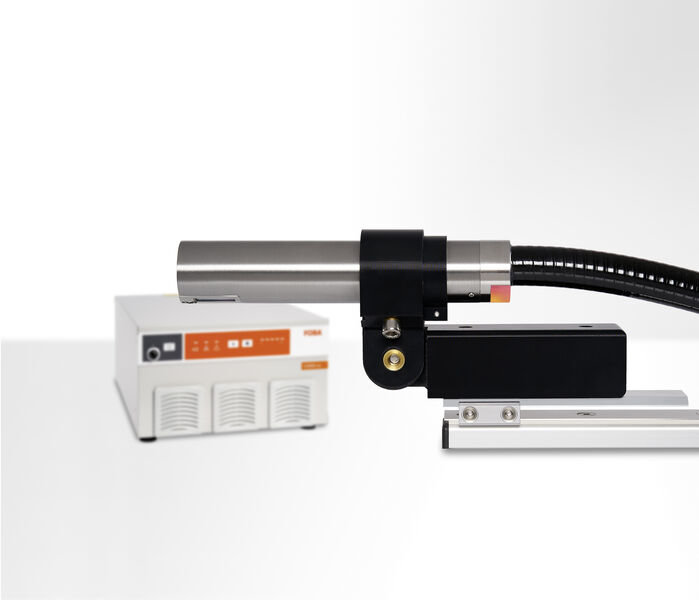

FOBA's latest innovation is available on the market after having had its first introduction at some recent tradeshows: Just over 20 centimeters long and around 630 grams light are the dimensions of the new Vector Scan laser marking head called Titus. Being part of the new 20-watt or 30-watt FOBA fiber laser marking systems Y.0200-xs / Y.0300-xs, the novelty offers unprecedented flexibility in terms of line integration, usability and speed.

Due to its small format and tubular shape, easy mounting with a clamping bracket and an optional supply line up to ten meters long, the Titus™ marking head can be easily integrated into a wide range of production lines. Its flexibility is also based on an optional straight or inclined by 90 degrees exit angle of the laser beam and the ability to adjust the marking field size to the application requirements.

During installation, a saving of up to 90 percent of the time normally required is possible. Adjustment and focus determination as well as application setup are significantly accelerated by the integrated focus finder and pilot laser.

The new laser marking system was developed in collaboration with and according to the needs of system integrators and the automotive industry. "With Titus™, we are ahead of the market, because such a compact, fast-to-install and easy-to-use, even remotely operable marking laser has never been there," says product manager Philipp Febel.

The advantages of the new fiber laser not only result from its design, but also from the device software. All three available user interfaces from FOBA can be used to operate the system: In addition to the user interfaces FOBA MarkUS and FOBA Draw, the new remote FOBA Go software is particularly suitable, which can be operated by any PC, touch display, tablet or other mobile device. All common industrial communication protocols are also compatible.

The maintenance of the system is simplified by the possibility of a minute-fast removal or conversion as well as a dust-protected lens. In harsh production conditions, the IP65 or IP69 standard of the marking head as well provides protection against dust and moisture. The low maintenance requirement also results from the very small number of wearing parts.

This new laser generation will redefine line compatibility, ease of installation, ease of use and speed. FOBA wants to help its customers with the innovative laser system Y.0200-xs / Y.0300-xs and the unique scanning head Titus™ to fully exploit their possibilities in the direct marking of their components and to achieve optimum profitability.

www.fobalaser.com