www.industry-asia-pacific.com

26

'19

Written on Modified on

Flexible system partnership with a comprehensive service concept

Baumüller equips the Simpac MX and SX servo press series with highly dynamic drive and automation solutions.

In spring 2019, Baumüller signed a cooperation agreement with press manufacturer Simpac. This encompasses the supply of drive and automation systems for the new MX and SX press series.

“For us, this is a further step in the standardization process, which will not only benefit Simpac. In addition to a highly efficient drive concept, in future our customers will also benefit in terms of maintenance and service,” explains Bernd Moritz, Chief Technology Officer at Simpac Inc. in South Korea and Managing Director of Simpac Europe GmbH.

Complete solution from a single source for highly dynamic servo presses

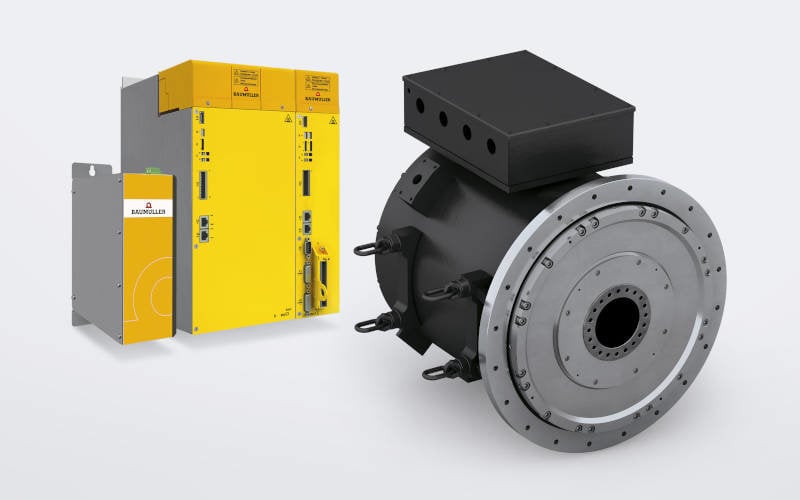

In future, Baumüller will supply Simpac with highly dynamic high-torque motors as well as complete power electronics and industrial PCs, including software for features such as motion control and curve generation.

The overall system consists of DST2 high-torque motors, which generate high torque even at low speeds. The combination of regulated infeed with the b maXX 5100 and capacitors as energy storage reduces the power supply output, and with it the energy costs. Operating costs are significantly lower than those of mechanical storage systems. The motor itself is operated on the powerful modules of the b maXX 5000 series.

Baumüller also supplies the completely wired control cabinet. All the key components, from drive controllers to machine controls, can be supplied within the Baumüller Group. The control cabinets are supplied by Baumüller Dravinja, the Baumüller subsidiary in Slovenia specializing in machine enclosures and control cabinet production. Baumüller also took on the complete engineering of the drive system. The latest generation of the powerful b maXX PCC-04, a scalable, versatile platform for demanding control tasks, serves as the machine control system.

Another advantage of the single-source drive concept is the possibility of analyzing the system in the event of a fault with the help of the remote maintenance solution. If required, remote access can be used to carry out optimization measures, e.g. reparameterization of the controllers. This Industry 4.0 solution contributes to comprehensive diagnostics and a more efficient error elimination process, resulting in higher plant availability and lower service costs.

www.baumueller.com