www.industry-asia-pacific.com

25

'19

Written on Modified on

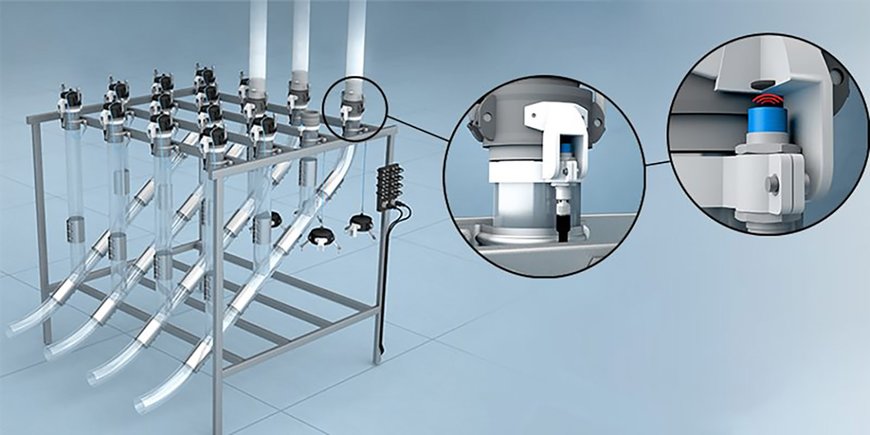

RFID technology with IO-Link connectivity eliminates hose-coupling errors in fluidized pneumatic-transport systems

Bulk-handling- and pneumatic-transport-system designers use RFID technology to eliminate connection errors at manual hose-coupling stations for fluidizable materials.

Coupling stations, with IO-Link-enabled read/write modules (RWMs) mounted on each outlet pipe, use manual quick-release hoses to feed materials to multiple machines. RFID tags, mounted integrally within each hose coupling and blanking cap, identify the mating parts uniquely, allowing individual outlet/hose combinations to be verified at the time of connection.

Customer value

- Industry-standard IO-Link interface ensures reliable out-of-the-box connectivity

- Dual-mode read-write modules deliver ultimate flexibility

- Standard I/O mode operation provides decentralized, local intelligence

- IO-Link mode operation provides centralized intelligence

- Plant-wide commonality of RWM hardware minimizes spares inventory holding

- Integral M12 connectors ensure easy installation and replacement

Specific product advantages

- IO-Link V1.1 compatibility

- Robust metal housings with PBTB sensing faces

- Sensing distances up to 60 mm

- Reconfigurable remotely or via Master Tag