www.industry-asia-pacific.com

09

'25

Written on Modified on

The Cost of Unplanned Downtime Due to Inefficient Maintenance Practices

Organisations that prioritise maintenance as a strategic function will not only reduce downtime but also gain a competitive edge, says Milton D’Silva.

A loose bolt or a leaky joint can spell trouble. Photo by Cang Hai on Pexels.

Downtime, in the industrial context, refers to periods when production or operations are halted, whether planned or unplanned. When planned, it is an organised happening and the time used for scheduled maintenance activities, tool changes, periodic servicing, and preventive checks on all equipment for wear and tear – something that is an accepted industry practice. However, unplanned downtime is a dreaded word, whether caused by equipment failures or material shortages. Such downtime significantly impacts industry by reducing production, leading to financial losses, delayed shipments, and potentially damaging customer relationships.

Manufacturing today has become a complex operation with an interplay of advanced technologies, either legacy machines with various states of automation operating under human supervision; or extremely sophisticated operations with fully automated or autonomous connected machines that function with minimal manual intervention. While the chances of human error can never be ruled out, even equipment failure is not a rare occurrence. Breakdowns happen for a myriad of reasons and not necessarily because someone has thrown the metaphorical spanner in the works.

One of the principal reasons for unplanned downtime is inefficient maintenance practices that sooner or later end in machinery breakdown and disrupt production. It may be recalled that the Space Shuttle Challenger exploded just 73 seconds into its flight in January 1986, killing all seven crew members aboard, in what is termed as one of the worst space disasters. Later, it was found that the failure was caused by a faulty seal, specifically an O-ring, in the right solid rocket booster, which failed to properly seal the joint, allowing hot exhaust gases to escape and ignite the external fuel tank. What was really appalling is that engineers at NASA were aware of, and failed to address, a known defect. Even if this is an extreme example, the jarring sound of a bearing or traces of oil around joints, are sure indications of an impending breakdown, the consequences of which could be a huge monetary loss or worse, if the root cause is not addressed promptly.

Unplanned downtime caused by material shortages are a different category. These may happen due to bad inventory planning, which would be really stupid, but more often, are caused by supply chain disruption that may happen due to natural calamities or any other emergency situation like war, or to cite a recent example, a pandemic. This article seeks to explore at length the issues of inefficient maintenance practices that contribute to unplanned downtime in industry, leading to huge losses.

Breakdowns happen for a myriad of reasons. Image by Freepix

The true cost of downtime

An unplanned downtime may initially appear like a temporary inconvenience, something that could be set right in minutes, and sometimes it could well be the case; but chances are it is something far more serious with unanticipated consequences. Every minute of downtime means the machines are idle and there is no production. In a high-volume manufacturing industry, this means loss of thousands or even millions of dollars in revenue, depending on the duration of the outage. For example, in the highly competitive automotive or heavily in demand semiconductor industries, even a one-hour halt can cause a significant backlog and delay in supply chains.

Financial loss is just one aspect of it and the cascading effect has a much higher price besides lost production. Increased labour cost, overtime, equipment damage, and above all, loss of reputation due to failure to meet deadlines in the age of just-in-time production, penal clauses in contract for late deliveries, etc., add to that. Hence it is of utmost importance to understand the real cost of downtime for companies to realise all the implications, and prepare them to adopt the right strategies to maintain efficiency, profitability, and competitiveness.

According to a much referenced report by Aberdeen Strategy & Research, 82% of companies have experienced unplanned downtime over the past three years and that unplanned downtime can cost a company as much as $260,000 an hour.

A 2023 ABB report, based on a survey conducted by Sapio Research of 3,215 plant maintenance leaders across the globe, found that outages cost the typical industrial business a hefty $125,000 USD per hour. A significant 69 percent of plants experience unplanned outages at least once a month.

A more recent survey by Siemens titled ‘The True Cost of Downtime 2024’ gives a fairly good idea of the losses incurred by four industry segments for just an hour’s unplanned downtime, which varies from industry to industry. Just sample this:

Downtime, in the industrial context, refers to periods when production or operations are halted, whether planned or unplanned. When planned, it is an organised happening and the time used for scheduled maintenance activities, tool changes, periodic servicing, and preventive checks on all equipment for wear and tear – something that is an accepted industry practice. However, unplanned downtime is a dreaded word, whether caused by equipment failures or material shortages. Such downtime significantly impacts industry by reducing production, leading to financial losses, delayed shipments, and potentially damaging customer relationships.

Manufacturing today has become a complex operation with an interplay of advanced technologies, either legacy machines with various states of automation operating under human supervision; or extremely sophisticated operations with fully automated or autonomous connected machines that function with minimal manual intervention. While the chances of human error can never be ruled out, even equipment failure is not a rare occurrence. Breakdowns happen for a myriad of reasons and not necessarily because someone has thrown the metaphorical spanner in the works.

One of the principal reasons for unplanned downtime is inefficient maintenance practices that sooner or later end in machinery breakdown and disrupt production. It may be recalled that the Space Shuttle Challenger exploded just 73 seconds into its flight in January 1986, killing all seven crew members aboard, in what is termed as one of the worst space disasters. Later, it was found that the failure was caused by a faulty seal, specifically an O-ring, in the right solid rocket booster, which failed to properly seal the joint, allowing hot exhaust gases to escape and ignite the external fuel tank. What was really appalling is that engineers at NASA were aware of, and failed to address, a known defect. Even if this is an extreme example, the jarring sound of a bearing or traces of oil around joints, are sure indications of an impending breakdown, the consequences of which could be a huge monetary loss or worse, if the root cause is not addressed promptly.

Unplanned downtime caused by material shortages are a different category. These may happen due to bad inventory planning, which would be really stupid, but more often, are caused by supply chain disruption that may happen due to natural calamities or any other emergency situation like war, or to cite a recent example, a pandemic. This article seeks to explore at length the issues of inefficient maintenance practices that contribute to unplanned downtime in industry, leading to huge losses.

Breakdowns happen for a myriad of reasons. Image by Freepix

The true cost of downtime

An unplanned downtime may initially appear like a temporary inconvenience, something that could be set right in minutes, and sometimes it could well be the case; but chances are it is something far more serious with unanticipated consequences. Every minute of downtime means the machines are idle and there is no production. In a high-volume manufacturing industry, this means loss of thousands or even millions of dollars in revenue, depending on the duration of the outage. For example, in the highly competitive automotive or heavily in demand semiconductor industries, even a one-hour halt can cause a significant backlog and delay in supply chains.

Financial loss is just one aspect of it and the cascading effect has a much higher price besides lost production. Increased labour cost, overtime, equipment damage, and above all, loss of reputation due to failure to meet deadlines in the age of just-in-time production, penal clauses in contract for late deliveries, etc., add to that. Hence it is of utmost importance to understand the real cost of downtime for companies to realise all the implications, and prepare them to adopt the right strategies to maintain efficiency, profitability, and competitiveness.

According to a much referenced report by Aberdeen Strategy & Research, 82% of companies have experienced unplanned downtime over the past three years and that unplanned downtime can cost a company as much as $260,000 an hour.

A 2023 ABB report, based on a survey conducted by Sapio Research of 3,215 plant maintenance leaders across the globe, found that outages cost the typical industrial business a hefty $125,000 USD per hour. A significant 69 percent of plants experience unplanned outages at least once a month.

A more recent survey by Siemens titled ‘The True Cost of Downtime 2024’ gives a fairly good idea of the losses incurred by four industry segments for just an hour’s unplanned downtime, which varies from industry to industry. Just sample this:

- The Automotive industry faces the most significant financial repercussions from downtime, with every unproductive hour costing a staggering $2.3 million. This figure represents a twofold increase from 2019.

- Heavy Industry, with the high cost of halting large-scale machinery, has seen an even more dramatic rise in downtime costs, with a fourfold increase over the past five years.

- The FMCG sector has managed to keep downtime costs stable, despite fluctuations in global demand.

- In the Oil & Gas sector, the cost of downtime fluctuates in tandem with oil prices. During periods of high oil prices, such as early 2022, downtime costs soared. However, in 2023, as oil prices stabilised between $60 and $80 per barrel, downtime costs mirrored those of 2019.

The era of AI-based predictive maintenance is here. Image source: ABB

Common causes of inefficient maintenance

At the very heart of unplanned downtime caused due to maintenance issues is the still widely prevalent culture of reactive maintenance, or the ‘run to failure’ mindset. Companies that follow this approach are still relying on the age-old practice of attending to equipment only after it has failed, which leads to unexpected shutdowns and the consequences that follow. The immediate outcome that results from this is emergency repairs and parts replacements, which is always more expensive than planned maintenance. While equipment failure is a primary cause of unplanned downtime, especially when reactive maintenance is the only strategy employed, there are other factors that contribute to unplanned downtime. These include, apart from poor maintenance practices, operator error, inadequate training and lack of proper planning from inventory to workflows.

Poor asset visibility and tracking is another reason that contributes to unplanned downtime. This refers to a lack of real-time, accurate information about the location, condition, and usage of assets – the machinery, control panels and other ancillary equipment that leads to inefficiencies and increased risk. So when a crisis hits in the form of sudden stoppage of the line, in the absence of precise knowledge of all assets and their location, it becomes difficult to identify, predict, diagnose and then proactively address potential issues with the equipment.

With poor asset visibility, what inevitably follows is lack of predictive maintenance capabilities in maintenance teams, which in turn makes it difficult to anticipate equipment failures. A well maintained plant is usually also well looked after from the maintenance perspective. What is unseen is also ignored until it is too late to pay attention to, delaying necessary repairs, and ultimately increasing the frequency and duration of breakdowns. Without predictive capabilities, maintenance teams are reactive rather than proactive, leading to costly and disruptive downtime. This makes a sound argument in favour of a proactive maintenance strategy. When maintenance teams lack predictive capabilities, they are more likely to react to breakdowns, resulting in increased downtime frequency and duration.

Another significant factor in the series of inefficient maintenance practices is inadequate training and skill gaps in maintenance teams. This results in human errors, hindering effective maintenance, and potentially leading to equipment failures and safety issues. Such skill gaps can result in a variety of problems, including incorrect procedures, missed preventive maintenance tasks, delayed or ineffective troubleshooting, and an overall reduction in the team's ability to maintain equipment reliably. Without the necessary skills to diagnose and fix issues quickly, maintenance teams may spend more time troubleshooting, leading to prolonged downtime while waiting for external help or resources.

It is pertinent to note here that inefficient maintenance practices are not restricted to machinery and equipment. Today almost all industrial plants rely on a variety of software platforms to manage operations, from design and manufacturing to data collection and automation. These include Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), Computerised Maintenance Management Systems (CMMS), Supervisory Control and Data Acquisition (SCADA) systems, and Computer-Aided Design/Manufacturing (CAD/CAM) software. In addition, with increasing digitisation of plants and connected equipment, there are also vulnerabilities like bugs and cyber attacks that afflict the IT infrastructure, which also contributes to unplanned downtime. According to David Flower, Member, Forbes Technology Council, data deluge – the exponential growth of data volume, variety and velocity – is a major downtime driver today. In a signed article on the Forbes portal – The True Cost Of Downtime (And How To Avoid It) – Flower emphasises that legacy tech stacks that weren’t designed to handle such massive workloads can get overwhelmed, buckling under pressure. Hence periodic upgrades and regular maintenance of the IT infrastructure is critical to ensure system reliability and resilience.

In view of the causes mentioned above, what could be the logical thing to do for companies that still rely on reactive maintenance? One of the easiest things to do, to begin with, is to start keeping a meticulous record of the plant from a maintenance perspective. Proper documentation, or CMMS, can help reduce unplanned downtime in industry by centralising all maintenance information, streamlining processes, and facilitating proactive maintenance. By tracking equipment history, scheduling preventive maintenance, and optimising resource allocation, CMMS systems minimise the risk of unexpected breakdowns and improve overall equipment reliability.

Digital twins, combined with ML-based analytics, are revolutionising predictive maintenance. Image by Freepix

Industry spotlights: Real-world downtime losses

One of the worst ever recorded incidents of a maintenance related industrial disaster occurred in the Indian city of Bhopal on the night of December 2-3, 1984. The pesticide plant of Union Carbide, a global MNC, released Methyl isocyanate (MIC) – a highly toxic gas that caused over 3,000 instant deaths in the thickly populated areas around the plant. The immediate cause of the leak was corroded valves and pipelines that remained unrepaired for months. It was exacerbated by multiple factors like the shutting down of the refrigeration system meant to keep MIC cool – and thus less volatile – to save costs; the scrubber system, which neutralises toxic gas leaks, was non-functional at the time; and the flare tower, meant to burn off leaking gases, was out of service due to maintenance neglect. The case dragged on for years in Indian courts. Up to 15,000-20,000 total deaths were attributed over time due to exposure-related illnesses and hundreds of thousands were injured, with long-term health effects. In 1989, Union Carbide reached a settlement with the Indian government by paying a one time settlement amount of $470 million, which was grossly inadequate given the scale of the tragedy. It permanently damaged the credibility of Union Carbide, the company later acquired by Dow Chemicals. The Bhopal plant site was abandoned and remains contaminated to this day. Like the 1986 Challenger Space Shuttle disaster, this too is an extreme example of the terrible consequences that could result from bad maintenance practices.

Presented below are a few more cases, prominent examples from three leading industry segments, including those related to poor maintenance of IT infrastructure:

Oil & Gas/Chemical

BP Texas City Refinery Explosion (2005): In March 2005, a massive explosion occurred at BP's Texas City refinery, later attributed to the failure of critical safety and maintenance procedures. A raffinate splitter tower was overfilled, and a blowdown drum vented flammable liquid, which ignited possibly to a vehicle engine running in the vicinity. The cause was determined as deferred maintenance, outdated equipment, and ignored warnings. Inadequate inspection and safety checks allowed systemic problems to build up. The impact was severe – 15 people killed, more than 180 injured. Operations shut down, and BP faced over $1.5 billion in fines, compensation, and upgrades. This is considered one of the worst (and costliest) industrial accidents in the US.

BASF Ludwigshafen Explosion (2016): An explosion and fire occurred during routine maintenance work on a pipeline system at BASF’s main plant in Ludwigshafen, Germany. It was caused when some contract workers accidentally cut the wrong pipeline, which carried flammable materials. It was later found out that there was a lack of proper identification, communication, and risk mitigation during maintenance at the site. It resulted in the death of 5, including four firefighters, and 44 others were injured. BASF had to shut down multiple production facilities, affecting global supply chains. Financial loss ran into hundreds of millions of euros.

Shell Moerdijk Plant Outage (2014): A fire and explosion occurred at Shell's chemical plant in Moerdijk, Netherlands, due to failed maintenance on a heat exchanger. The cause was later identified as a corroded pipe that went unnoticed during maintenance checks, leading to a leak of flammable gases that ignited. As a result, the operations were halted for months, and Shell faced €200+ million in losses. Production of propylene oxide and styrene monomer—a critical input for plastics—was severely impacted.

Food Industry

Saputo Dairy UK (2019): In 2019, Saputo Dairy UK (formerly Dairy Crest), a major British cheese producer, experienced a plant shutdown at its Davidstow creamery, one of the UK’s largest cheese manufacturing sites, due to a fault in its ammonia refrigeration system — a critical part of the cooling infrastructure. The leak was traced to a failure in maintenance procedures related to the plant’s aging refrigeration equipment. There were inadequate inspections and delayed replacement of parts that should have been flagged during routine maintenance. The incident forced the partial shutdown of the plant for several days to address the safety and mechanical issues. The company incurred hundreds of thousands of pounds in direct losses, plus reputation damage.

JBS USA (2018): A critical freezer malfunction at a JBS beef processing facility in the US caused significant product losses. The root cause was a neglected component in the cooling system that had not been serviced on schedule. The incident resulted in delayed shipments, product disposal, and lost contracts.

The milk processing plant of Sachsenmilch Leppersdorf GmbH. Image source: Siemens

Automotive Industry

Toyota – Japan Production Shutdown (2023): In August 2023, Toyota had to halt operations at all 14 of its assembly plants in Japan due to a system failure in its parts ordering system. Production was completely stopped for a day across Japan. Approximately 13,000 vehicles were affected by the disruption. The root cause was later traced to insufficient disk space on a server following routine maintenance, which prevented the system from processing parts orders. Toyota operates on a just-in-time (JIT) manufacturing model. Even minor disruptions can cascade into major delays. The incident highlighted how IT infrastructure vulnerabilities—not just physical machinery breakdowns—can severely affect operations.

Nissan UK – Production Halt Due to IT Maintenance Failure (2017): In October 2017, Nissan’s Sunderland plant in the UK—the company’s largest manufacturing site in Europe—suffered unplanned downtime due to a failed IT system upgrade during scheduled maintenance. The plant was forced to halt production for nearly two days. The Sunderland facility produces over 500,000 vehicles per year, so even a short disruption had significant output and revenue implications. The failure occurred after a system maintenance upgrade did not go as planned, affecting the plant's ability to manage just-in-time supply chain operations.

Ford – Rouge Plant Explosion (2000): While older, this case underscores how maintenance neglect can have catastrophic effects. An explosion at Ford’s Rouge power plant in Michigan, caused by accumulated dust in a boiler (a maintenance oversight), led to 6 fatalities and 14 injuries. It shut down vehicle production across multiple plants due to loss of power.

These cases illustrate the importance of rigorous safety and facility maintenance practices to avoid both human and operational losses in industrial plants. The chemical and oil & gas industries are particularly sensitive to unplanned downtime, where even brief disruptions can lead to huge financial losses, safety risks, and environmental hazards. Food plants rely heavily on refrigeration and hygienic systems, which are maintenance-sensitive. A small leak or breakdown can lead to product spoilage, compliance violations, and recalls. The automotive industry, traditionally one of the most automated, is today more susceptible to IT related snafus or cyber attacks and needs robust maintenance and protection of the IT system.

The digital divide: Leaders vs. Laggards in maintenance

Technology today offers various tools that can address the issues listed above; factors that are responsible for poor maintenance practices. The good thing is many companies are adopting them to their advantage. The bad thing, as noted in the ABB Report quoted at the beginning of this article, is that 21% of the 3,215 respondents still conduct run-to-fail or ‘reactive maintenance’. Worse, they continue with the conventional practice not because of ignorance but in spite of being aware of the solutions available to address the problem.

Digital technologies, particularly those related to predictive maintenance and asset management, significantly reduce unplanned downtime due to poor maintenance practices by providing real-time data, enabling proactive maintenance, and improving overall maintenance efficiency.

This is achieved in the following ways:

1. Real-time data and monitoring with IoT sensors: Industrial Internet of Things (IoT) sensors collect data on equipment performance, temperature, vibration, and other relevant parameters. Advanced analytics algorithms analyse sensor data to identify patterns, anomalies, and potential failures. This real-time data provides maintenance teams with immediate insights into equipment health, allowing them to identify potential issues before they escalate into unplanned downtime.

2. Predictive maintenance: Digital twins, combined with machine learning (ML)-based analytics, are revolutionising predictive maintenance by enabling real-time monitoring, failure prediction, and optimised maintenance planning. These technologies create virtual replicas of physical assets, continuously collecting and analysing data to identify patterns, forecast failures, and provide insights for proactive maintenance. ML models are trained on historical data to predict equipment failures and recommend maintenance actions.

3. Improved maintenance processes: Digital systems help automate the scheduling of maintenance tasks, ensuring that equipment undergoes regular inspections and repairs. Platforms like CMMS (Computerised Maintenance Management Systems) streamline maintenance workflows, making it easier to track, record, and analyse maintenance activities. Centralised dashboards and mobile accessibility keep all team members informed and facilitate better communication and collaboration.

4. Reduced costs and improved efficiency: Preventive or proactive maintenance reduces the need for emergency repairs and costly downtime. Digital systems also help optimise resource allocation, ensuring that maintenance teams are deployed efficiently. By preventing failures and optimising maintenance schedules, digital technologies help extend the lifespan of equipment.

Planned maintenance schedules, aided by digital technologies, significantly improve Overall Equipment Effectiveness (OEE) by increasing equipment availability, improving performance, and maintaining quality. By proactively scheduling maintenance tasks, companies can minimise unplanned downtime, optimise machine performance, and reduce the risk of equipment failure, all of which contribute to a higher OEE score.

By planning maintenance in advance, companies can allocate resources (labour, materials, and spare parts) more efficiently, reducing costs and improving productivity. OEE data can further be analysed and used to identify areas for improvement in maintenance schedules, optimising resource allocation and maximising equipment uptime.

The case for smart maintenance investments

In today’s high-stakes industrial environment, unplanned downtime is among the costliest risks a company can face. Whether in manufacturing, oil & gas, or utilities, a single hour of unexpected downtime can cost thousands—sometimes even millions—of dollars. Against this backdrop, smart maintenance technologies—such as predictive analytics, IoT-enabled monitoring, and AI-driven diagnostics—offer not just reliability but a compelling return on investment (RoI).

Traditional reactive or time-based maintenance strategies are no longer sufficient. They often lead to over-maintenance, premature part replacements, or, worse, catastrophic failures. In contrast, smart maintenance leverages real-time data to predict and prevent equipment failures before they occur. This shift dramatically reduces unplanned downtime and allows for more efficient allocation of maintenance resources.

Studies have shown that predictive maintenance can reduce maintenance costs by 20-30%, eliminate breakdowns by up to 70%, and cut downtime by up to 50%. For example, a mid-sized automotive plant that typically loses $20,000 per hour of downtime can save hundreds of thousands annually by preempting just a few hours of unexpected failure. Beyond direct savings, smart maintenance also enhances asset life, improves safety, ensures compliance, and supports sustainability goals by minimizing energy waste and material loss.

The upfront investment in smart maintenance—sensors, analytics software, cloud infrastructure—can be substantial, but the RoI is both measurable and fast. Many organisations report payback periods of less than 12 months, particularly in asset-intensive sectors. Furthermore, with scalable and modular solutions now available, even small and medium enterprises can begin with pilot programs and scale up as savings are realized. A recent Siemens news release featuring Sachsenmilch Leppersdorf GmbH, the company operating one of the most modern milk processing plants in Europe, illustrates the efficacy of AI-based predictive maintenance integrated with SAP Plant Maintenance (SAP PM). This pilot with Siemens Senseye Predictive Maintenance has already achieved significant cost savings by reducing unplanned downtime.

Smart maintenance is not merely a technical upgrade; it's a strategic investment. It transforms maintenance from a cost center into a source of competitive advantage—driving uptime, productivity, and long-term operational efficiency. When viewed through the lens of RoI, the question isn't whether to invest in smart maintenance, but how soon it can be implemented to safeguard profitability and resilience.

Conclusion

In conclusion, unplanned downtime stemming from ineffective maintenance practices represents a critical vulnerability in industrial operations. From lost productivity and damaged equipment to safety hazards and reputational harm, the ripple effects are extensive and costly. This article has explored how reactive approaches, lack of predictive insights, and underinvestment in modern maintenance strategies contribute to avoidable disruptions.

The scenario is far from bleak, though. In fact, MaintainX, a leading maintenance and frontline work execution platform, maintains that the industry is learning and adapting to the changed environment. In August 2024, the company released its first annual State of Industrial Maintenance Report, a comprehensive analysis of the challenges, trends and opportunities facing industrial maintenance teams. The global survey captures the sentiments of 1,165 maintenance, repair, and operations (MRO) professionals across a wide range of sectors, facility sizes, and locations. Commenting on the findings in the report, Chris Turlica, CEO and Co-Founder of MaintainX, said, “The decline in the frequency of unplanned downtime highlights that facilities across industries are making positive progress toward improving maintenance, asset reliability, and operational processes." He added, “This report highlights the importance of a proactive maintenance strategy in reducing excessive costs associated with unplanned downtime, improving productivity, and increasing overall efficiency.”

The way forward lies in embracing smart maintenance solutions—leveraging real-time data, analytics, and automation—to shift from a reactive to a proactive maintenance culture. Ultimately, organisations that prioritise maintenance as a strategic function will not only reduce downtime but also gain a competitive edge through enhanced reliability, efficiency, and resilience.

At the very heart of unplanned downtime caused due to maintenance issues is the still widely prevalent culture of reactive maintenance, or the ‘run to failure’ mindset. Companies that follow this approach are still relying on the age-old practice of attending to equipment only after it has failed, which leads to unexpected shutdowns and the consequences that follow. The immediate outcome that results from this is emergency repairs and parts replacements, which is always more expensive than planned maintenance. While equipment failure is a primary cause of unplanned downtime, especially when reactive maintenance is the only strategy employed, there are other factors that contribute to unplanned downtime. These include, apart from poor maintenance practices, operator error, inadequate training and lack of proper planning from inventory to workflows.

Poor asset visibility and tracking is another reason that contributes to unplanned downtime. This refers to a lack of real-time, accurate information about the location, condition, and usage of assets – the machinery, control panels and other ancillary equipment that leads to inefficiencies and increased risk. So when a crisis hits in the form of sudden stoppage of the line, in the absence of precise knowledge of all assets and their location, it becomes difficult to identify, predict, diagnose and then proactively address potential issues with the equipment.

With poor asset visibility, what inevitably follows is lack of predictive maintenance capabilities in maintenance teams, which in turn makes it difficult to anticipate equipment failures. A well maintained plant is usually also well looked after from the maintenance perspective. What is unseen is also ignored until it is too late to pay attention to, delaying necessary repairs, and ultimately increasing the frequency and duration of breakdowns. Without predictive capabilities, maintenance teams are reactive rather than proactive, leading to costly and disruptive downtime. This makes a sound argument in favour of a proactive maintenance strategy. When maintenance teams lack predictive capabilities, they are more likely to react to breakdowns, resulting in increased downtime frequency and duration.

Another significant factor in the series of inefficient maintenance practices is inadequate training and skill gaps in maintenance teams. This results in human errors, hindering effective maintenance, and potentially leading to equipment failures and safety issues. Such skill gaps can result in a variety of problems, including incorrect procedures, missed preventive maintenance tasks, delayed or ineffective troubleshooting, and an overall reduction in the team's ability to maintain equipment reliably. Without the necessary skills to diagnose and fix issues quickly, maintenance teams may spend more time troubleshooting, leading to prolonged downtime while waiting for external help or resources.

It is pertinent to note here that inefficient maintenance practices are not restricted to machinery and equipment. Today almost all industrial plants rely on a variety of software platforms to manage operations, from design and manufacturing to data collection and automation. These include Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), Computerised Maintenance Management Systems (CMMS), Supervisory Control and Data Acquisition (SCADA) systems, and Computer-Aided Design/Manufacturing (CAD/CAM) software. In addition, with increasing digitisation of plants and connected equipment, there are also vulnerabilities like bugs and cyber attacks that afflict the IT infrastructure, which also contributes to unplanned downtime. According to David Flower, Member, Forbes Technology Council, data deluge – the exponential growth of data volume, variety and velocity – is a major downtime driver today. In a signed article on the Forbes portal – The True Cost Of Downtime (And How To Avoid It) – Flower emphasises that legacy tech stacks that weren’t designed to handle such massive workloads can get overwhelmed, buckling under pressure. Hence periodic upgrades and regular maintenance of the IT infrastructure is critical to ensure system reliability and resilience.

In view of the causes mentioned above, what could be the logical thing to do for companies that still rely on reactive maintenance? One of the easiest things to do, to begin with, is to start keeping a meticulous record of the plant from a maintenance perspective. Proper documentation, or CMMS, can help reduce unplanned downtime in industry by centralising all maintenance information, streamlining processes, and facilitating proactive maintenance. By tracking equipment history, scheduling preventive maintenance, and optimising resource allocation, CMMS systems minimise the risk of unexpected breakdowns and improve overall equipment reliability.

Digital twins, combined with ML-based analytics, are revolutionising predictive maintenance. Image by Freepix

Industry spotlights: Real-world downtime losses

One of the worst ever recorded incidents of a maintenance related industrial disaster occurred in the Indian city of Bhopal on the night of December 2-3, 1984. The pesticide plant of Union Carbide, a global MNC, released Methyl isocyanate (MIC) – a highly toxic gas that caused over 3,000 instant deaths in the thickly populated areas around the plant. The immediate cause of the leak was corroded valves and pipelines that remained unrepaired for months. It was exacerbated by multiple factors like the shutting down of the refrigeration system meant to keep MIC cool – and thus less volatile – to save costs; the scrubber system, which neutralises toxic gas leaks, was non-functional at the time; and the flare tower, meant to burn off leaking gases, was out of service due to maintenance neglect. The case dragged on for years in Indian courts. Up to 15,000-20,000 total deaths were attributed over time due to exposure-related illnesses and hundreds of thousands were injured, with long-term health effects. In 1989, Union Carbide reached a settlement with the Indian government by paying a one time settlement amount of $470 million, which was grossly inadequate given the scale of the tragedy. It permanently damaged the credibility of Union Carbide, the company later acquired by Dow Chemicals. The Bhopal plant site was abandoned and remains contaminated to this day. Like the 1986 Challenger Space Shuttle disaster, this too is an extreme example of the terrible consequences that could result from bad maintenance practices.

Presented below are a few more cases, prominent examples from three leading industry segments, including those related to poor maintenance of IT infrastructure:

Oil & Gas/Chemical

BP Texas City Refinery Explosion (2005): In March 2005, a massive explosion occurred at BP's Texas City refinery, later attributed to the failure of critical safety and maintenance procedures. A raffinate splitter tower was overfilled, and a blowdown drum vented flammable liquid, which ignited possibly to a vehicle engine running in the vicinity. The cause was determined as deferred maintenance, outdated equipment, and ignored warnings. Inadequate inspection and safety checks allowed systemic problems to build up. The impact was severe – 15 people killed, more than 180 injured. Operations shut down, and BP faced over $1.5 billion in fines, compensation, and upgrades. This is considered one of the worst (and costliest) industrial accidents in the US.

BASF Ludwigshafen Explosion (2016): An explosion and fire occurred during routine maintenance work on a pipeline system at BASF’s main plant in Ludwigshafen, Germany. It was caused when some contract workers accidentally cut the wrong pipeline, which carried flammable materials. It was later found out that there was a lack of proper identification, communication, and risk mitigation during maintenance at the site. It resulted in the death of 5, including four firefighters, and 44 others were injured. BASF had to shut down multiple production facilities, affecting global supply chains. Financial loss ran into hundreds of millions of euros.

Shell Moerdijk Plant Outage (2014): A fire and explosion occurred at Shell's chemical plant in Moerdijk, Netherlands, due to failed maintenance on a heat exchanger. The cause was later identified as a corroded pipe that went unnoticed during maintenance checks, leading to a leak of flammable gases that ignited. As a result, the operations were halted for months, and Shell faced €200+ million in losses. Production of propylene oxide and styrene monomer—a critical input for plastics—was severely impacted.

Food Industry

Saputo Dairy UK (2019): In 2019, Saputo Dairy UK (formerly Dairy Crest), a major British cheese producer, experienced a plant shutdown at its Davidstow creamery, one of the UK’s largest cheese manufacturing sites, due to a fault in its ammonia refrigeration system — a critical part of the cooling infrastructure. The leak was traced to a failure in maintenance procedures related to the plant’s aging refrigeration equipment. There were inadequate inspections and delayed replacement of parts that should have been flagged during routine maintenance. The incident forced the partial shutdown of the plant for several days to address the safety and mechanical issues. The company incurred hundreds of thousands of pounds in direct losses, plus reputation damage.

JBS USA (2018): A critical freezer malfunction at a JBS beef processing facility in the US caused significant product losses. The root cause was a neglected component in the cooling system that had not been serviced on schedule. The incident resulted in delayed shipments, product disposal, and lost contracts.

The milk processing plant of Sachsenmilch Leppersdorf GmbH. Image source: Siemens

Automotive Industry

Toyota – Japan Production Shutdown (2023): In August 2023, Toyota had to halt operations at all 14 of its assembly plants in Japan due to a system failure in its parts ordering system. Production was completely stopped for a day across Japan. Approximately 13,000 vehicles were affected by the disruption. The root cause was later traced to insufficient disk space on a server following routine maintenance, which prevented the system from processing parts orders. Toyota operates on a just-in-time (JIT) manufacturing model. Even minor disruptions can cascade into major delays. The incident highlighted how IT infrastructure vulnerabilities—not just physical machinery breakdowns—can severely affect operations.

Nissan UK – Production Halt Due to IT Maintenance Failure (2017): In October 2017, Nissan’s Sunderland plant in the UK—the company’s largest manufacturing site in Europe—suffered unplanned downtime due to a failed IT system upgrade during scheduled maintenance. The plant was forced to halt production for nearly two days. The Sunderland facility produces over 500,000 vehicles per year, so even a short disruption had significant output and revenue implications. The failure occurred after a system maintenance upgrade did not go as planned, affecting the plant's ability to manage just-in-time supply chain operations.

Ford – Rouge Plant Explosion (2000): While older, this case underscores how maintenance neglect can have catastrophic effects. An explosion at Ford’s Rouge power plant in Michigan, caused by accumulated dust in a boiler (a maintenance oversight), led to 6 fatalities and 14 injuries. It shut down vehicle production across multiple plants due to loss of power.

These cases illustrate the importance of rigorous safety and facility maintenance practices to avoid both human and operational losses in industrial plants. The chemical and oil & gas industries are particularly sensitive to unplanned downtime, where even brief disruptions can lead to huge financial losses, safety risks, and environmental hazards. Food plants rely heavily on refrigeration and hygienic systems, which are maintenance-sensitive. A small leak or breakdown can lead to product spoilage, compliance violations, and recalls. The automotive industry, traditionally one of the most automated, is today more susceptible to IT related snafus or cyber attacks and needs robust maintenance and protection of the IT system.

The digital divide: Leaders vs. Laggards in maintenance

Technology today offers various tools that can address the issues listed above; factors that are responsible for poor maintenance practices. The good thing is many companies are adopting them to their advantage. The bad thing, as noted in the ABB Report quoted at the beginning of this article, is that 21% of the 3,215 respondents still conduct run-to-fail or ‘reactive maintenance’. Worse, they continue with the conventional practice not because of ignorance but in spite of being aware of the solutions available to address the problem.

Digital technologies, particularly those related to predictive maintenance and asset management, significantly reduce unplanned downtime due to poor maintenance practices by providing real-time data, enabling proactive maintenance, and improving overall maintenance efficiency.

This is achieved in the following ways:

1. Real-time data and monitoring with IoT sensors: Industrial Internet of Things (IoT) sensors collect data on equipment performance, temperature, vibration, and other relevant parameters. Advanced analytics algorithms analyse sensor data to identify patterns, anomalies, and potential failures. This real-time data provides maintenance teams with immediate insights into equipment health, allowing them to identify potential issues before they escalate into unplanned downtime.

2. Predictive maintenance: Digital twins, combined with machine learning (ML)-based analytics, are revolutionising predictive maintenance by enabling real-time monitoring, failure prediction, and optimised maintenance planning. These technologies create virtual replicas of physical assets, continuously collecting and analysing data to identify patterns, forecast failures, and provide insights for proactive maintenance. ML models are trained on historical data to predict equipment failures and recommend maintenance actions.

3. Improved maintenance processes: Digital systems help automate the scheduling of maintenance tasks, ensuring that equipment undergoes regular inspections and repairs. Platforms like CMMS (Computerised Maintenance Management Systems) streamline maintenance workflows, making it easier to track, record, and analyse maintenance activities. Centralised dashboards and mobile accessibility keep all team members informed and facilitate better communication and collaboration.

4. Reduced costs and improved efficiency: Preventive or proactive maintenance reduces the need for emergency repairs and costly downtime. Digital systems also help optimise resource allocation, ensuring that maintenance teams are deployed efficiently. By preventing failures and optimising maintenance schedules, digital technologies help extend the lifespan of equipment.

Planned maintenance schedules, aided by digital technologies, significantly improve Overall Equipment Effectiveness (OEE) by increasing equipment availability, improving performance, and maintaining quality. By proactively scheduling maintenance tasks, companies can minimise unplanned downtime, optimise machine performance, and reduce the risk of equipment failure, all of which contribute to a higher OEE score.

By planning maintenance in advance, companies can allocate resources (labour, materials, and spare parts) more efficiently, reducing costs and improving productivity. OEE data can further be analysed and used to identify areas for improvement in maintenance schedules, optimising resource allocation and maximising equipment uptime.

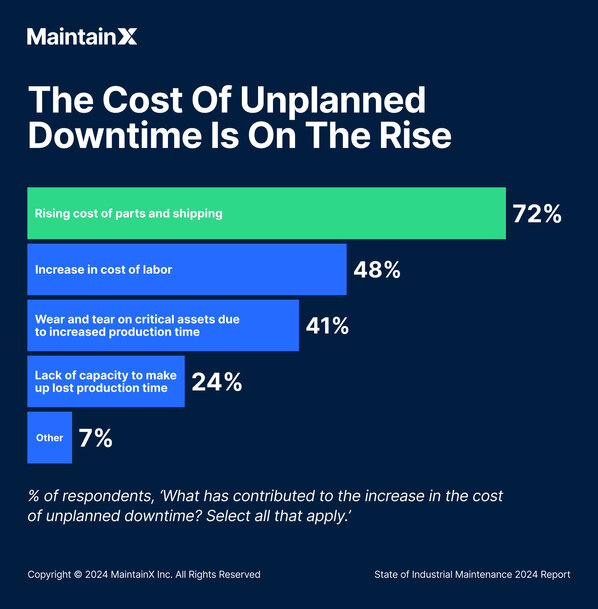

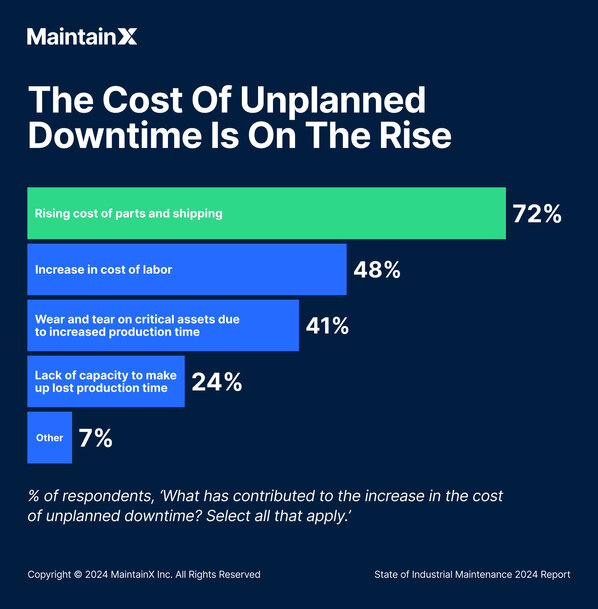

The rising cost of unplanned downtime. Image source: MaintainX

The case for smart maintenance investments

In today’s high-stakes industrial environment, unplanned downtime is among the costliest risks a company can face. Whether in manufacturing, oil & gas, or utilities, a single hour of unexpected downtime can cost thousands—sometimes even millions—of dollars. Against this backdrop, smart maintenance technologies—such as predictive analytics, IoT-enabled monitoring, and AI-driven diagnostics—offer not just reliability but a compelling return on investment (RoI).

Traditional reactive or time-based maintenance strategies are no longer sufficient. They often lead to over-maintenance, premature part replacements, or, worse, catastrophic failures. In contrast, smart maintenance leverages real-time data to predict and prevent equipment failures before they occur. This shift dramatically reduces unplanned downtime and allows for more efficient allocation of maintenance resources.

Studies have shown that predictive maintenance can reduce maintenance costs by 20-30%, eliminate breakdowns by up to 70%, and cut downtime by up to 50%. For example, a mid-sized automotive plant that typically loses $20,000 per hour of downtime can save hundreds of thousands annually by preempting just a few hours of unexpected failure. Beyond direct savings, smart maintenance also enhances asset life, improves safety, ensures compliance, and supports sustainability goals by minimizing energy waste and material loss.

The upfront investment in smart maintenance—sensors, analytics software, cloud infrastructure—can be substantial, but the RoI is both measurable and fast. Many organisations report payback periods of less than 12 months, particularly in asset-intensive sectors. Furthermore, with scalable and modular solutions now available, even small and medium enterprises can begin with pilot programs and scale up as savings are realized. A recent Siemens news release featuring Sachsenmilch Leppersdorf GmbH, the company operating one of the most modern milk processing plants in Europe, illustrates the efficacy of AI-based predictive maintenance integrated with SAP Plant Maintenance (SAP PM). This pilot with Siemens Senseye Predictive Maintenance has already achieved significant cost savings by reducing unplanned downtime.

Smart maintenance is not merely a technical upgrade; it's a strategic investment. It transforms maintenance from a cost center into a source of competitive advantage—driving uptime, productivity, and long-term operational efficiency. When viewed through the lens of RoI, the question isn't whether to invest in smart maintenance, but how soon it can be implemented to safeguard profitability and resilience.

Conclusion

In conclusion, unplanned downtime stemming from ineffective maintenance practices represents a critical vulnerability in industrial operations. From lost productivity and damaged equipment to safety hazards and reputational harm, the ripple effects are extensive and costly. This article has explored how reactive approaches, lack of predictive insights, and underinvestment in modern maintenance strategies contribute to avoidable disruptions.

The scenario is far from bleak, though. In fact, MaintainX, a leading maintenance and frontline work execution platform, maintains that the industry is learning and adapting to the changed environment. In August 2024, the company released its first annual State of Industrial Maintenance Report, a comprehensive analysis of the challenges, trends and opportunities facing industrial maintenance teams. The global survey captures the sentiments of 1,165 maintenance, repair, and operations (MRO) professionals across a wide range of sectors, facility sizes, and locations. Commenting on the findings in the report, Chris Turlica, CEO and Co-Founder of MaintainX, said, “The decline in the frequency of unplanned downtime highlights that facilities across industries are making positive progress toward improving maintenance, asset reliability, and operational processes." He added, “This report highlights the importance of a proactive maintenance strategy in reducing excessive costs associated with unplanned downtime, improving productivity, and increasing overall efficiency.”

The way forward lies in embracing smart maintenance solutions—leveraging real-time data, analytics, and automation—to shift from a reactive to a proactive maintenance culture. Ultimately, organisations that prioritise maintenance as a strategic function will not only reduce downtime but also gain a competitive edge through enhanced reliability, efficiency, and resilience.