www.industry-asia-pacific.com

27

'26

Written on Modified on

Kongsberg Maritime Wins Major Deck Machinery Order

Kongsberg Maritime has signed a contract to deliver a comprehensive deck machinery package for a new-generation 127-metre Floating Wind Construction Vessel being built for Hana Shipping of Korea.

www.kongsberg.com

Kongsberg Maritime has secured a significant contract to equip Hana Shipping’s new 127-metre Floating Wind Construction Vessel (FWCV) with a comprehensive deck machinery suite, underscoring its differentiated capability in supplying advanced handling systems tailored for complex offshore wind operations. The project highlights both the growing demand for specialised equipment in the floating offshore wind segment and Kongsberg’s strategic role in integrating high-performance handling solutions early in vessel design.

Meeting the Demands of Next-Generation Floating Wind Installation

The FWCV, designed by Focal and scheduled for delivery in July 2027, will operate at the Ulsan Floating Wind Farm Construction site approximately 70 kilometres off the coast of Ulsan, South Korea. Its intended roles include anchor handling, towing, cable laying and a range of construction tasks associated with floating wind farms, which require robust and versatile deck handling systems capable of meeting heavy-duty offshore workloads.

Kongsberg’s early engagement in the vessel’s design phase allowed its engineering team to integrate deck machinery systems that are optimised for the vessel’s operational profile. This upfront design involvement aims to ensure that towing, mooring and installation tasks can be executed safely and efficiently, with systems that are precisely matched to structural and functional requirements rather than retrofitted later in the build process.

Scope of Delivery: High-Capacity Winches and Intelligent Controls

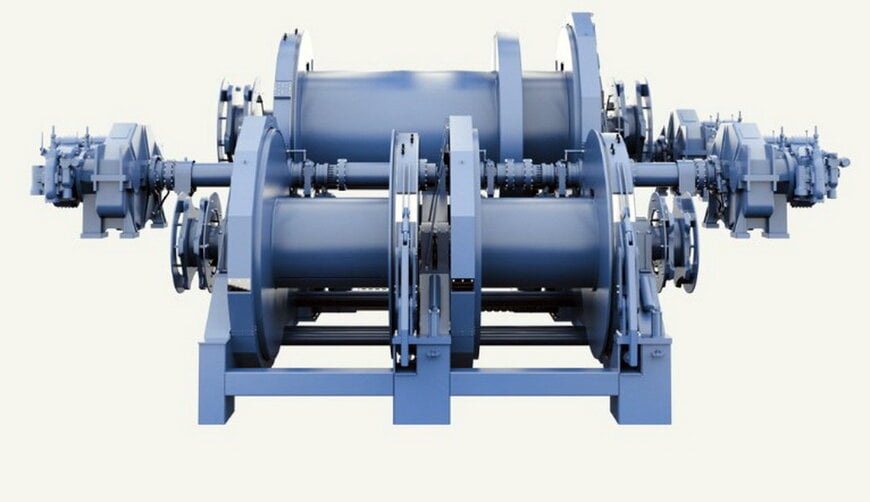

Central to the contract is a state-of-the-art deck machineries package anchored by a 500-tonne main towing and anchor-handling winch system with three drums. Complementing this primary system, Kongsberg will supply secondary winches for rope installation, a rope tensioner system, tugger winches, and an active heave-compensated working winch. The full suite is controlled through the company’s Towcon X8 control system, which consolidates operational oversight and enhances precision during complex handling tasks. All winches use Kongsberg’s proprietary low-pressure hydraulic motors, manufactured in Norway, ensuring high reliability and serviceability. Mechanical components for the main winches are supplied by long-term industrial partner IP Huse.

Innovative Systems for Large Anchor Handling and Mooring Tasks

In addition to conventional winch systems, the contract introduces specialized equipment developed for large anchor handling and mooring operations. The next-generation Shark Jaw system can handle chain sizes up to 220 mm and features remotely adjustable inserts, which enhance both safety and operational flexibility for handling heavy chain under variable offshore conditions. The AH100 rail cranes extend load capacity and reach, featuring dual-arm configurations with interchangeable tooling designed to support a variety of project-specific tasks on a construction vessel. These innovations reflect Kongsberg’s focus on tailored solutions that address the specific challenges of floating wind installation versus more generic offshore applications.

Differentiation in a Nascent Market Segment

While the broader deck machinery market includes standard winches and handling equipment for merchant, supply or fishing vessels, the requirements for floating wind construction place higher demands on performance, integration and operational flexibility. Kongsberg’s combination of early design involvement, advanced control systems and bespoke hardware positions it competitively in this emerging segment, differentiating its offering from providers with more generic offshore handling portfolios.

In summary, the Hana Shipping FWCV contract demonstrates how integrated deck machinery solutions—including high-capacity winches, intelligent controls and innovative handling systems—are critical to enabling the next phase of offshore wind farm installation, particularly in floating applications where heavy and complex operations are routine.

www.kongsberg.com