www.industry-asia-pacific.com

24

'17

Written on Modified on

Ten times more service life for linear guides in robotic welding applications

A manufacturer of sheet metal assemblies recently sought a solution to short lifespan issues with the drive and guide elements on its automated welding systems. In fact, the linear guides for a robotic welding gun on one particular production line had to be replaced every two or three months. Due to the cost of replacement parts and maintenance time, as well as equipment downtime, the company asked NSK to investigate and provide a proposal to address the problem.

NSK discovered that weld spatter and fumes were adversely impacting the operating life of the guide elements. The company therefore suggested replacing the existing guides with its NH series linear guides in combination with protectors and K1 maintenance-free lubrication units.

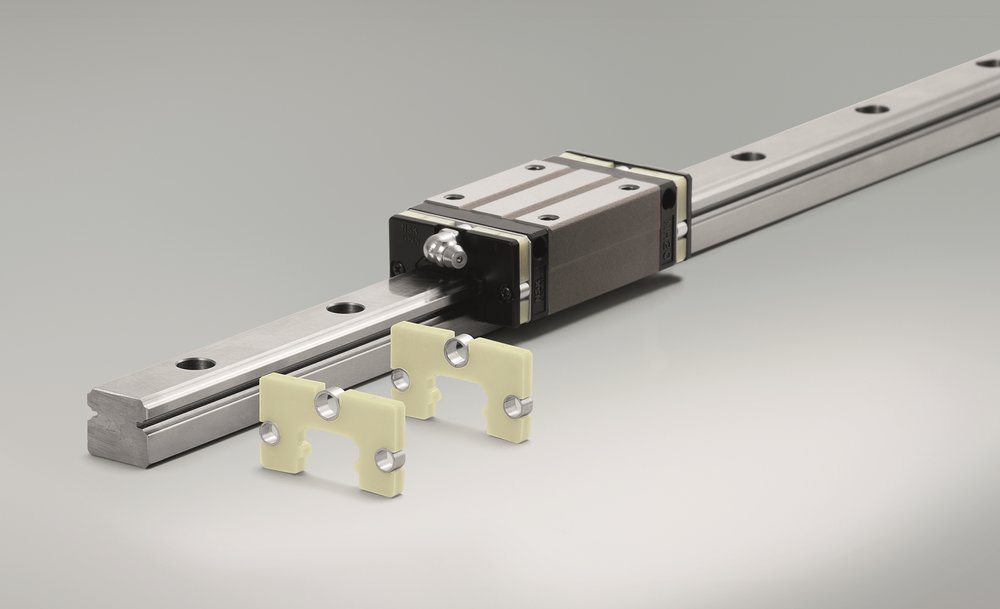

Capable of providing long-lifetime performance in automated welding applications, the protectors effectively shield the sealing lip and prevent contamination from reaching the guide interior. An effect of the use of protectors is increased contact pressure between the rail surface and the seal. In this application, NSK also recommended the use of its K1 lubrication units, which allow the sealing lip to move at low friction over a film of oil. The K1 comprises a synthetic base material that holds the lubricant in its pores and extrudes it continuously, thus delivering maintenance-free operation.

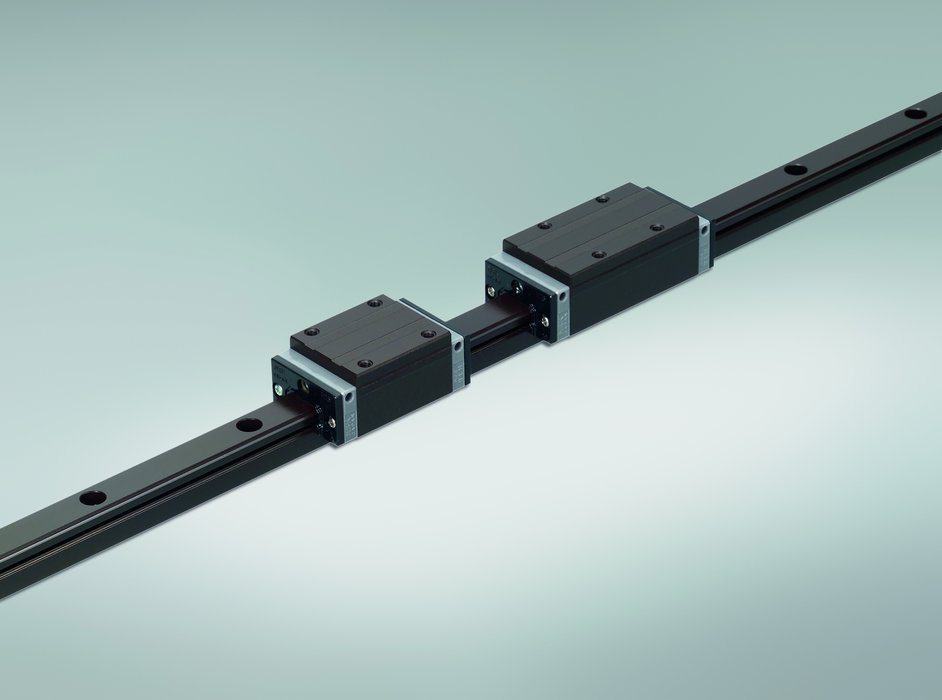

For additional protection, the surfaces of the linear guides were plated with black chrome to prevent the permanent adhesion of weld spatter. Spatter adheres only lightly to the plated surfaces and gets dislodged when contact is made with a protector.

NSK’s NH series linear guide solution has solved the customer’s problem to its complete satisfaction. The C-type weld guns have been in operation for over three years without any failures. To date, this means that service life has been multiplied by a factor of 10.

-Image2.jpeg – NSK’s K1 lubrication units and protectors significantly increase the service life of linear guides

-Image3.jpeg – Black chrome plating helps prevent weld spatter from becoming permanently attached to the linear guides