www.industry-asia-pacific.com

13

'17

Written on Modified on

High Fin Ratio Extrusions

Aavid has developed a new range of heatsinks in extruded aluminium to satisfy the growing need amongst our customers for improved performance and efficiency. High Fin Ratio extrusions overcome the limits of findensity in traditional flat-back extrusions, resulting in an increase in performance when operating in forced convection.

What are the advantages for our customers?

An average increase of 20% in thermal performance based on the same size.

In fact, this result emerges from simulations made comparing the performance of anultra-performance High Fin Ratio extrusion in forced convection with a standard extrusion of the same length and height.

It is important to underline that these extrusions are to be used exclusively in forced convection.

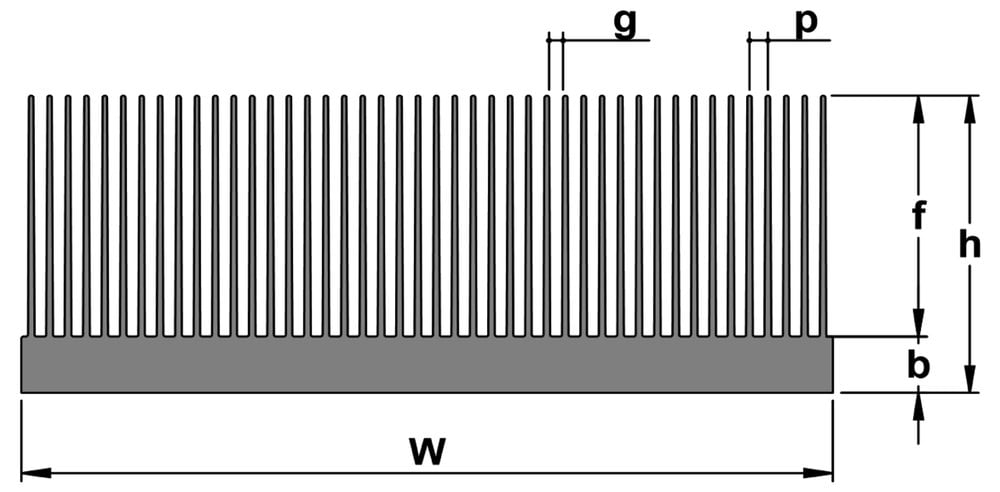

Here are some of the thermal characteristics of two of the profiles currently available:

HFR170

W = 189.4 mm

h = 74.0 mm

p = 4.3 mm

Rth,f = 0.084 °C/W

Peso 16.4kg/m

HFR380

W = 393.6 mm

h = 80.7 mm

p = 5.8 mm

Rth,f = 0.050 °C/W

Peso 34.1 kg/m

For more detailed information, download the brochure here: http://www.aavid.eu/sites/default/files/literature/High-Fin-Ratio-Extrusions.pdf

Reduction in weight and cost.

Compared with heatsinks assembled using bonding material of whatever nature and independently of the type of fin, an extrusion guarantees continuity in thermal conduction. Furthermore, the weight reduction can be significant as superfluous fins are eliminated. Performance is similar when using brazing technology but savings can be madeby eliminating this more costly production process. In all the cases mentioned above the extrusion process is however always more economical.

All-round customer support.

Choose between the standard profiles in stock and purchasing your sample for testing purposes through our Online Store and you will receive your sample for testing purposes in less than 48 hours. If you need a personalized solution to respondto your requirements ask our Design Centre to optimize the performance based on your specifications.