www.industry-asia-pacific.com

11

'25

Written on Modified on

DMG MORI presents innovative, holistic manufacturing solutions for Machining Transformation

At CIMT 2025, DMG MORI will showcase CNC machining innovations with automation, DX, GX, and integration, featuring machines and solutions.

en.dmgmori.com

Local Production Machines Live: ALC 2500, DMU 50c, DMU 75c monoBLOCK

Local Production: Strengthening local markets

Tianjin and Pinghu plants are important presences in China for DMG MORI. Both two plants keep consistent standards with group headquarters in many aspects, including site selection, plant construction, equipment selection, supplier system, personnel selection, training and operation. Thanks to short transportation routes and local production, we can guarantee particularly short delivery times, protect the environment and strengthen the regional economy. This also enables us to contact and serve customers in close proximity promptly, receive constructive suggestions from local customers, continuously improve products, step further to meet local customers’ needs.

The DMU 75c monoBLOCK with PH Cell and DMU 50c exhibited in 2025 CIMT are manufactured by Pinghu factory, which is a highly automated and fully digitized world-class modern factory. Now at 2025 CIMT, both machines are available with ultra-fast delivery, DMG MORI provides customers with real one-stop solutions from design consultation to customizing solutions, product supply, and engineering services.

NLX 2500|700: DMG MORI has embedded the NLX 2500|700 2. Generation in the Machining Transformation (MX) concept.

NLX 2500|700 2nd generation - the new turning center of the next generation

As the successor model to the successful turning center, the NLX 2500|700 2nd generation includes far-reaching optimizations in machine structure, control and various functionalities. DMG MORI has taken into account the requirements of today's markets and embedded the new model in the Machining Transformation (MX) concept. Process integration, automation, digital transformation (DX) and green transformation (GX) are the main pillars of this concept with which DMG MORI is shaping the future of manufacturing. The NLX 2500|700 2nd generation offers users with different requirements maximum flexibility and reliability in universal turning.

The core characteristics of the high-performance NLX series - its stability and the associated precision - have been further improved. The aim is to reduce throughput times and increase machining quality. With these measures and the adaptation of high-torque turnMASTER spindles on the left and right, the NLX 2500|700 2nd generation will continue to set standards in the productive heavy-duty machining of demanding workpieces with a diameter of up to ø 366 mm and a turning length of 705 mm. The maximum bar capacity for operation with bar feeders has been increased to ø 105 mm on both spindles, compared to ø 80 mm on the previous generation. The travel distances are 260 mm in the X-axis and 795 mm in the Z-axis. A travel path of 120 mm (± 60 mm) in the Y-axis for off-center milling, drilling and other process steps with driven tools offers maximum flexibility. Measurements can be carried out at various positions during machining, allowing the user a high degree of process integration.

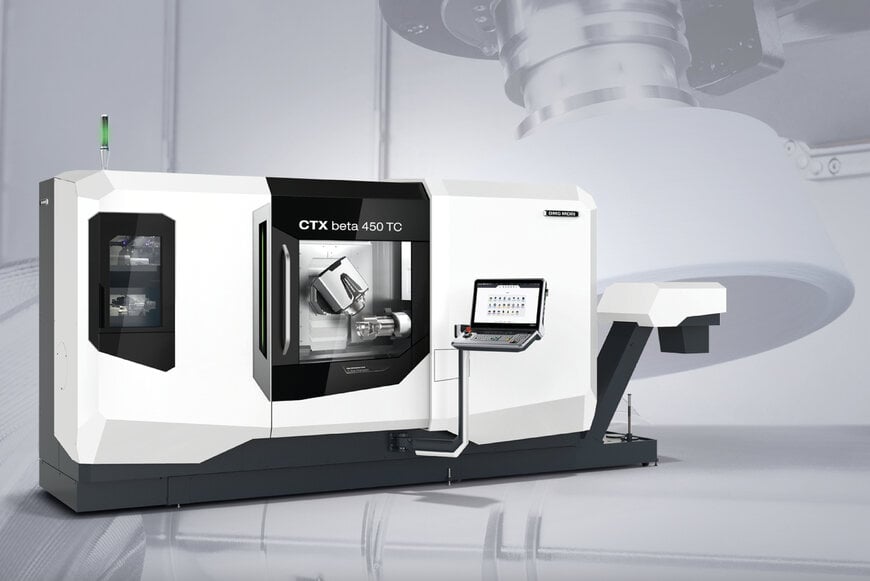

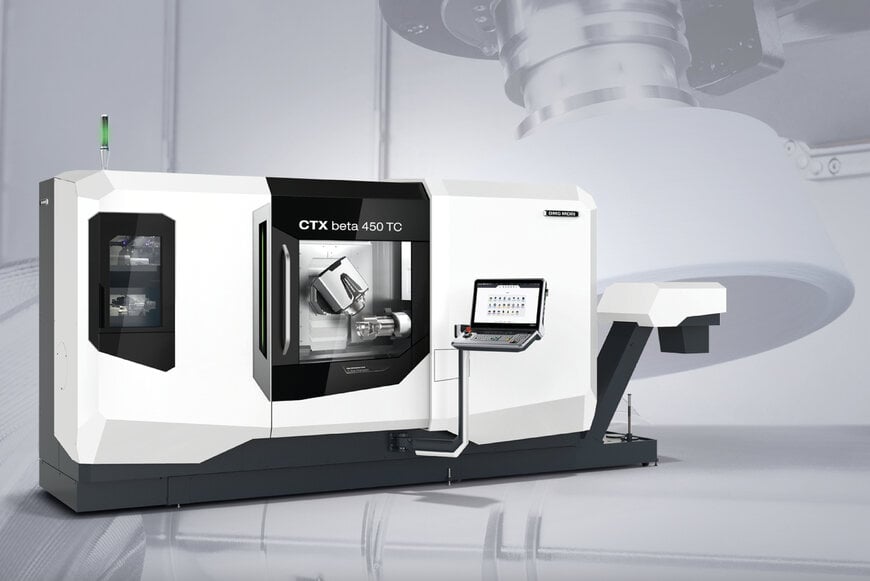

With a footprint of just 10 m², the CTX beta 450 TC marks the new entry into DMG MORI's series of high-tech turning/milling centers.

Better equipped with the CTX beta 450 TC

6-sided complete machining on turn-mill centers of the CTX TC series has been a tradition at DMG MORI for many years. The new CTX beta 450 TC impressively continues this success story. Ease of operation, efficiency, technology and automation were at the heart of its development. This makes the new turning/milling center a perfect example of the Machining Transformation (MX) and its four pillars of Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX). DMG MORI is using it to shape the future of manufacturing.

For example, the new control generation with CELOS X enables simple, app-based end-to-end workflows and offers the operator innovations such as OP Workbench for easier and more structured NC programming. 5-axis simultaneous machining, 5-in-1 technology integration and 6-sided complete machining also ensure precision, flexibility and productivity. With a footprint of just 10 m², the CTX beta 450 TC marks the new entry into the CTX TC series. The work area offers space for workpieces with a diameter of up to ø 400 mm and a length of up to 1,100 mm. The bar capacity is ø 76 mm or optionally ø 102 mm for both the main spindle and the counter spindle. At the heart of the new model is the compactMASTER turn-mill spindle with a speed of 15,000 rpm as standard and optionally 20,000 rpm. The main and counter spindles achieve speeds of up to 5,000 rpm and a maximum torque of 720 Nm. The high performance of the CTX beta 450 TC is also reflected in rapid traverse speeds of up to 50 m/min.

LASERTEC 50 PrecisionTool Femto - maximum precision in micromachining

With a positioning accuracy of a few micrometers, the 5-axis LASERTEC 50 PrecisionTool Femto is an efficient solution for the precise production of complex micro-tools. At the heart of this process is the 20 watt femto laser. Thanks to ultra-short pulses, it enables minimal material removal, allowing the machine to achieve surface accuracies of less than Ra 0.1 µm. It is designed for tool diameters of up to ø 0.3 mm. Thanks to the combination of powerful femtosecond technology and 5-axis simultaneous machining, the LASERTEC 50 PrecisionTool Femto enables highly economical complete machining in competitive throughput times. The optional PH 50 pallet handling system enables even more productive production, even in unmanned shifts.

www.dmgmori.com

Local Production: Strengthening local markets

Tianjin and Pinghu plants are important presences in China for DMG MORI. Both two plants keep consistent standards with group headquarters in many aspects, including site selection, plant construction, equipment selection, supplier system, personnel selection, training and operation. Thanks to short transportation routes and local production, we can guarantee particularly short delivery times, protect the environment and strengthen the regional economy. This also enables us to contact and serve customers in close proximity promptly, receive constructive suggestions from local customers, continuously improve products, step further to meet local customers’ needs.

The DMU 75c monoBLOCK with PH Cell and DMU 50c exhibited in 2025 CIMT are manufactured by Pinghu factory, which is a highly automated and fully digitized world-class modern factory. Now at 2025 CIMT, both machines are available with ultra-fast delivery, DMG MORI provides customers with real one-stop solutions from design consultation to customizing solutions, product supply, and engineering services.

NLX 2500|700: DMG MORI has embedded the NLX 2500|700 2. Generation in the Machining Transformation (MX) concept.

NLX 2500|700 2nd generation - the new turning center of the next generation

As the successor model to the successful turning center, the NLX 2500|700 2nd generation includes far-reaching optimizations in machine structure, control and various functionalities. DMG MORI has taken into account the requirements of today's markets and embedded the new model in the Machining Transformation (MX) concept. Process integration, automation, digital transformation (DX) and green transformation (GX) are the main pillars of this concept with which DMG MORI is shaping the future of manufacturing. The NLX 2500|700 2nd generation offers users with different requirements maximum flexibility and reliability in universal turning.

The core characteristics of the high-performance NLX series - its stability and the associated precision - have been further improved. The aim is to reduce throughput times and increase machining quality. With these measures and the adaptation of high-torque turnMASTER spindles on the left and right, the NLX 2500|700 2nd generation will continue to set standards in the productive heavy-duty machining of demanding workpieces with a diameter of up to ø 366 mm and a turning length of 705 mm. The maximum bar capacity for operation with bar feeders has been increased to ø 105 mm on both spindles, compared to ø 80 mm on the previous generation. The travel distances are 260 mm in the X-axis and 795 mm in the Z-axis. A travel path of 120 mm (± 60 mm) in the Y-axis for off-center milling, drilling and other process steps with driven tools offers maximum flexibility. Measurements can be carried out at various positions during machining, allowing the user a high degree of process integration.

With a footprint of just 10 m², the CTX beta 450 TC marks the new entry into DMG MORI's series of high-tech turning/milling centers.

Better equipped with the CTX beta 450 TC

6-sided complete machining on turn-mill centers of the CTX TC series has been a tradition at DMG MORI for many years. The new CTX beta 450 TC impressively continues this success story. Ease of operation, efficiency, technology and automation were at the heart of its development. This makes the new turning/milling center a perfect example of the Machining Transformation (MX) and its four pillars of Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX). DMG MORI is using it to shape the future of manufacturing.

For example, the new control generation with CELOS X enables simple, app-based end-to-end workflows and offers the operator innovations such as OP Workbench for easier and more structured NC programming. 5-axis simultaneous machining, 5-in-1 technology integration and 6-sided complete machining also ensure precision, flexibility and productivity. With a footprint of just 10 m², the CTX beta 450 TC marks the new entry into the CTX TC series. The work area offers space for workpieces with a diameter of up to ø 400 mm and a length of up to 1,100 mm. The bar capacity is ø 76 mm or optionally ø 102 mm for both the main spindle and the counter spindle. At the heart of the new model is the compactMASTER turn-mill spindle with a speed of 15,000 rpm as standard and optionally 20,000 rpm. The main and counter spindles achieve speeds of up to 5,000 rpm and a maximum torque of 720 Nm. The high performance of the CTX beta 450 TC is also reflected in rapid traverse speeds of up to 50 m/min.

LASERTEC 50 PrecisionTool Femto - maximum precision in micromachining

With a positioning accuracy of a few micrometers, the 5-axis LASERTEC 50 PrecisionTool Femto is an efficient solution for the precise production of complex micro-tools. At the heart of this process is the 20 watt femto laser. Thanks to ultra-short pulses, it enables minimal material removal, allowing the machine to achieve surface accuracies of less than Ra 0.1 µm. It is designed for tool diameters of up to ø 0.3 mm. Thanks to the combination of powerful femtosecond technology and 5-axis simultaneous machining, the LASERTEC 50 PrecisionTool Femto enables highly economical complete machining in competitive throughput times. The optional PH 50 pallet handling system enables even more productive production, even in unmanned shifts.

www.dmgmori.com