www.industry-asia-pacific.com

26

'16

Written on Modified on

Specialized Drives for Driverless Transport Systems

Servo drives that park cars

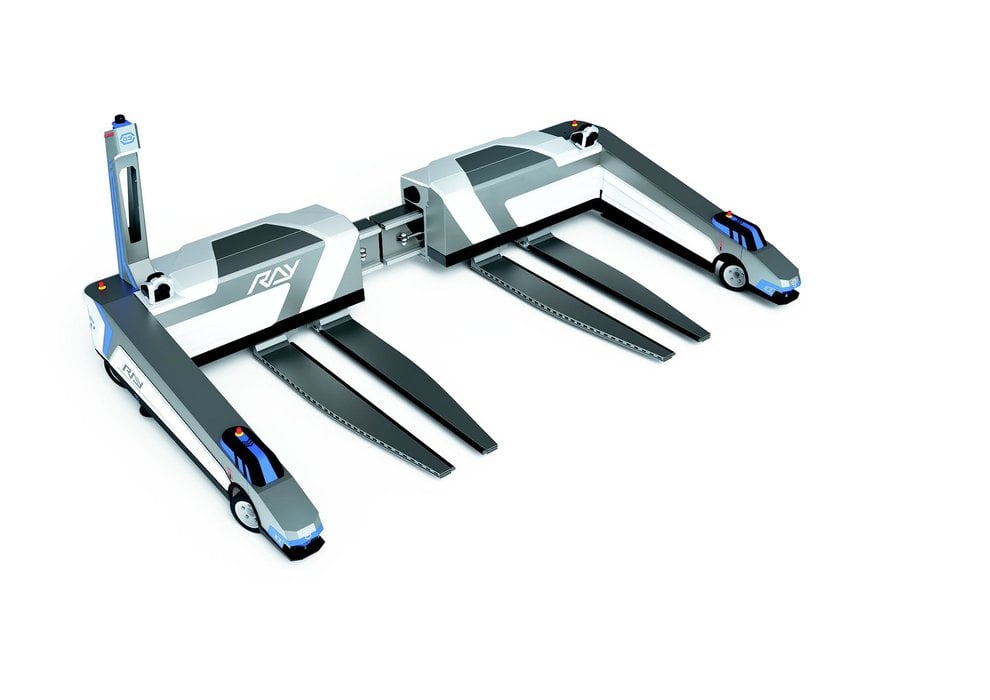

A solution using an autonomous vehicle has been introduced to reduce parking problems in major cities. The two main drives as well as the servo controller are critical components of the system. Above all, it is essential that none of the cars, whether Volkswagens or Ferraris, get damaged in the process. Elmo’s servo drives were put up to the task of driving the robot, answering the challenges of smooth operation, size, reliability, safety, and service quality.

The number of cars in Germany has continued to grow and reached a new peak in 2015 according to data from the Federal Motor Transport Authority. At the beginning of the year, there were 44.4 million cars registered in Germany. The city streets are jammed and sooner or later all cars will have to find somewhere to park. The spiralling cost of land, increase land requirements, and aging multi-storey car parks combine to make the provision of parking space an increasing challenge. At the same time, users parking space users are expect increased convenience and ease of use.

To meet these challenges, Serva Transport Systems has developed a smart solution, under the theme of "We park for you!". The solution not only can integrate easily into existing parking infrastructures but also offers economic advantages in the context of projects that are in their planning stage. The Ray automated parking system was designed after several years of research and development. Based on the idea of a robotic system similar to a fork lift truck, it takes over the job of parking the cars. With car models that are getting bigger and bigger, it has become harder for customers to manoeuvre their vehicle in confined spaces and narrow parking aisles. The Ray system is fast, convenient and makes efficient use of the limited parking space available. The system has been in official operation for quite some time. At Dusseldorf Airport for example, 249 parking spaces have been in service since mid-2014. Other applications for the parking robot are mainly intended for finished car logistics, such as the Audi factories in Ingolstadt.

How the system works

With the Serva Transport Systems automated parking system, drivers hand over their car at a transfer station in the parking garage. The car is then locked and its dimensions are lased measured. Based on this data, the best available parking space in the parking garage is determined. The remainder of the parking operation is handled by the Ray robot. After the driver has left the transfer station, the driverless transport vehicle lifts the car, makes a test measurement and parks the car in the previously determined space in the parking garage, explains Daniel Boyé, Sales Director of Serva Transport Systems. The parking robot automatically adapts itself to the dimensions of the car and carries it safely to its destination. Because the robot does not need rails, it can drive on individual routes. No building modifications or additional fixtures were needed for this up-to-date parking method. As a result, parking space useage was 60% more efficient

Smooth and safe operation

As a young company, Serva Transport Systems’ short history goes back only to the year 2010. From the beginning, growth has been continuous. Serva’s customer portfolio now includes a large number of well-known companies in the automotive industry. The drive technology is the component at the heart of the driverless transport system. The two main drives at the rear of the chassis are of particular importance because the system transports expensive cars that must not be damaged while they are being parked. Because the parking robot has to manoeuvre in very narrow spaces, there is not much space available for the drives. The servo drives have to be small in size and light in weight, but nevertheless must be powerful because some of the vehicles to be transported are very heavy. To ensure smooth travel as well as accurate and damage free parking, the company chose Gold Drum servo drives made by Israeli company Elmo Motion Control. The 150 A / 48 V version is used in both main drives which provide fast control for smooth driving. Because the drives do not require much space, the compact and powerful servo controls, weighing only 700g and with dimensions of 95x 72 xs134 mm (WxHxD) are ideal for applications in small spaces.

Another feature of the Gold Drum is that it can be used in single axis mode as well as multi-axis operation. In this model range, it outputs 15 kW of continuous power with a peak performance of 20 kW. The source voltage can range from as little as 14 up to 100 VDC. The Gold Drum also provides a certified EtherCAT or CANopen connection for real time applications, as well as certified STO safety functionality. The servo controller includes all the features needed for the dynamics, precision and communication of the system. It is thus able to satisfy even highly complex requirements.

Service to match the product

Hardware is not the only key deciding criteria in the selection of the servo controller. Quality of service, before, during and after the purchase decision, was also very important for the parking system manufacturer. With Elmo Motion Control ,Serva found a supplier for whom product quality and service go hand in hand. 'This philosophy fits exactly with our own", said Leopold Meirer, CEO of Serva Transport Systems.

Specific solutions

The driverless transport system is suitable for car manufacturers, car rentals, logistics companies or car park facilities. It saves space, it is simple to install, and can be implemented flexibly. As a partner, Elmo Motion Control meets the highest demands that robotic parking systems put on the drive electronics. The servo controllers are robust and ensure that the robot is driven smoothly.

Author: Thomas Herold, Customer consultant, PR-Agency in Ubstadt-Weiher