www.industry-asia-pacific.com

13

'16

Written on Modified on

De Dietrich Process Systems is launching a new external protection of glass-lined parts.

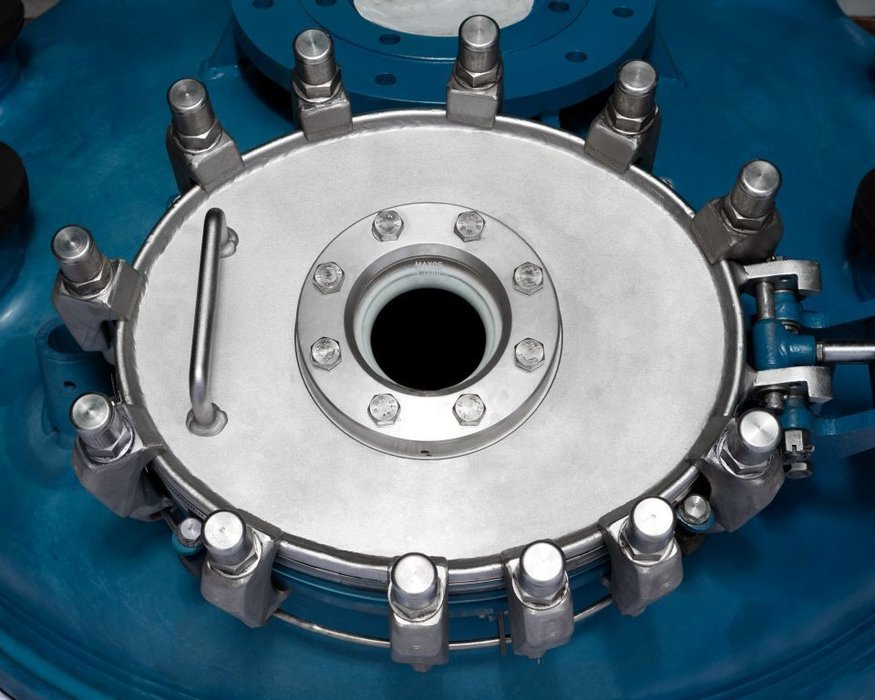

To address the problems of its customers, particularly in pharmaceutical and fine chemicals, sensitive to the risk of contamination of their products by paint chips, De Dietrich Process Systems has developed a new exterior nickel coating for glass-lined parts.

The external protection of process equipment (reactors, piping, etc.) in glass-lined steel is traditionally provided by the paint. These paints have excellent corrosion resistance but may in places be subject to high mechanical stress, and flake.

The GMP (Good Manufacturing Practices) standards of the pharmaceutical industry prohibit the fact that a paint flake can contaminate the final product.

To address this risk, De Dietrich Process Systems has developed a nickel coating solution that provides corrosion protection comparable to painting, while eliminating the risk of chipping.

Indeed, nickel coating has outstanding properties:

• Bonds perfectly with the base material

• Impact resistant

• Easy to clean thanks to a specific surface preparation

• Makes it possible to apply homogenous surface coating to components with complex geometries

For any further information (price, delivery time…), please contact:

De Dietrich Process Systems

30 Grand Rue, 67110 Zinswiller

France

Phone: +33 3 88 53 23 00

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.dedietrich.com