www.industry-asia-pacific.com

03

'24

Written on Modified on

GF Piping Systems supplies 5,000 valves for revolutionized bioplastics production in China

Swiss flow solutions provider GF Piping Systems provided a valve solution for Tianjin-based Oumingzhuang Biological Technology, enhancing efficiency and reducing wastewater discharge for the construction of a new ion exchanger generation.

Lactic acid is a key raw material for bioplastics which can be used for everyday products ranging from bags and cutlery to packaging materials. To meet the growing demand for this organic compound, process equipment specialist OMZ builds ion exchangers capable of turning corn starch into lactic acid. As part of a ten-year partnership, the company relies on GF Piping Systems to provide valves for its highly automated solutions.

With the goal of enabling its customers to reduce their water usage and wastewater discharge, OMZ saw an opportunity in 2020 to expand the volume and efficiency of its 5th generation ion exchanger. In order to achieve this goal, the company required technical solutions that provided a high level of reliability in acidic environments and could be integrated into a modern automation loop.

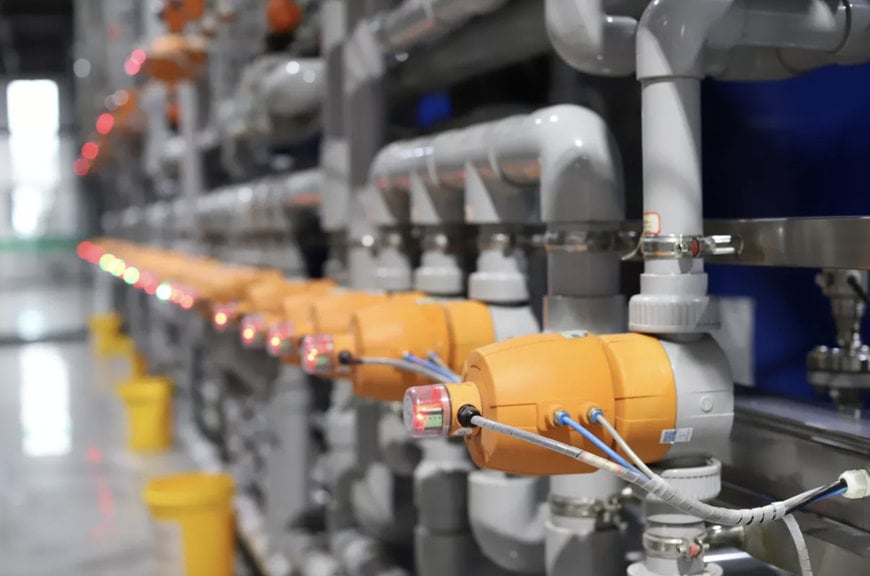

During the project, OMZ and GF Piping Systems installed a total of 5,000 valves across seven parallel ion exchangers. By selecting DN50 valves, it was possible to implement smaller sizes while maintaining an equivalent flow capacity. As a result, OMZ could also downsize the equipment and reduce the overall weight of the system. Once installed, the thermoplastic valves were able to increase efficiency, reduce wastewater discharge by 40%, and improve resin utilization by 30%.

Zhang Tianti, General Manager at OMZ, is pleased with the results of the collaboration: “We have enjoyed a decade-long partnership with GF Piping Systems, whose products and services have been instrumental in our success. GF Piping Systems is a trusted and reliable partner, and we eagerly anticipate continuing our collaboration in areas such as biotechnology fermentation and lithium extraction from salt lakes to further advance sustainable industrial development.”

Wang Yingjie, Senior Sales Manager, Energy Key Account Sales at GF Piping Systems China, adds: “We are committed to strengthening our business impact without forgetting to do so in a sustainable way and contributing to societal and technological progress. Bioplastics made with lactic acid are essential to replace everyday products that are traditionally made of petroleum-based plastics. We are therefore proud to have supplied more than 100,000 valves to OMZ throughout our partnership.”

www.gfps.com