www.industry-asia-pacific.com

24

'16

Written on Modified on

DP Technology Corp. Announces the Release of its Ultimate Machine Tool Solution

Optimize your machining process and increase your profits with ESPRIT 2016

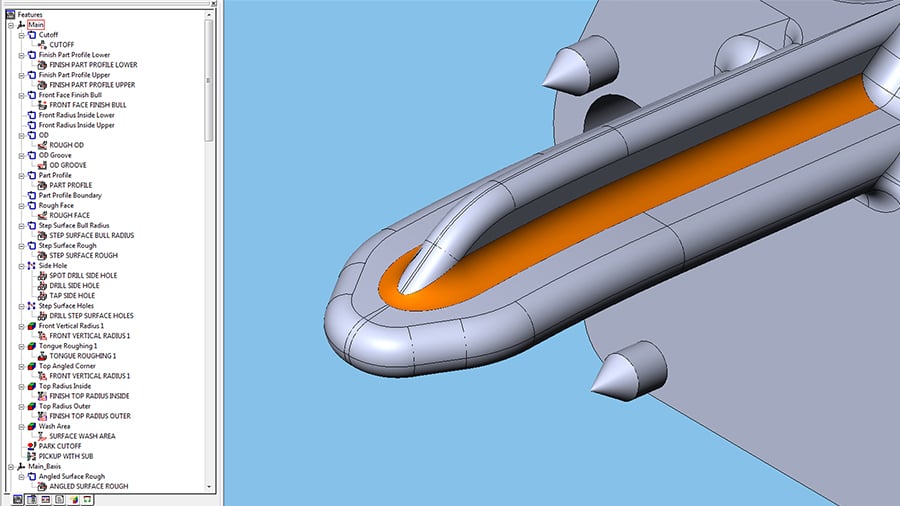

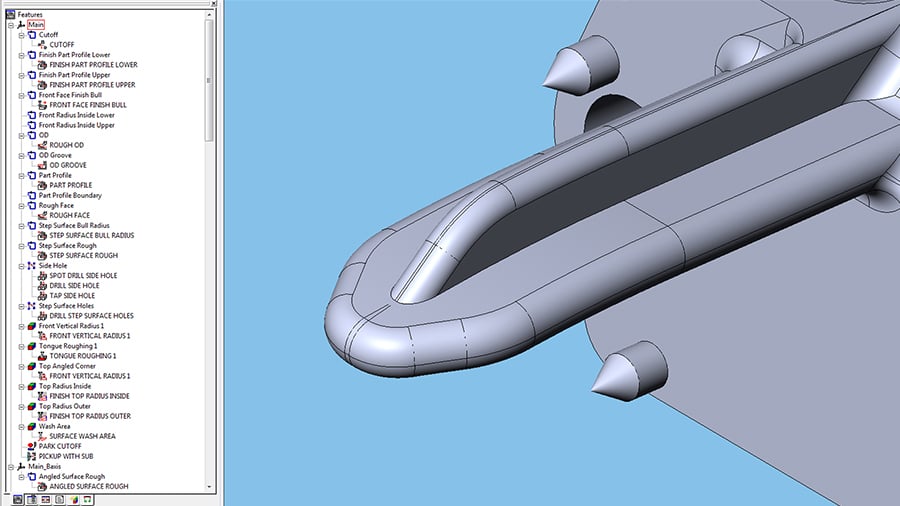

Camarillo, Calif. –- CAM industry innovator DP Technology Corp. has announced a new version of its pioneering flagship product ESPRIT®2016.ESPRIT 2016 features a new innovative high speed lathe roughing strategy, called ProfitTurning™ that implements ESPRIT’s new Physics-Based Cutting Engine. While traditional cutting strategies only consider the geometry of the part, ProfitTurning™ creates the toolpath considering multiple cutting factors and machine characteristics that impact machining performance. “ESPRIT 2016’s ProfitTurning toolpath maintains consistent cutting forces and chip loads, allowing cutting speeds to be significantly increased. By employing trochoidal turning and controlled engagement techniques, the ProfitTurning toolpath also reduces vibration and residual stresses, which in turn makes it particularly well suited to thin walls or hard materials, especially superalloys. The net result is significantly reduced cycle times and maximized productivity.”, said Ivan Krstic, R&D Director of Product Engineering at DP Technology.

Simulation speed also plays a pivotal role in CAM software and ESPRIT continues to be at the forefront of accelerating simulation without compromising accuracy or stability. ESPRIT 2016 includes increased simulation speed and higher quality surface finishing saving the user valuable time.

Advanced Tool Settings in ESPRIT 2016 provide CAM programmers enhanced tool management solutions. Additional Barrel Tool Support has also been extended to cover more 5-axis and 3-axis cutting cycles. Furthermore, Cloud-Enabled ESPRIT supports the MachiningCloud APP, which enables users to retrieve ideal cutting tool solutions and import them directly into ESPRIT with ease.

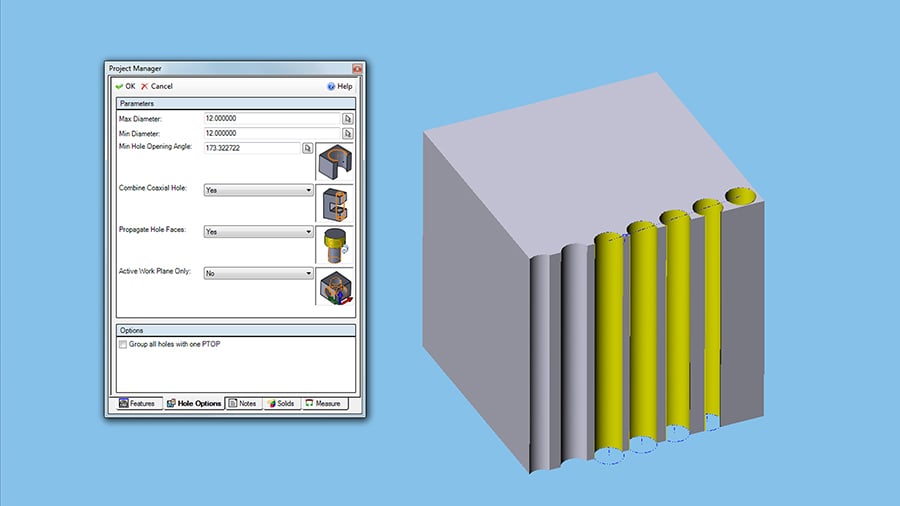

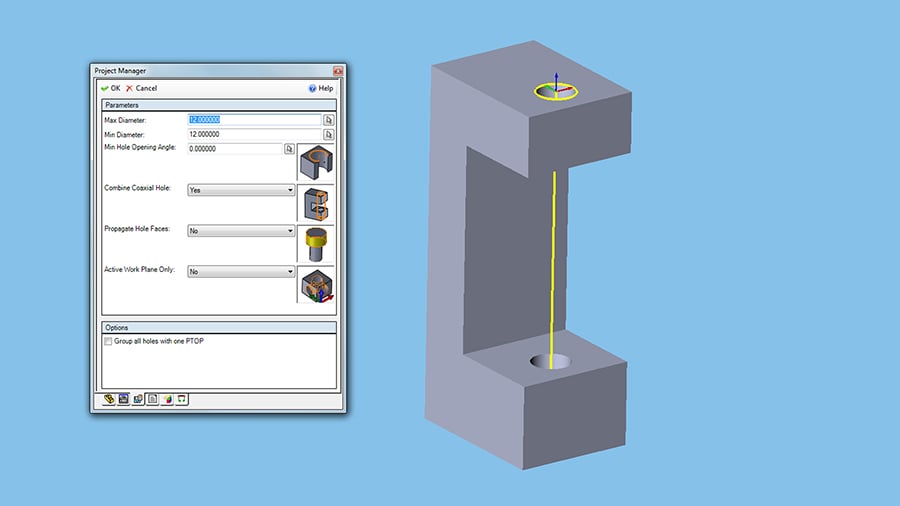

ESPRIT 2016 also features enhanced CAD recognition functions to correct and detect any acute unseen defects in imported CAD models. In addition, users can now edit or remove fillets or even extract a spine curve from fillets as a tool drive curve in machining operations. The new Hole Feature Recognition features in ESPRIT 2016 include automatically recognizing different types of complex holes and names them accordingly. ESPRIT also measures the curvature angle of open holes, making complex drilling operations more accurate and productive.

Wire EDM improvements in ESPRIT 2016 make rough cutting easier. The Optional Cut-Off Clearance in ESPRIT specifies additional clearance for cut-off moves to reduce the amount of grinding required. Another new Wire-EDM feature is the Optimize First Cut-Off, which protects the wire from rethreading where there is no pre-drilled thread hole.

Fluid 5-axis features in ESPRIT 2016 eliminates unwanted plunge-type moves in Swarf cycles, and smooths any concealed defects in Spiral Finishing part surfaces. The feed rate of Spiral Roughing can now also be increased for non-cutting moves to save cutting time. ESPRIT 2016 accelerates machining with increased simulation speed and innovative cutting strategies that save users programming time and optimize profits.

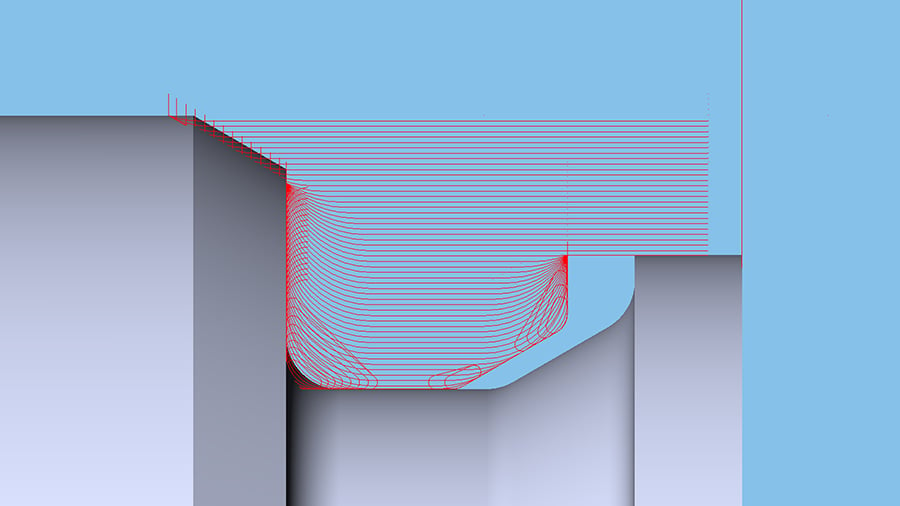

(a) Before removing fillet

(b) After removing fillet

Caption: Remove fillets from any CAD model to allow the tool radius to form the fillet during machining in EPSRIT 2016.

Caption: The New Hole Recognition feature in ESPRIT 2016 automatically recognizes different types of holes, including partial and coaxial holes and names them accordingly.

Caption: When holes share the same axis, they will be treated as a single operation with ESPRIT 2016’s New Hole Feature Recognition.

(a)

(b)

Caption: With the new Max Trochoidal Width parameter in ESPRIT 2016, users can now adjust the width of trochoidal movements from wide (a) to narrow passes (b) with ESPRIT’s ProfitMilling strategy in order to generate trochoidal movements for any size or shape pocket.