Eplan presents the new Smart Wiring Application Simplfying control cabinet wiring

Wiring a control cabinet requires a lot of time and expertise, however Eplan is making the process much easier: the Smart Wiring Application will be presented at the Hannover Messe. The software visualises the wiring and provides the necessary production data 100 per cent digitally. The ad-vantage: knowledge of the control technology is plugged into the system in the future. Users benefit from substantial timesavings for last-minute changes because the software also handles the often complex task of project comparison.

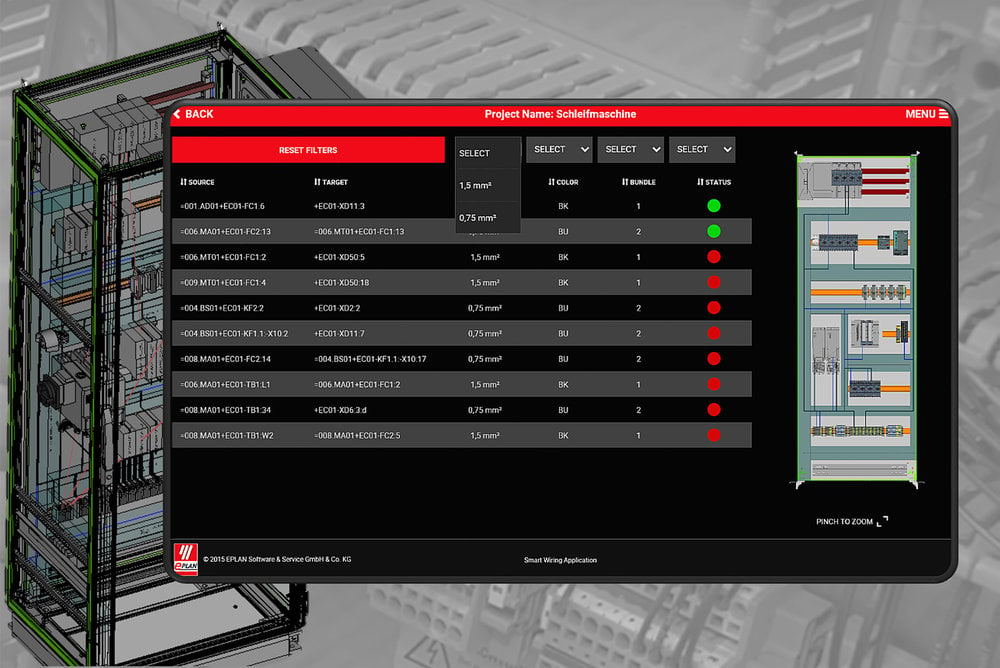

Smart Wiring Application: The Smart Wiring Application provides step-by-step instructions for the panel shop based on engineering data.

Monheim, Germany, 4 March 2016 – Smart Wiring Application: the name reveals what’s behind the new software – greatly simplifying the entire control cabinet wiring process. Eplan is presenting this new solution at the Hannover Messe. Whether it’s the source/target description, terminal point handling, cross sections, colour, wire length, end procedures or exact cable routing: the software provides a visualisation and the necessary wiring information and engineering data for mounting assembly within the control cabinet. The advantage: the schematic-based wiring – a time-consuming, error-prone process requiring a great deal of know-how – is no longer required. The Smart Wiring Application’s digital representation refers to the virtual model’s 3D-layout in Eplan Pro Panel. Yet the new application can be utilised to enhance productivity even without a 3D-layout. As an example, Excel lists with all the required connection information can be read into the program; the 3D visualisation of the routing pathways and assembly steps cannot be provided – however, the step-by-step execution as well as the comparison of various connection lists for last-minute changes remain available. Workers have clear information at all times about how far along the wiring process is as a whole, what still remains to be wired, which potentially necessary changes they must make and how to make them. The Smart Wiring Application will be available with the release of Eplan Platform 2.6 in September 2016.

System-guided application

A clearly designed menu describes every single connec-tion. This information is augmented with the equipment visualisation, including terminal points and the planned cable routing for the wires within the control cabinet. The software further provides information about the required wire diameter, the colour to be used and the defined terminal point handling – crimped or ultrasonic welding, for instance. Bundle affiliation is also exactly shown, which, taken together, means that every connection as well as every working step are clearly understandable and transparent. As soon as a connection is completely wired, it’s shown in traffic-light-principle green. This is tremendously helpful if several shifts are necessary to complete the work: colleagues can start wiring exactly where their predecessors left off.

Fast process for last-minute changes

The Smart Wiring Application really demonstrates its strength with last-minute changes to the project, which are simply registered in Eplan Pro Panel and then updated. Through the Smart Wiring Application, the two project statuses are compared to one another and the software documents all the differences, saving enormous amounts of time as compared to doing this manually. The software shows all the obsolete connections, those which have already been wired but must be removed, and which additional connections are required. This means that the times when wirers had to search and think about how the changes affect the entire wiring and manufactur-ing process have come to an end.

Background

Up to 43 per cent of the working time required to manufacture a control cabinet is consumed by the wiring (depending on its specific application). This process is extremely time-consuming and requires enormous specialist knowledge. What must be connected by wire, , and how can the required wires be optimally routed? These control-technology questions usually must be answered by using the schematics, which provide the basis for the cabinet’s wiring. As a result, highly qualified specialists pore over hundred of circuit diagrams and, page for page, work through the wiring for assembly and installation, the realisation of which may not always be unambiguous in every case. The Smart Wiring Applica-tion means that the time saved can be used more productively.

Advantages of the Smart Wiring Application

• Integrated workflow from customer requirements through engineering to manufacturing and testing

• 100% digital data

• Wiring without schematics

• Perfect visualisation

• Step-for-step directions for the worker

• Project comparison for last-minute changes

• Logging of wiring status

• Better scalability of workloads

Eplan at the Hannover Messe

Hall 6, Stand K16