Leveraging AI to take energy-use optimization to the next level

Alps Alpine has introduced Mitsubishi Electric’s EcoAdviser energy saving support software at its Taira Plant in Iwaki, Fukushima, Japan.

EcoAdviser drives initiatives toward sustainable goals at Alps Alpine’s Taira Plant.

Key Points

1. EcoAdviser boosts energy saving efforts, without having to replace the existing power management system.

2. Energy-saving ideas can be tested and verified on-site prior to their full implementation.

3. The Taira Plant is now exploring opportunities to leverage EcoAdviser’s built-in AI capabilities in the planning stage of the plan-do-check-act (PDCA) cycle for energy management.

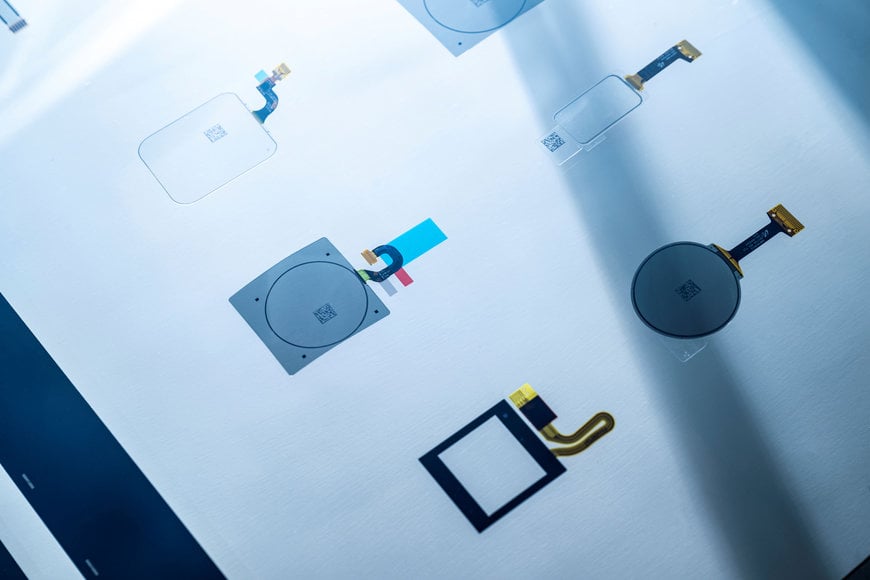

Alps Alpine’s Taira Plant manufactures touch panels for smartphones and car navigation systems.

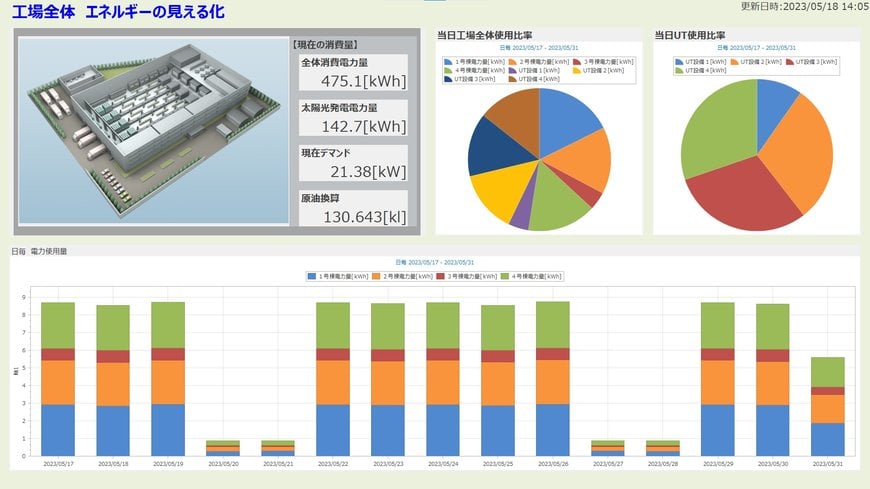

In line with the organization’s overarching efforts, the Taira Plant was already using Mitsubishi Electric’s EcoMonitorPro energy measuring unit alongside its SA1-III power management system from Mitsubishi Electric System & Service Co., Ltd. to visualize power consumption.

“Until now, our energy-saving efforts have been mainly focused on operational improvements, but we realized we would need a new approach to make RE100 happen,” says Kenichi Ōhira of Alps Alpine’s General Affairs Section, which is in charge of infrastructure management at the Taira Plant.

Kenichi Ōhira, Onahama General Affairs Section, Alps Alpine Co. Ltd.

Alps Alpine requested proposals from several vendors to help step up its energy-saving efforts at the Taira Plant, finally selecting an application that was based on Mitsubishi Electric’s energy saving support software EcoAdviser. “The deciding factor was that EcoAdviser could be integrated with our existing SA1-III energy management system. As well as being beneficial in terms of investment cost, this could help us streamline the project,” explains Ōhira.

EcoAdviser provides detailed visualizations of energy usage for the whole factory.

Ideally, when implementing a rapid cycle of hypothesis formulation and verification, on site workers should take the lead. This requires data and results to be presented in a format that can be interpreted instantly by staff, who may not necessarily have extensive expertise in energy management. The ability to provide a graphical display of relevant information meant that EcoAdviser was exactly what the Taira Plant needed. “Being able to visualize the effect of energy saving activities on operational expenses had a particularly big impact,” says Ōhira.

Dashboards that can be created in-house

Kohei Ogino, Onahama General Affairs Section, Alps Alpine Co. Ltd. explains, “Developing our dashboards in-house means we can add new screens as needed.”

When EcoAdviser was introduced at the Taira Plant, the team took on the task of creating new dashboards for data visualization. “Once you start using the software, you quickly realize that you are able to create custom screens to suit your specific processes, without having to outsource the task. This means you can optimize the system so that it can better help achieve your goals,” explains Ōhira. The team at Alps Alpine found that EcoAdviser could be used intuitively, enabling them to create in-house the screens they needed for effective monitoring. As a result, customized dashboards have been added to meet the requirements of the site as needed.

Kohei Ogino, Onahama General Affairs Section, Alps Alpine Co. Ltd. explains, “Developing our dashboards in-house means we can add new screens as needed.”

Reducing the training burden

Looking ahead, the EcoAdviser feature that Ōhira is particularly interested in leveraging is the AI diagnosis function. This feature will analyze energy information by cross-referencing production volume data, which they will link to in the future, to automatically identify energy losses.

“We’re not just looking to obtain energy data from our equipment, we also want to understand and leverage this to gain actionable insights. Before, we had to train specialist energy managers to do this, which takes time, but if that task can be performed by AI, it can help free up human resources to focus on other tasks. To put it in terms of the PDCA cycle, we are hoping that the ‘planning’ part can be done by AI,” says Ōhira. There are also plans to link the EcoAdviser software with production information to enable visualization on an energy per-unit basis, supporting the transition of our plant into a smart factory.”

“We would like to use the AI diagnosis function to help automate the ‘planning’ part of the PDCA cycle,” says Ōhira.

*1 RE100 stands for Renewable Energy 100%: a global initiative whereby companies commit to using 100% renewably-sourced electricity in their business operations.