www.industry-asia-pacific.com

17

'24

Written on Modified on

SEAH CHANGWON SPECIAL STEEL ORDERS SECOND ABB STIRRING TECHNOLOGY

ABB ArcSave will improve the productivity and resource efficiency of an existing electric arc furnace.

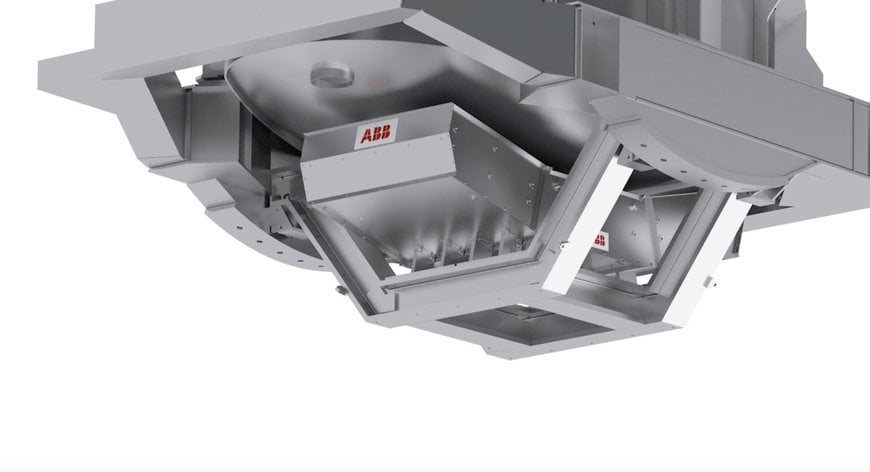

Unlike competing stirring technologies, ArcSave has no contact with the furnace melt, delivers a global stirring effect and is extremely low maintenance. Image ABB

SeAH Changwon Special Steel has placed an order with global technology company ABB for a second ABB ArcSave® electromagnetic stirrer for use on an electric arc furnace (EAF) at the SeAH Changwon Integrated Special Steel plant in South Korea.

The plant produces 1.2 million tons of steel and 1 million tons of steel products annually, putting SeAH in the global top ten of special steel manufacturers. Its stainless steel rods and wires made from high-quality special steel have end uses with customers in the automotive, energy and shipbuilding industries.

ABB ArcSave will be installed on an EAF that produces carbon and stainless steel and has a steelmaking capacity of 100 tons. The technology is expected to improve furnace efficiency, reduce energy consumption and overall operating costs on the continuously operated EAF at Changwon.

ABB's ArcSave will be used at the Changwon site in South Korea. Image SeAH CSS

The new order, which will be commissioned in late 2024, is the second from SeAH Steel and follows the installation of an ABB ArcSave electromagnetic stirrer on an EAF with a 70-ton production capacity in 2018. By introducing electromagnetic stirring and replacing an existing bottom gas stirring installation, SeAH was able to reduce bottom skull thickness from up to 1,000mm to less than 200mm. EAF productivity was improved by between five to seven percent, scrap handling costs were reduced by 70 to 80 percent, electrical energy savings were at between three and four percent and there were 40 percent savings on furnace refractory repairs. Other improvements included easier scrap bucket charging and better melt bath level control and tap weight hit ratio.

Requiring no physical contact with the bottom of the EAF, ABB ArcSave enhances metallurgical performance during the melting of large scrap items, reducing stratification via forced convection. This improves EAF operation by homogenizing temperature distribution and chemical composition, while speeding up scrap and ferroalloy melting compared with natural convection alone.

SeAH Changwon Special Steel has placed an order with global technology company ABB for a second ABB ArcSave® electromagnetic stirrer for use on an electric arc furnace (EAF) at the SeAH Changwon Integrated Special Steel plant in South Korea.

The plant produces 1.2 million tons of steel and 1 million tons of steel products annually, putting SeAH in the global top ten of special steel manufacturers. Its stainless steel rods and wires made from high-quality special steel have end uses with customers in the automotive, energy and shipbuilding industries.

ABB ArcSave will be installed on an EAF that produces carbon and stainless steel and has a steelmaking capacity of 100 tons. The technology is expected to improve furnace efficiency, reduce energy consumption and overall operating costs on the continuously operated EAF at Changwon.

ABB's ArcSave will be used at the Changwon site in South Korea. Image SeAH CSS

The new order, which will be commissioned in late 2024, is the second from SeAH Steel and follows the installation of an ABB ArcSave electromagnetic stirrer on an EAF with a 70-ton production capacity in 2018. By introducing electromagnetic stirring and replacing an existing bottom gas stirring installation, SeAH was able to reduce bottom skull thickness from up to 1,000mm to less than 200mm. EAF productivity was improved by between five to seven percent, scrap handling costs were reduced by 70 to 80 percent, electrical energy savings were at between three and four percent and there were 40 percent savings on furnace refractory repairs. Other improvements included easier scrap bucket charging and better melt bath level control and tap weight hit ratio.

Requiring no physical contact with the bottom of the EAF, ABB ArcSave enhances metallurgical performance during the melting of large scrap items, reducing stratification via forced convection. This improves EAF operation by homogenizing temperature distribution and chemical composition, while speeding up scrap and ferroalloy melting compared with natural convection alone.

www.abb.com