www.industry-asia-pacific.com

07

'23

Written on Modified on

Krones Detecting faults before they arise: Shopfloor Guidance optimizes line operation

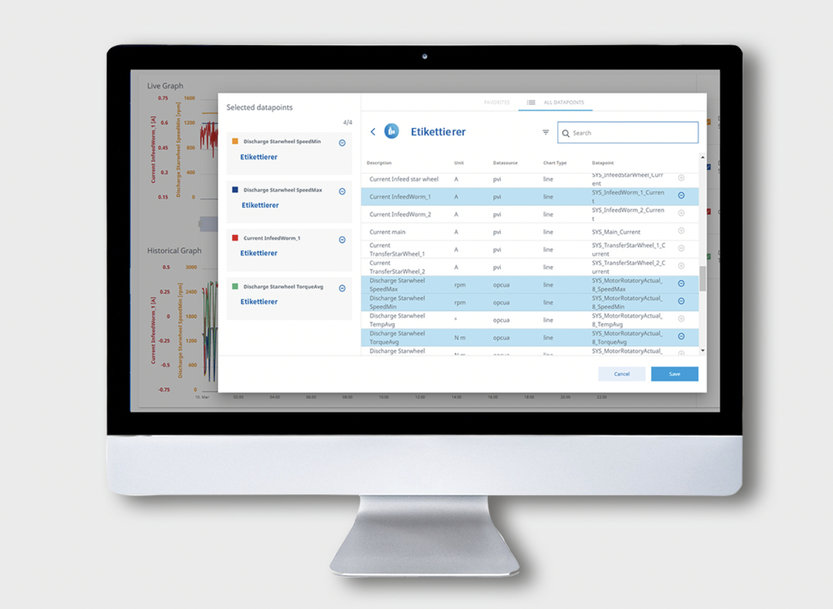

The new digital solution Shopfloor Guidance assists the operator team by monitoring factory processes.

It detects changes in the condition of machines at an early stage and initiates the measures needed to shorten downtimes and avoid resource bottlenecks. It automates the grouping and prioritisation of the requisite interventions and informs the relevant operators.

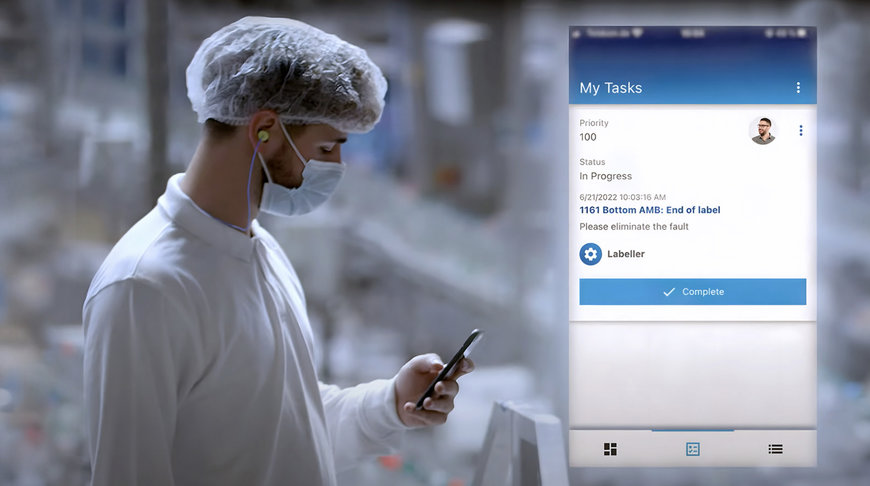

All machines are running at full capacity. The plant is filling a soft drink and the bottles are being passed through the filling and packaging line in quick succession. The production processes are supervised by the operator team and everything is going as planned. Suddenly one of the operators gets a message on her smartphone informing her that the labeller will shortly run out of labels. She goes to the machine at once and tops it up with labels, thus preventing a line stoppage.

That is made possible by Shopfloor Guidance, one of the many digital services developed by Krones for beverage producers. Shopfloor Guidance finds out where interventions are needed, notifies the relevant target group, supports them by issuing specific recommendations for action and in this way helps avoid machine stops, or at least substantially reduce machine downtimes. After all, stoppages can occur even in highly automated production environments – due to a lack of raw materials, for example. And planned downtimes may sometimes be longer than expected. In both cases, Shopfloor Guidance can provide assistance.

Promptly detected, problem avoided

That makes Shopfloor Guidance an important tool which supports line operators in meeting the daily challenge of staying on top of the various processes in their production line. Looking after several machines simultaneously also means they cannot always be in the right place at the right moment in order to respond promptly to any problems which arise. Shopfloor Guidance, on the other hand, detects problems at an early stage, immediately notifies the relevant operators by sending a message to their smartphone or smartwatch, and navigates them directly to the point where they are needed.

And that’s not all: The operating staff can contribute their own input to this solution. They can take photos and videos with their mobile devices and file them, thus compiling a customised knowledge database and turning Shopfloor Guidance into a solution tailored to the customer’s specific needs that gives clear recommendations for action. In a nutshell: Shopfloor Guidance makes sure all the requisite measures are efficiently grouped and prioritised in order to reduce the operating staff’s daily workload by providing properly targeted assistance.

Setting the pace for perfect production

The digital solution supports not only the operating staff but the shift managers as well. Thanks to round-the-clock condition monitoring, they are provided with easy-read production logs which record times, stoppages and faults in order to keep the shift managers up to date on their lines’ current status even during stressful periods. And the company, in turn, benefits from reduced maintenance outlay, higher capacity utilisation and increased profitability as a result. All of this combines to make Shopfloor Guidance an important communication tool which serves to improve plant efficiency and reduce downtimes – for operating staff, shift managers and the company.

www.krones.com