www.industry-asia-pacific.com

21

'15

Written on Modified on

Flexible Label Feeder for SMT lines brings affordable traceability to any business

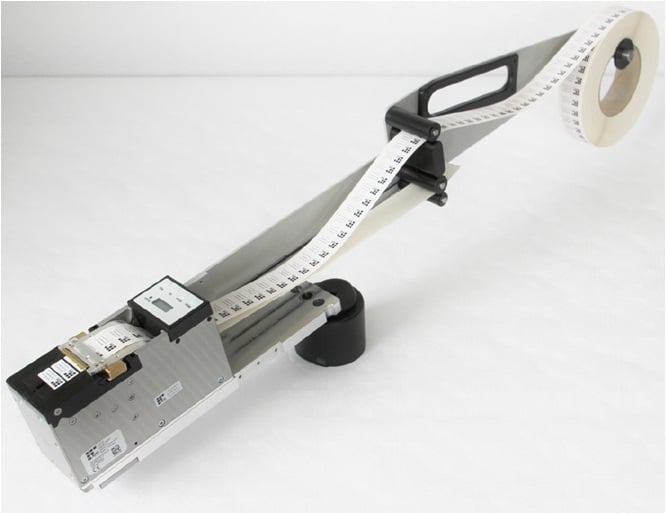

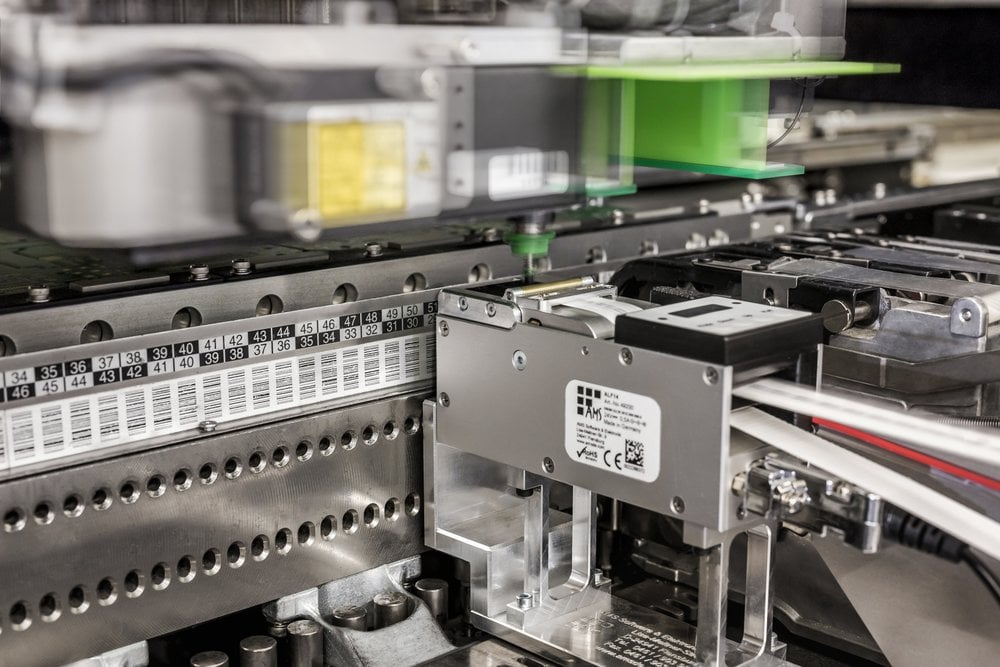

Worldwide identification specialist Brady, and Germany based AMS Software & Elektronik, have signed a partnership to offer high tech, automated and affordable traceability label feeders to electronic manufacturers throughout Europe, Middle East and Africa. “The combination of the flexible AMS ALF14 label feeder series with Brady’s advanced traceability labels offers users a highly efficient labelling automation solution for SMT lines in PCB manufacturing”, says David Walmsley, EMEA Business Development Manager at Brady.

“The need for traceability has never been higher”, Walmsley continues. “Gone are the days when it was driven and executed by the largest companies. These days, traceability demands are driven by industries and are driven down the supply chain, meaning relatively small companies are requested to comply. We believe that affordable, quality label feeders will form part of the solution that brings cost-effective traceability to the entire supply chain.”

Various sizes

The AMS ALF14 Label Feeder Series has a very competitive cost structure and a durable design that can easily be adjusted to common label sizes and tape widths ranging from 5*5 mm to 53*53 mm. “The ALF14-25, ALF14-40 and ALF14-55 drive down cost and increase quality because label liners do not need to be cut to size and because the feeders are not limited to one label size.” says Ivan Bajic, General Manager of AMS Software & Elektronik GmbH. “Supporting the needs of various industries, the ALF14 Label Feeder Series handle label material up to varying maximum label sizes and are the top choice for electronic manufacturing and special purpose machinery”. Moreover, all ALF14 models are modular label feeders which negates the need to replace the entire feeder if or when you replace your pick and place machines. Only the feeder machine adapter needs changing, at maximum 20% of the cost of a new feeder.

Easy to use

All three label feeders in the ALF14 Series are supplied with adapters for common SMT pick-and-place systems, making it an extremely flexible tool with a very short set-up time. To fit it to another machine, simply attach the corresponding adapter to the feeder and your traceability system is back up.

The label feeders’ fully automated label guidance system ensures reproducible label positioning for pick-and-place systems. Their simple and fast sensing and dispensing keeps up with the demands of modern pick equipment, while its compact design minimises occupied space in your feeder rack.

“The easy exchange of consumables, even with different label sizes, is a challenging industry request AMS focused on during product design. Every ALF14 Label Feeder can dispense a range of labels which enables fast and easy handling in daily operations”, says Mr. Bajic.

Specialised PCB Traceability Labels

Brady UltraTemp™ Label Series can all be supplied in either blank or pre-printed form to your specifications and ready for dispensing by the ALF14 Label Feeders. UltraTemp labels will stay intact and legible throughout the printed circuit board manufacturing process and can resist a range of chemicals, temperatures and high pressure while maintaining material and print integrity to enable complete traceability throughout the supply chain. Moreover, these labels are specifically designed to meet the needs of modern day automation. “Brady spent many years developing materials that are easy to dispense”, says David Walmsley. “Although only a label, if it doesn’t dispense properly, a production line stops and your traceability can be lost. Brady solved common problems when auto-applying labels and developed materials to overcome these issues.”

More flexibility

Brady UltraTemp Labels can even be printed on-site using a Brady printer coupled to the AMS ALF14 Label Feeders. If you need many different prints, adding a Brady label printer to your automated traceability solution enables you to print any barcode, QR-code or serial number in highly resistant ink on blank traceability labels for maximum flexibility that meets the demands of a modern day SMT line.

For more information, or for a free ALF14 demo, please email This email address is being protected from spambots. You need JavaScript enabled to view it..