www.industry-asia-pacific.com

31

'15

Written on Modified on

NSK bearings save €11,500 a year in MRO activities

The replacement of ball bearings is part of typical maintenance schedules when it comes to electric motors. However, when a German MRO (maintenance, repair and overhaul) provider was tasked recently with performing regular overhauls of electric drives for a prominent customer, a frequently recurring problem was noted: newly installed standard bearings would fail after three or four months.

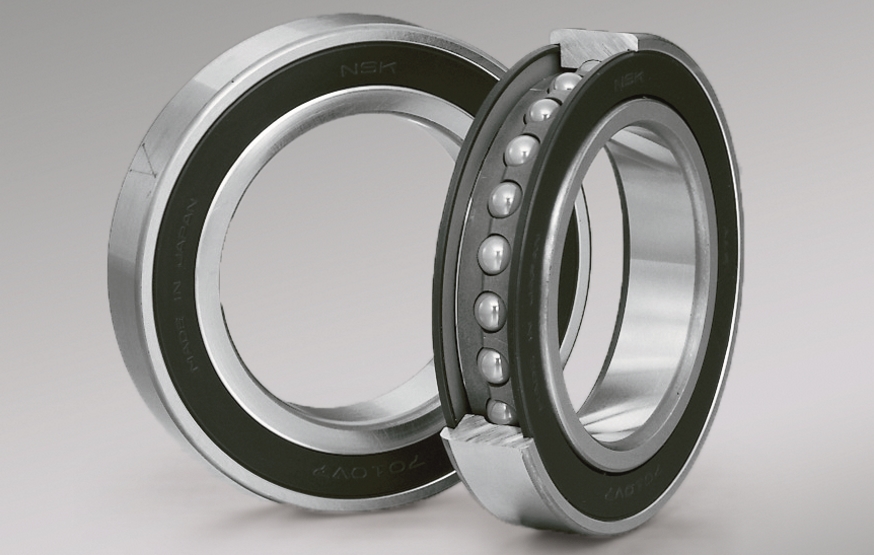

The AIP investigation revealed that premature failures were occurring due to the penetration of dirt, which in turn was contaminating the lubricant inside the standard ball bearings. As a result, NSK recommended switching to its sealed super precision ball bearings, a solution that proved so satisfactory that these bearings are now used for all electric drive overhauls.

NSK’s sealed super precision ball bearings excel in challenging environments thanks largely to non-contact seals that offer class-leading protection against contamination ingress, an effect that is achieved without any friction increase or motor speed reduction, and with no compromise to the specified energy efficiency of the drives.

For the customer of the MRO provider, the benefits have been extensive. In trials with 65 motors, the service life or maintenance interval of the electric drives climbed from four to more than 12 months, simply due to the change of bearing. As a consequence, the annual service cost within a one-year period has fallen to zero, compared with €11,500 spent in the 12 months prior to fitting NSK’s super precision sealed bearings.

As well as service life that has more than tripled, sealed super precision bearings are offering the end user several additional benefits. For instance, they have not only reduced noise and vibration throughout the drivetrain, but stopped grease leakage in vertical-type installations. They can also be fitted far quicker than standard unsealed bearings. For these reasons, NSK’s sealed super precision bearings are rapidly becoming the first choice in industry-wide electric motor applications – for both original parts and as replacement components fitted during routine maintenance regimes.