www.industry-asia-pacific.com

01

'23

Written on Modified on

BAUMÜLLER AND PARTNERS SHOW THE ENGINEERING OF THE FUTURE

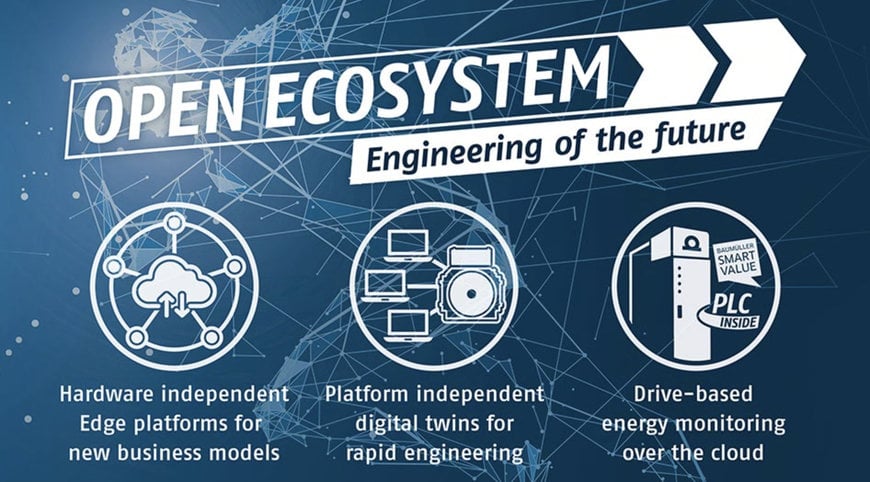

How flexible machine builders and users can work in future with PLC platforms, the digital twin and smart drive functions will be revealed to visitors to the Baumüller Group stand (Hall 7/A28) at the Hannover Messe, April 17-21.

“Industrial Transformation – Making the difference” – in line with the main theme of the Hannover Messe, Flecs Technologies, Schubert System Elektronik, MapleSoft, IniNet Solutions and Baumüller demonstrate how digital marketplaces can support machine building in future. Using the example of a 3-axis application, the partner companies show how associated simulation models and software solutions can be installed on all kinds of different platforms in record time.

Use case: Drive-based energy monitoring from the cloud

The first use case is about extending an existing application with further functions. If a user would like, for example, to use the “smart energy monitoring” function in their machine, they can acquire a license for it through Flecs Technologies’ web shop and use the Baumüller ProDrive parameterizing software to activate the license on the machine’s drives. Here, ProDrive serves as an interface between the online marketplace and the servo drive. The advantage: In this way, new functions can be added later.

With “smart energy monitoring”, the energy consumption of individual axes or the whole machine can be recorded and shown for the individual machine cycle. Users can thus, for example, determine and optimize the product carbon footprint (PCF) for their products.

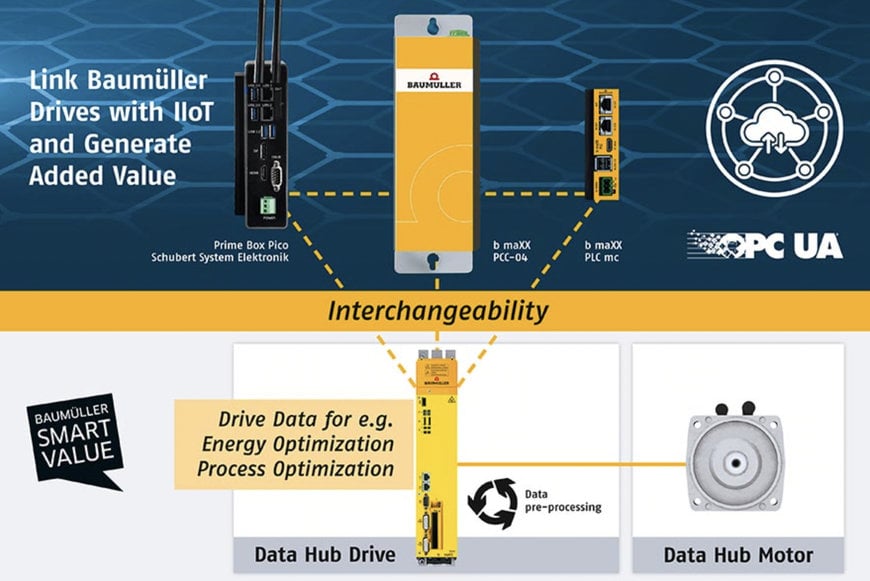

Use case: Hardware-independent Edge platforms for new business models

ProDataX from Baumüller enables data exchange via OPC UA between the drives in the machine and Edge PC or cloud. Regardless of the fieldbus used in the machine, existing available data from the drive such as power, current, torque, speed or position can be used, for example, to display these in a dashboard or to perform further analyses.

ProDataX is available to download from the marketplace. The advantage: ProDataX is compatible with all kinds of different control and IoT platforms, since Flecs enables interoperability with highly diverse apps. On the demonstrator, the IniNet app will be used to show data from the Baumüller drive in a dashboard. The connection between the automation level and the cloud infrastructure can be programmed graphically, directly in the browser.

Thanks to Flecs, the server, originally designed for Baumüller controls, can be run on the Prime Box Pico of Schubert System Elektronik. In this way, future automation software will be usable regardless of the hardware. A major plus for machine building. In future, the “best of breed approach” can be used to combine the optimal control/IPC hardware with the functions of different manufacturers to best meet the requirements of the respective application.

Use case: Digital twin independent of the engineering tool

With ProSimulation, Baumüller offers software for the simulation of electric drive systems. The package contains mechanics and controller models for virtual commissioning, which simulate, for example, the control behavior of the Baumüller drives realistically.

Through the Flecs marketplace, users can download controller models for drive simulation in the FMI standard (functional mock-up interface). These can be used with different simulation tools, for example, MapleSim. With the help of these models, it is possible to set up the digital twin of a machine drivetrain and commission it virtually. That saves time in the development process.

Conclusion

All use cases show how open systems increase flexibility for drives, controls and drive simulation. This enables machine manufacturers and users unimagined possibilities for combining automation components and software and opens up numerous new areas of use. When choosing the use cases, we focused on possible application with a functional licensing mechanism.

www.baumueller.com