www.industry-asia-pacific.com

28

'23

Written on Modified on

laser scanning without stitching

Aerotech will demonstrate high-dynamic, high-throughput galvo scanning with a gantry, IFOV and Automation1 controller at the Dublin National Manufacturing & Supply Chain Exhibition.

Around 140 exhibitors will come together at the Royal Dublin Society (RDS) Simmonscourt at the end of May to present their highlights from Industry 4.0, 3D printing, digital manufacturing, robotics and automation to sustainability, maintenance and asset management. In parallel, a specialist conference will cover red- hot topics around industrial manufacturing. Aerotech, known as a specialist for motion control and positioning systems, will demonstrate live to trade visitors how industrial high-performance scanning works today. The focus will be on the IFOV controller (Infinite Field of View). According to Aerotech, this is a unique and industry-leading solution for synchronising linear or rotating servo axes with laser scanners.

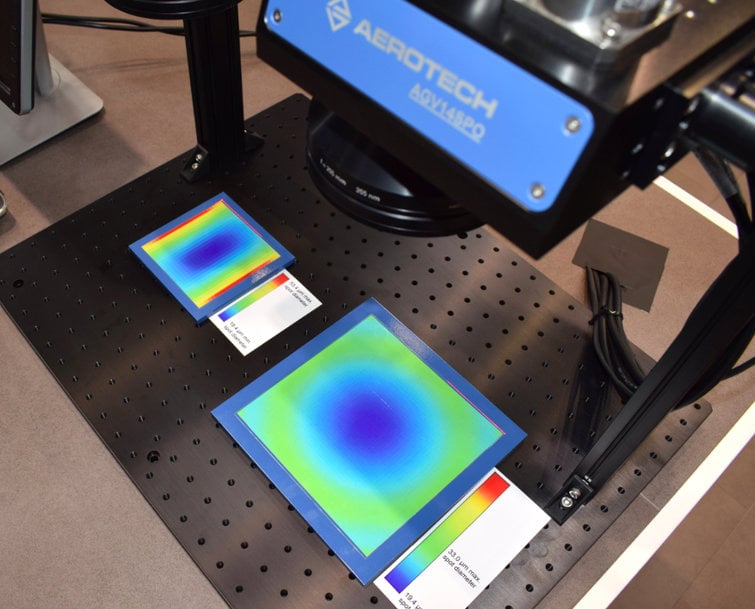

In order to increase the throughput and quality of laser scanning, multi-scanner systems with IFOV controllers from Aerotech are used. These enable complex, large- area and highly dynamic laser processing between several axes and an extension of the field of view without the familiar stitching. The field-proven Infinite Field of View (IFOV) function helps improve structural accuracies and general error prevention. By synchronising linear or rotary servo axes with laser scanners, IFOV improves throughput, eliminates stitching and part quality problems caused by overlapping and mismatched laser processing.

Multi-scanner systems with IFOV controller (Infinitive Field of View, i.e. opening angle) enable complex, large-area and highly dynamic laser processing between several axes.

One of the biggest challenges here is cutting out the individual displays from a much larger substrate. For this process step of micromachining, laser cutting has proven itself in practice. Since the laser spot size of galvanometer-based scanners is directly linked to the available working area, this poses a particular challenge: On the one hand, the speed of a galvo scanner is achieved, but on the other hand, the field of view is limited due to the laser spot size. "With our unique IFOV controller, we have solved this problem.

The resulting extension of the field of view and avoidance of stitching enables significantly higher scanning rates and thus an increase in productivity," Simon Smith knows from practical applications.

www.aerotech.com