www.industry-asia-pacific.com

07

'23

Written on Modified on

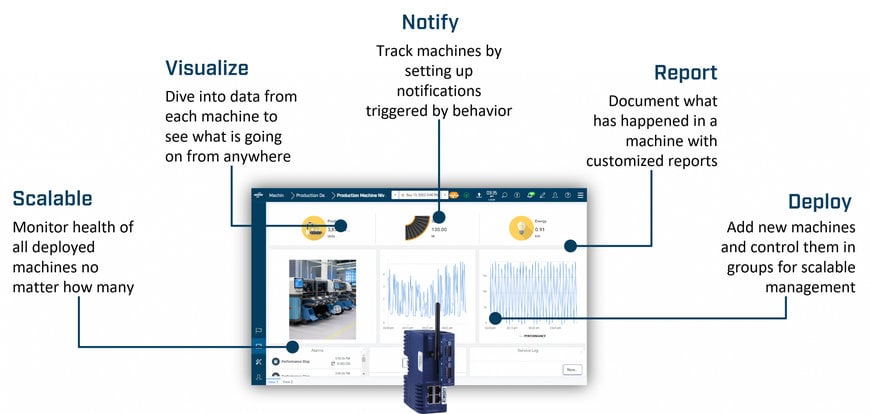

HMS Networks Launches Ewon Talk2M Visualization for Enhanced Machine Monitoring and Efficiency

Talk2M® Visualization Offers a Fast and Cost-Efficient Solution for Machine Builders to Visualize Data and Improve Decision-Making Processes.

Higher demands on machine builders

Industrial machines must be serviced and supported throughout their lifespan, but maintenance can become expensive as customers’ support expectations are increasing, and machine downtime becomes unacceptable among machine users. Furthermore, machine builders want their service technicians to manage a larger volume of machines. To stay competitive, they also need to enhance their machines with a state-of-the-art support infrastructure.

The key to leverage the profits of an increasing customer base – without increasing cost – is to be able to have full insight of machine performance and health. By visualizing the valuable data inside the machines, machine builders and their service technicians get the information and insights they need to improve support and make better decisions.

New visualization functionality in the Ewon® cloud

The new Talk2M Visualization functionality enables machine builders to easily visualize machine data to study trends, create dashboards, set up alarms and provide user-controlled access to any aspect of the customers’ machines. The machine data is collected by an Ewon Flexy gateway which in turn is connected to the proven and trusted industrial cloud solution Ewon Talk2M. As of today, more than 400,000 machines are already connected via Talk2M.

“With this new visualization functionality, machine builders are able to have a sophisticated, safe and complete support solution at even if their business is small”, says Sébastien Thinnes, Product & Marketing Director at HMS Networks Business Unit Ewon.

The new visualization functionality is available at no additional costs, for all users of Talk2M Pro.