www.industry-asia-pacific.com

15

'22

Written on Modified on

Inmoco: Advancing Sustainable Motion System Development

Meeting Market Demand for Environmentally-Friendly Solutions and Prioritizing Ethical Standards for Customers, Employees, and Suppliers.

When an OEM selects an automation partner, it’s increasingly important that they ensure the organisation can demonstrate the right credentials across the sustainability spectrum.

Sustainable industrial development heavily focuses on environmental factors, from CO2 footprint to the raw materials used in production. Of course, this is crucial to ensure stability for the global population of the future. It’s also a growing requirement from consumers. In turn, this means that it’s vital that technology end-users with brands to protect can demonstrate their sustainability credentials. For this reason, demand for sustainability is increasingly requested by OEMs to their partners through the supply chain. Investing in partnerships with sustainable technology providers means greater stability and reliability long-term.

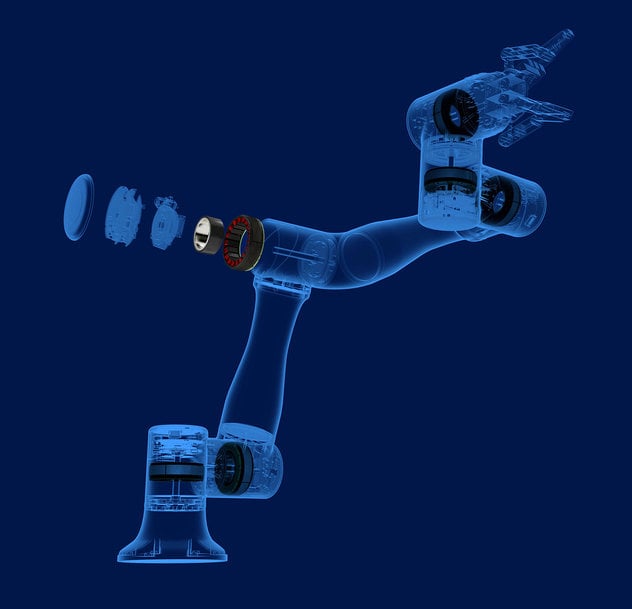

Innovators in industry investing in automation technologies have a lot to gain. Automated motion systems are intrinsically sustainable by virtue of their capacity to increase an end-user’s operational efficiency. Within the field of motion, the continued proliferation of robotics is not only increasing energy efficiency in production, but its uptake is also significantly minimising errors. Fewer errors mean less material waste, lower consumption, and more efficient manufacturing.

Removing barriers

The challenge is ensuring that the innovators – the market-leading OEMs of today and tomorrow – are able to access this technology and use it to best effect. A barrier to OEMs introducing robotics has been time of development, hence the focus of motion technology specialists like Kollmorgen in speeding up this process for broader robotics deployment. Artificial Intelligence (AI) and machine learning are developing the ability to drastically reduce the complexity of robot design and integration. Kollmorgen has over 50 years’ experience in motion, and its motors power thousands of robotics joints globally. With this data set, combined with extensive engineering insights, this is enabling Kollmorgen’s engineers to partner with OEMs and train their models for mass-scaling of robotics. This is bringing greater sustainability to industries all over the world.

Also important for sustainable development will be this approach of openness in development with OEMs and wider partners to create the opportunity for collaboration. Sustainable industries will increasingly mean deploying the most suitable robot technology for each application, and ensure that the technology operates seamlessly together in the same system. For Kollmorgen, a collaborative approach with OEMs is therefore key to success.

Sustainable processes

Technology development that enables innovators to create more sustainable solutions must also comprise materials from sustainable sources. For example, reputable technology vendors have provisions in place that prevent the use of conflict minerals [1]. These include raw materials such as tin and gold used within technology manufacture that come from global areas of conflict that surrounding mining and trading. This puts an automation vendor’s supply chain in focus, meaning that responsible OEMs will increasingly ask tech providers to demonstrate that their own supply chain is sustainable.

Moreover, sustainability is not just about the environmental outcome; at its core is people. This includes people involved in the supply chain around the world, so for example, it’s crucial for OEMs to ensure that their suppliers have processes that prevent child or forced labour, as well as ensuring fair treatment of the labour force. A sustainable supplier model also ensures equality and removes discrimination, and in its business dealings, it seeks to prevent all forms of corruption. A trusted technology vendor will be able to demonstrate these credentials through mechanisms such as a code of conduct for its own employees, as well as robust checks and procedures with its third-party suppliers.

Selecting a sustainable automation partner

When selecting a motion technology partner, their ability to develop solutions that optimise efficiency, from energy consumption through to material use, is of crucial importance. To make these gains achievable, the automation provider must also offer technologies that ensure fast development. Underpinning this development, it’s crucial that the automation vendor can show that its own processes, including material sourcing and the welfare of people involved throughout the value chain, are based on a sustainable model.

INMOCO is the UK distributor for Kollmorgen, and as a result, faces its own robust audit of sustainability. INMOCO’s engineering team regularly works with UK-based OEMs to develop sustainable motion and robotic solutions, interfacing with Kollmorgen’s global development capabilities.

The market is demanding a sustainable future. For OEMs to deliver this, ensuring sustainable partnerships isn’t just the right thing to do, but will ensure long-term commercial stability.

www.inmoco.com