www.industry-asia-pacific.com

18

'22

Written on Modified on

WITH THE ALREADY PROGRAMMED MACHINE TEMPLATES, BAUMÜLLER SECURES TIME AND COST ADVANTAGES FOR ITS CUSTOMERS

Industrial shredders crush materials made of plastic, wood, metal, and waste to a required size.

Depending on the requirements, each shredder is made up of different components, which are to be operated efficiently without damaging the machine. In addition to robust hardware, an extensive software package is needed to control the shredder. With the Motion-Axis Shredder software template, the automation specialist Baumüller in Nuremberg is introducing a template for the recycling branch to the market. It saves developers lots of time, particularly during a project’s start phase, and they can fully concentrate on the process programming. The template contains a large number of the required machine functions as well as motion modules for actuating the servo motors, templates for the machine visualization, and functions such as EtherCAT diagnosis, commissioning mode, load balancing, and water cooling control.

The already programmed subsystem contains frequently needed machine functions for crushing and can be easily loaded into the shredder control system. The movements then merely have to be parameterized. The machine programmer no longer has to worry about the basics during development. For the machine builder, this means a faster time to market, and significantly reduced development expenditure.

The software package is suitable for single and twin-shaft crushers, with and without feeder, and can be integrated into different hardware concepts.

Template with all basic movement control functions

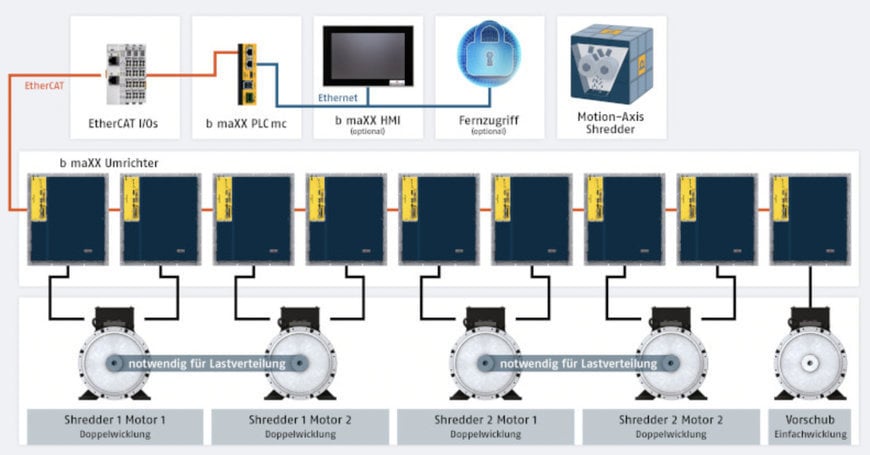

In addition to the shortened development time, with the Motion-Axis Shredder software template, machine manufacturers also benefit from the recycling industry technology experience. For example, the operation of two motors with load balancing in one shaft is already preprogrammed. The customer only has to integrate the existing communication interface, and can then, among other things, control the shredder shafts directly via a speed setpoint. The machine template can be used to control a maximum of two crusher units, each with two dual-winding motors as well as a motor for the feed.

An EtherCAT gateway (e.g. ethernet IP/EtherCAT slave) as well as an OPC UA server are available as the interface for the transfer of data to a higher-level control between different devices, for example, visualization or Edge controllers. Other interfaces can be added on request.

TTemplate for machine visualization and improved diagnostic options

In addition to the necessary motion libraries, among other things, the Motion-Axis Shredder template also contains general templates for implementation of the visualization. Thus, for example, the user interface can be used to diagnose the current template status or to check the interface values. It can also be used to activate a manual mode for setting up the control or for testing the subsystem. The subsystem can therefore be operated as a stand-alone and without a connection to the higher-level control.

The template also contains a function for commissioning. For example, if two motors are coupled mechanically to a shredder shaft, both motors can be actuated separately and thus the shredder motor can also be operated with only one motor. The function is particularly helpful for test purposes.

By using appropriate remote maintenance solutions, it is also possible to set up a remote connection to the control system. Thus, when service is needed, the machine can be accessed from anywhere in the world, and in compliance with the highest security standards.

www.baumueller.com