www.industry-asia-pacific.com

22

'22

Written on Modified on

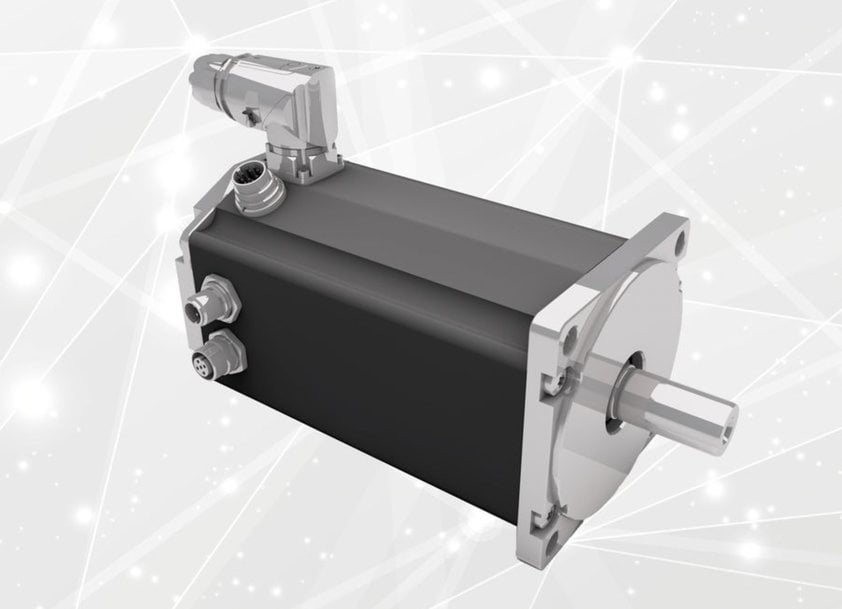

BG 75 JOINS THE DPRO FAMILY

Following the BG 66, BGE5510 and BG 95, the BG 75 is now also available as a dPro version. With a continuous output power of up to 590 W, peak power of up to 1700 W, and a peak torque of almost 5.8 Nm, the BG 75 dPro is more powerful than all other versions of the BG 75 series – with a supply voltage of just 24 or 48 VDC.

This means more power in the same space, allowing machines to be built even more compact in the future. These characteristics makes the BG 75 dPro the perfect partner in the application fields of logistics, robotics, as well as machine and plant engineering. It can, for example, be used equally in the food, semiconductor, and electronics industries, or can operate as a drive for AGVs (Automated Guided Vehicles). Connection and programming is as easy as for all motors of the dPro family and is done either via CANopen or one of the Industrial Ethernet interfaces PROFINET, EtherCAT or Ethernet/IP. The hybrid connector used for this reduces the cabling effort to a minimum.

The motor can then be programmed, controlled, and monitored via the "Drive Assistant 5" commissioning and configuration tool and/or MotionCode. To get the best out of your motor solution, our nexofox team will be happy to advise you - keyword condition monitoring or predictive maintenance. In addition, safety is a top priority at Dunkermotoren. That's why a certified STO function (Safe Torque Off) is possible for all BG 75 dPro versions, and even integrated as standard in the BG75 dPro with Industrial Ethernet. This allows the motor to be reliably switched off torque-free without interrupting the logic voltage, which eliminates the need for time-consuming referencing when restarting. With the new BG 75 dPro, there are no hurdles left on the path towards the realization of your smart factory.

www.dunkermotoren.com