www.industry-asia-pacific.com

20

'15

Written on Modified on

ARPRO® supports innovative light weight door panel

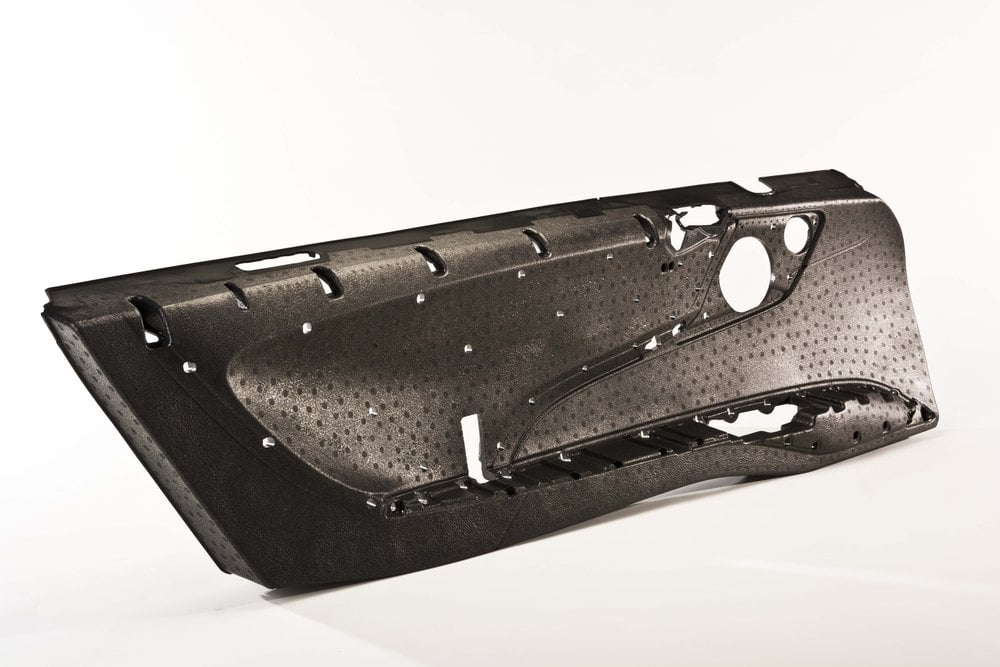

Driving sustainability, performance and weight reduction, JSP, the manufacturer of lightweight material ARPRO, has delivered a unique first in automotive interior design by enabling a new application for the door panels of the BMW i8.

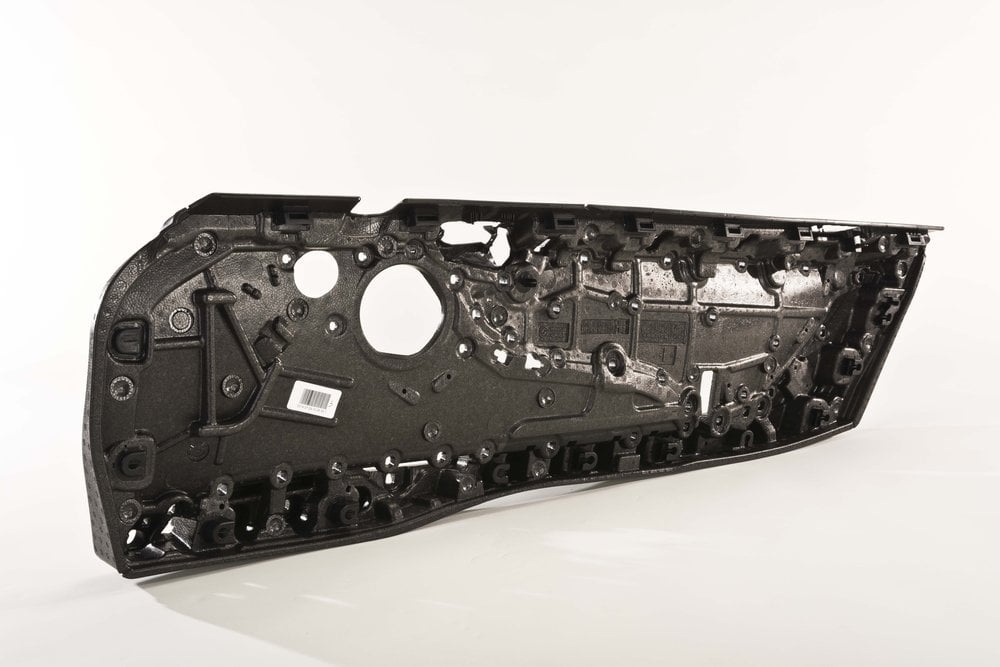

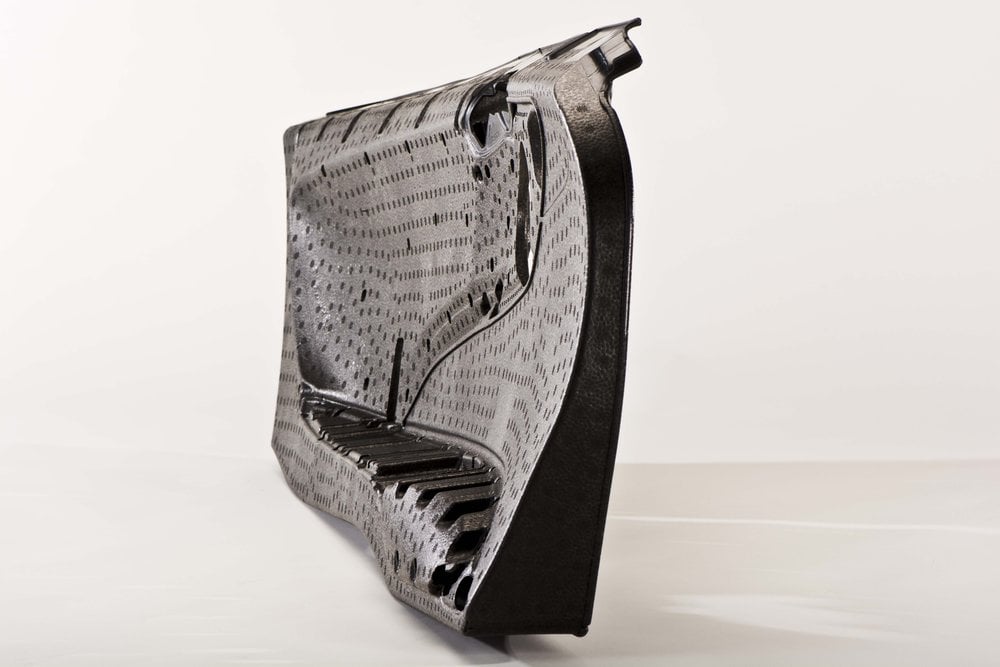

ARPRO’s ability to reduce weight, reduce tooling investment by 50 per cent and provide insulation of the door panel, along with integration of the cable channels and switches, has proven fundamental to the use of a scissor door design for the first time in a series-production vehicle.

ARPRO has already been widely used in BMW models including structural applications such as X5/X6 seat benches and the 5 Series seat back. Thanks to ARPRO’s flexibility and the ability to mould the material into customised shapes, Magna and JSP now also provide the BMW Group with an innovative lightweight-solution for the BMW i8.

JSP President and Chief Executive Officer for Europe Middle East and Africa, Paul Compton, explained: “Every gram saved by the ARPRO door panel means less environmental impact, while ARPRO’s energy absorbing capacity enabled crash pad functionality, despite small pack space and the constraint of a complex, aesthetic design”.

The development of the door panel was revolutionary, so testing at JSP’s eureka facility was rigorous, overcoming a number of challenges. The engineering process was particularly complex because of multi-functional requirements in one component. ARPRO needed to provide stability, structure and strength, as well as the integration of components: trims, loudspeakers and switches, and heat and sound insulation in a very thin wall. All this, with the overarching necessity for perfect tolerances appropriate to a premium car.

Equally challenging was the moulding tool. The radical design required multiple iterations to achieve perfection. The resultant part is smooth, sleek and contributes to the success of the interior design. The end result is technically accomplished, as well as beautiful.

Compton said: “Increasing automotive sustainability and producing a door that opens with ease and style is a great achievement, especially as the technology didn’t exist when we started this project. Our part in the BMW i8 project has been recognised and using ARPRO in the BMW i8 door panel has now led on to other exciting developments that will see car production take great strides forward in the near future.”

For further information about ARPRO® visit www.ARPRO.com