www.industry-asia-pacific.com

31

'22

Written on Modified on

Bearings for Steel Mill Roll Necks

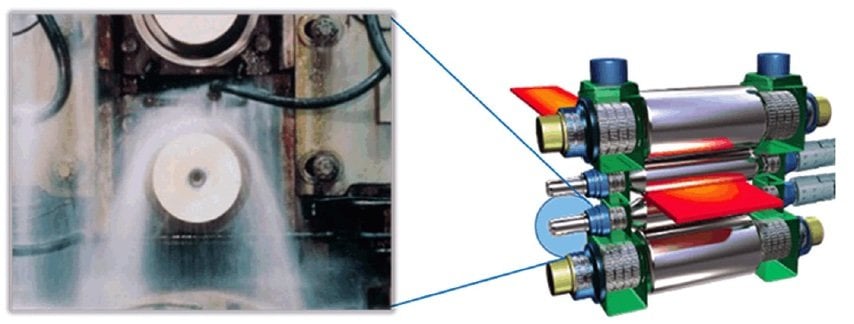

JTEKT Europe Bearings, the bearing division of JTEKT Corporation (formerly known as Koyo Bearings), specialized in the design and engineering of a wide range of rolling bearings for numerous applications, ranging from automotive and windmill applications to aerospace and tunnel drilling equipment, is now introducing the JHS® roll neck bearing series for use in Steel production equipment.

Background

Bearings used for steel mill roll necks must cope with heavy loads and high-speed rotation, under harsh conditions. In order to respond to these needs, JTEKT is permanently working to resolve related issues, such as developing better bearing materials and improving the bearing seal performance.

The challenge

Steel production equipment is operated in extremely harsh environments, where machinery is exposed to high temperatures, water and mill scale (a film of iron oxide that forms during the processing of hot iron). The bearings used in this equipment must continuously withstand heavy loads under high- speed rotation conditions. Also the oil seals needs enough sealing performance to withstand such harsh conditions. The newly developed product has been designed to improve the sealing performance and to significantly reduce the temperature increase and the amount of water intrusion, thereby contributing to a longer bearing service life and a reduction in maintenance costs for our customers.

The solution

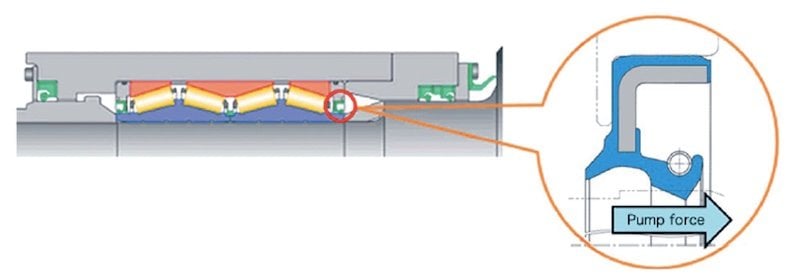

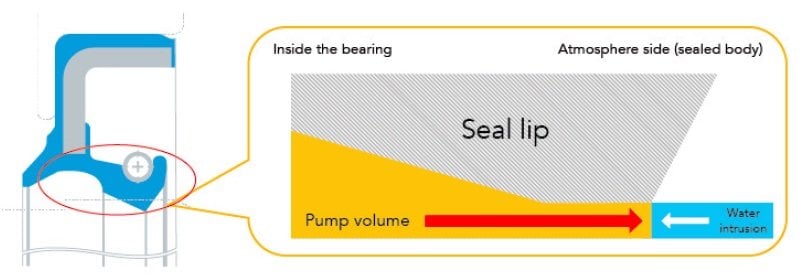

1. Change of the oil seal shape

By performing analysis on each design factor of the shape of the oil seal lip (the portion circled in red in the diagram to the right), we fundamentally reviewed the shape.

2. Leading to a longer service life

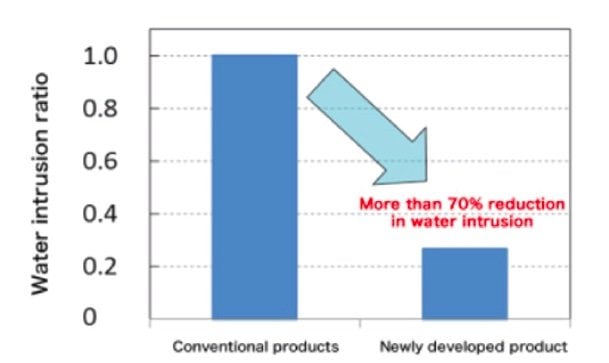

Thanks to this, we were able to succeed in maximizing the pump force (the force that prevents intrusion of water and foreign matter) and reducing the amount of water intrusion into a bearing by more than 70% compared to conventional products. In this way, we were able to reduce sudden bearing damage resulting from deterioration in lubrication, and achieve an oil seal with a longer service life than conventional products.

3. Reducing cost by application of nitrile rubber

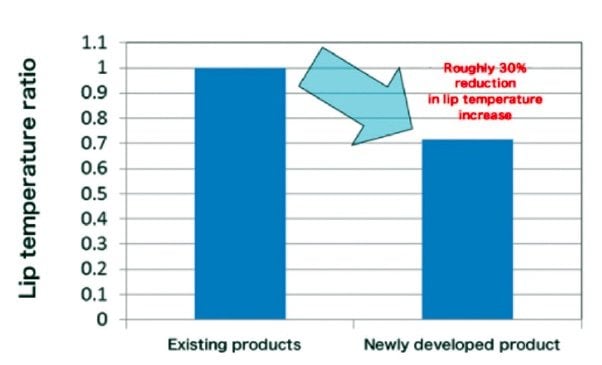

By changing the shape of the lip, the temperature increase of the oil seal was reduced by 30% compared to conventional products. This allows for the application of NBR (an inexpensive oil seal material widely used in bearings for steel production equipment) within the operating temperature range.

The results

JTEKT’s permanent challenge is to reduce customers’ maintenance costs.

With these improvements we realized both direct cost reductions (by applying NBR oil seal) and indirect cost reductions (by increasing service life).

www.koyo.com