www.industry-asia-pacific.com

26

'22

Written on Modified on

Lynx Software Technologies Partners with Google Cloud to Support Google Anthos Bare Metal and Google Visual Inspection AI Service

New video-based quality solution enables industrial and energy plant managers to securely deploy AI and other cloud-based workloads at the mission-critical edge to drive better business outcomes.

Lynx Software Technologies (Lynx), a leader in Mission Critical Edge, today announced that the LYNX MOSA.ic platform supports deployment of Google Anthos Bare Metal at the mission-critical edge. This enables delivery of containerized software services from the cloud such as Google Cloud Visual Inspection AI service, providing a validated solution for secure, video-based quality inspection in industrial and energy facilities.

Through this partnership, the new solution enables easy deployment of a) real-time image capturing on devices such as cameras on manufacturing plant floors and b) inference models built by Google Cloud Visual Inspection AI, that generate the insights and c) supervisory controller that connects to the Manufacturing Execution System (MES) and translates insights into action. Moreover, Lynx’s technology brings immutable isolation and non-bypassable security to give plant or facility managers confidence the solution meets the OT security requirements.

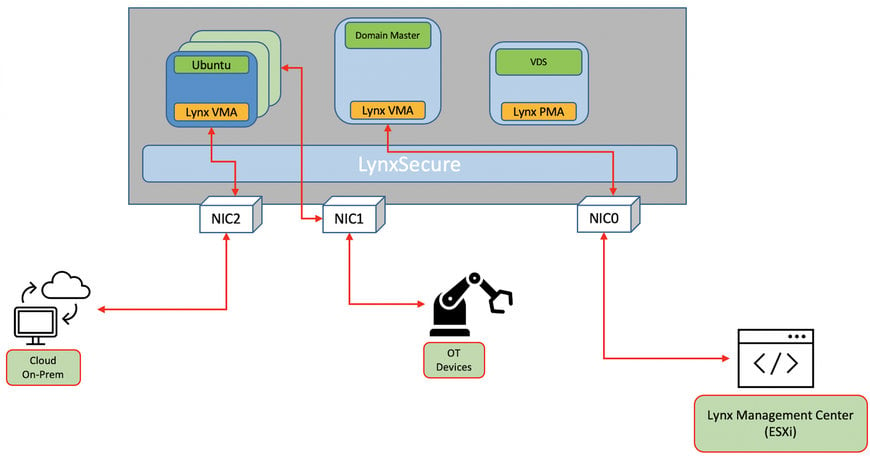

The solution’s use of Google Anthos bare metal support means that now an entire Kubernetes cluster can be run locally in as little as one hardware system at the edge, with Lynx enabled virtual air gapping providing isolation between the different parts of the system. Previously, the merging of operational technology (OT) and IT worlds - training AI and machine learning models in the cloud and deploying cloud-based workloads at the edge - posed security challenges in mission-critical industrial environments. Lynx ensures the three functions - image capture (camera), insight via inference engine (Google Anthos) and the action with a supervisory controller - are completely sandboxed with the option of secure one way (data diode) connections between them.

“As a provider of mission-critical edge, we’re thrilled to announce support for Google Anthos Bare Metal and Google Cloud Visual Inspection AI,” said Pavan Singh, Vice President of Product Management at Lynx. “With the new solution we’re jointly bringing to market, any containerized service can now be deployed to the mission critical edge without compromising security or performance. This partnership also marks an important step in our growing industrial ecosystem.”

For industrial and energy companies that are already feeling the strain of supply chain disruptions, labor shortages and more, this video-based quality system plays a significant role in enhancing performance and quality of output, while mitigating security risks. Through efficient visual inspection defects can be reduced by up to 10x, defective parts prevented from being shipped out, and insights can be gleaned into the cause of any defects to optimize processes

The solution is run on an Advantech MIC770, however, the LYNX MOSA.ic solution is able to run on various Intel and ARM processors. This flexibility means that various types of solution can have local/on-prem management while fully leveraging the benefits of cloud solutions.

This latest partnership builds upon Lynx’s growing technology partner ecosystem to accelerate the realization of mission critical edge within industrial settings. Other recent news includes partnerships with Bosch VHIT, Microsoft Azure and Eurotech.

www.lynx.com