www.industry-asia-pacific.com

11

'22

Written on Modified on

FANUC SHOWCASES A WIDE RANGE OF AUTOMATION SOLUTIONS AT ATX WEST

FANUC will demonstrate a wide range of automation solutions to help companies improve manufacturing efficiencies, reduce costs and stay competitive at ATX West. See us in Anaheim!

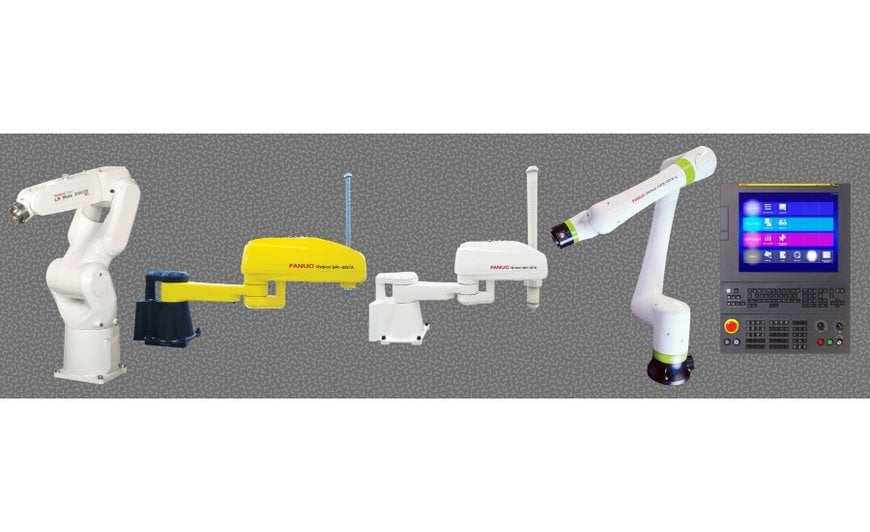

FANUC America, the leading supplier of CNCs, robotics, and ROBOMACHINEs will demonstrate a wide range of automation solutions to help companies improve manufacturing efficiencies, reduce costs and stay competitive at ATX West in Anaheim, CA in booth #4500.

FANUC CRX Cobots: Flexible and Easy to Use

At the show, a CRX-10iA will demonstrate packing health and beauty products. Visitors will have the opportunity to try the CRX’s intuitive hand guidance and easy-to-use tablet programming.

FANUC recently expanded its popular series of CRX collaborative robots with the new CRX-5iA, CRX-20iA/L and CRX-25iA. The new CRX cobots complement FANUC’s existing line of CR and CRX cobots that now total 11 model variations able to handle products from 4 to 35kg.

Designed for companies looking to increase their capabilities and overcome labor issues, FANUC’s CRX cobots are extremely robust and able to run for up to eight years without maintenance. In addition, interactive programming enables users to teach points using hand guidance or a tablet interface with drag and drop icons.

FANUC’s line of CRX cobots are very easy-to-use, reliable, and offer the flexibility to perform a variety of jobs including inspection, machine load/unload, packing, palletizing, sanding, welding, and many more. The CRX cobots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the CRX to work safely alongside people without the need for expensive guarding.

The CRX series supports several of FANUC’s advanced features including iRVision®, and is a perfect fit for any company looking to achieve higher efficiencies – even those that have yet to use their first robot.

Medical Device Assembly and 3DV Line Tracking Applications Feature the Popular FANUC LR Mate 200iD Robot

FANUC’s series of LR Mate 200iD tabletop industrial robots will be featured in two demonstrations at ATX West. The LR Mate 200iD robots offer a “best in class” work envelope for both upright and invert mount installations. Ten models include clean room and wash proof versions, each with various wrist speeds and reaches to accommodate even the most limited workspace. The LR Mate series was introduced 30 years ago, and since that time has become one of FANUC’s most popular robot models with over 70,000 units installed globally.

An LR Mate 200iD/7C robot, ideal for clean room and food environments will assemble small electronic medical devices (fingertip pulse oximeters). First, the robot uses iRVision® to pick plastic top covers and place them onto the bottom housing in the assembly fixture. A robot-mounted FANUC FS-15iA force sensor is used to push and pull the assembly as a quality check. Once the devices are assembled, the parts are disassembled and the process repeats.

Next, a FANUC LR Mate 200iD/7L uses an overhead mounted 3DV/400 Vision Sensor and iRPickTool line-tracking software to find and track plastic parts moving down a conveyor. The robot picks a part and places it into a bin. The system highlights the speed and accuracy of the 3DV/400 Vision Sensor and its ability to detect part depth and orientation.

FANUC 3DV Vision Sensor

FANUC’s suite of iRVision 3DV sensors are fully integrated and complete machine vision products for robot guidance and inspection. There are five 3DV sensors offering small to large fields of view from 50mm to 3M (3000mm) square. All of the sensors are lightweight and work as a fixed or robot-mounted 3D vision camera. The 3DV sensors are ideal for de-palletizing, kitting, bin/tote picking, presence/absence check, 3D visual line tracking and many more applications. The 3DV sensor is also a great option for 2D applications with low contrast or hard to find targets.

FANUC designs all of its vision hardware and software specifically for FANUC robots, providing customers with solutions that meet their production needs, and saves them the time and expense required by third-party vision suppliers.

FANUC’s Factory Automation Demonstration

Additive Manufacturing

The Factory Automation division will feature an additive manufacturing demo. Additive manufacturing, otherwise known as 3D printing, has been gaining popularity in industrial manufacturing to create prototypes, tooling and end-use production parts. Applications, including medical implants and aerospace parts, are growing as new hybrid machine tools combine additive manufacturing with CNC machining. The demo highlights FANUC’s capabilities in this growing market by incorporating a 3-axis machine equipped with a four-extruder head into a plastic 3D printer. FANUC 30i-B CNC equipped with the 21.5” Panel i H Pro will be featured on the machine to demonstrate its custom slicing and post-processing capabilities.

Power Motion i-MODEL A

FANUC’s Power Motion i is a perfect solution for a wide range of material handling motion control needs. The demonstration showcases PMi’s multi-path process capability to control multiple carriages via asynchronous G-Code programs. Offering powerful CNC and PLC technology together, PMi is more versatile than just a PLC, perfect for tasks involving multiple axes, paths, speeds and torque controls.

www.fanucamerica.com