www.industry-asia-pacific.com

30

'14

Written on Modified on

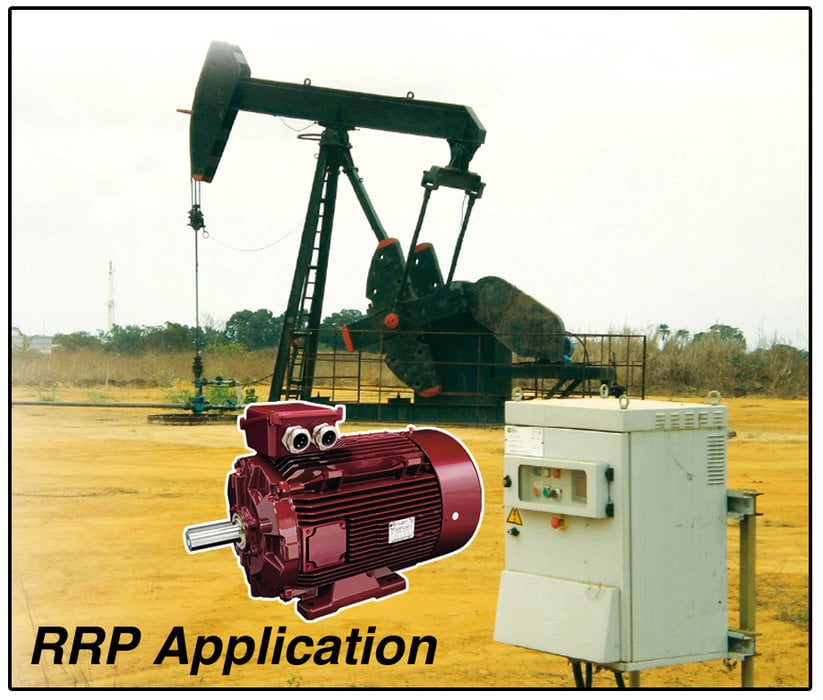

Emerson variable speed solutions enhance beam pumps in artificial lift process

Emerson Industrial Automation’s latest solutions, such as the Powerdrive FX four-quadrant drive in combination with an LSRPM synchronous magnet-type motor from the company’s Dyneo® range, are now delivering priceless advantages to increasing numbers of wells using beam pumps (RRP, reciprocating rod pumps).

Other concerns over fixed speed pumping include the limitation of monitoring possibilities and potential difficulties in detecting fluid pound. Furthermore, too many motors on the same electric network can cause a lagging power factor, driving the need for capacitor banks.

In contrast, variable speed technology allows pumping speed to be adjusted to field requirements, thus avoiding field work and the interruption of production. Further advantages include the ability to correct the oil field’s power factor without the need for capacitor banks, while VSD also provides soft starting, torque limitation and constant speed (reducing mechanical stress on the gearbox and rod).

In the past, because RRPs have a particular operating cycle whereby power is actually produced 15% of the time, this power had to be dissipated through bulky braking resistors. However, using the patented, compact, four-quadrant, C-Light Powerdrive FX, these issues are negated. For instance, there is no need for additional resistors – the power generated is fed back naturally to the power supply like with a line contactor in fixed speed. What’s more, harmonics are 25%, lower than a conventional six-pulse solution (independent of the load), while a better power factor means that Powerdrive FX also offers significantly lower line current.

Other advantages of Powerdrive FX include easy installation either outdoors or indoors, and a rugged design featuring tropicalised boards and a resin-treated line choke. In addition, Powerdrive FX eliminates the need for technicians to visit the site to retrieve well data, set speeds and reset any faults – all thanks to remote access capability.

Full production optimisation will rely upon pairing a Powerdrive FX with an LSRPM synchronous magnet-type motor from the Dyneo® range. Over a cycle, the torque profile of a RRP averages 50% of the nominal torque of the motor. In comparison with an induction motor, the higher efficiency of Emerson’s Dyneo® LSRPM over a wide speed and load range will lead to significantly reduced electricity consumption. Other benefits include its advanced design, which saves on maintenance through longer bearing life and reduced lubrication intervals. Furthermore, not only is the LSPRM motor smaller and lighter than a standard induction motor, it is also proven technology that does not require servicing any differently.

In conclusion, tests have proven that the combination of Powerdrive FX and LSRPM offers up to 20% in energy savings, reducing considerably the total cost of ownership compared with a traditional six-pulse drive and induction motor.