www.industry-asia-pacific.com

20

'21

Written on Modified on

Solving Copper Loss and Low Insulation Resistance in Subsea Production Systems

It is well known that the most common subsea electrical failure is as a result of water ingress into cables and connectors with degraded insulation. Failure of insulation resistance (IR) in a seawater environment can lead to serious, and potentially catastrophic, damage of the copper conductors of a cable unless the insulation failure is repaired.

With electro-hydraulic subsea production control systems, the delivery of electrical power from a topsides facility to the subsea equipment is generally considered a low-risk part of the system design. Of course, there is always some electrical analysis work to do up-front that considers the selection of dc or ac, single phase or three phase, voltage levels, umbilical electrical parameters such as conductor sizes. The analysis is driven by the field layout, offset distances, power demands and future field expansion requirements.

Since the electrical power system is critical for the operation of the subsea equipment, production availability will be directly impacted if the electrical system fails. Most subsea production systems utilise an Isolation Terra (IT) or ‘floating earth’ electrical supply system. The main advantage of the IT system and why it is used extensively in critical supply applications is that it guarantees continuity of supply in the presence of an insulation fault on one of the conductors. A truly fault-tolerant system – or is it?

As required by a number of International (IEC) and national standards, an insulation monitoring device (IMD) or Line Insulation Monitor (LIM) is mandatory in an IT system in order to identify a first fault, so that it can be repaired before a hazardous second fault occurs. The result of the IMD being connected is that the current flow being driven by the IMD results in copper ions moving into solution (sea water), thereby causing copper loss at the wetted surface of the copper conductor. It can therefore be concluded that the action of any IMD to monitor IR degradation in a cable which is submerged in seawater will cause damage to the copper conductors at the point where the conductor insulation is damaged.

Viper Innovations’ V-LIM product, however, has been designed specifically for subsea applications. One feature of the V-LIM is that it reduces the applied voltage and therefore leakage current in low IR conditions. This significantly reduces this copper loss effect when compared with competing IMDs on the market.

Solving Insulation Resistance (IR) Faults with Viper Innovations

There are two schools of thought as to how to deal with insulation resistance (IR) faults; monitor and leave until failure or replace equipment until the fault or faults are found. But what if there were a third option?

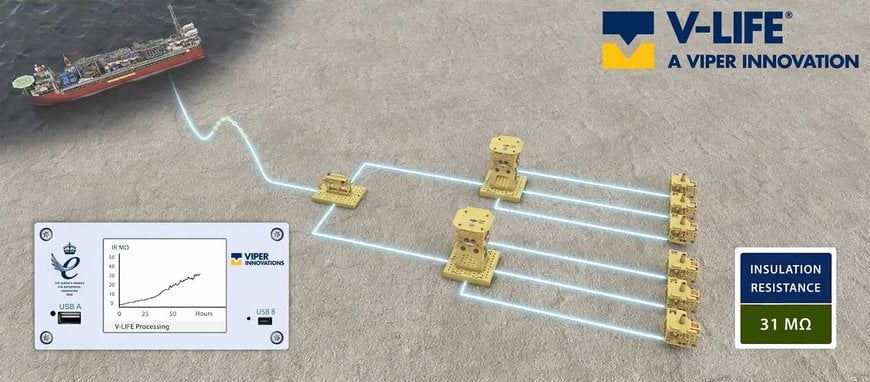

One way of reducing the impact of low IR is to deploy Viper Innovations’ V-LIFE technology. V-LIFE is an innovative software activated function of the topsides located V-LIM, that initiates an electrokinetic and electrochemical process within the damaged cable. The application of V-LIFE blocks any pores in the insulation with a precipitate, thereby removing the seawater electrolyte and increasing insulation resistance. As a result, the leakage current decreases and any copper loss is dramatically reduced.

In the scenario where there is a fault on both conductors, independent of any installed IMD, there will be a significant amount of copper loss from the umbilical or cable conductors. This copper loss or ‘copper corrosion’ results from the current leakage driven by the voltage applied to the umbilical for the surface to subsea power transfer. The copper corrosion resulting from this insulation failure could ultimately lead to complete failure of the electrical conductors.

The corrosion affects a wide area as a result of water penetration of the wire intersects. The copper corrosion has resulted in strands breaking.

V-LIFE will increase the IR on both thereby also reducing considerably this copper corrosion. If V-LIFE can be used to increase the IR to 3.5MΩ from an assumed starting point of 30kΩ, then the rate of copper loss will be reduced by a factor of more than four times over the rate of loss due to the standard third-party IMD. If the IR is increased to 30MΩ, then the factor increases to almost 15 times less copper loss.

Therefore, besides replacing failed cables and umbilicals, the only real solution to mitigate the copper corrosion is to activate V-LIFE on the Viper V-LIM. The V-LIFE process blocks any paths that the seawater will take to reach the copper and thereby reduce, by orders of magnitude, the corrosion of the copper and subsequently extend the life of the subsea electrical infrastructure.

www.viperinnovations.com