www.industry-asia-pacific.com

15

'14

Written on Modified on

RotoPaq Lite: value rotomolding temperature profiling solution from Datapaq

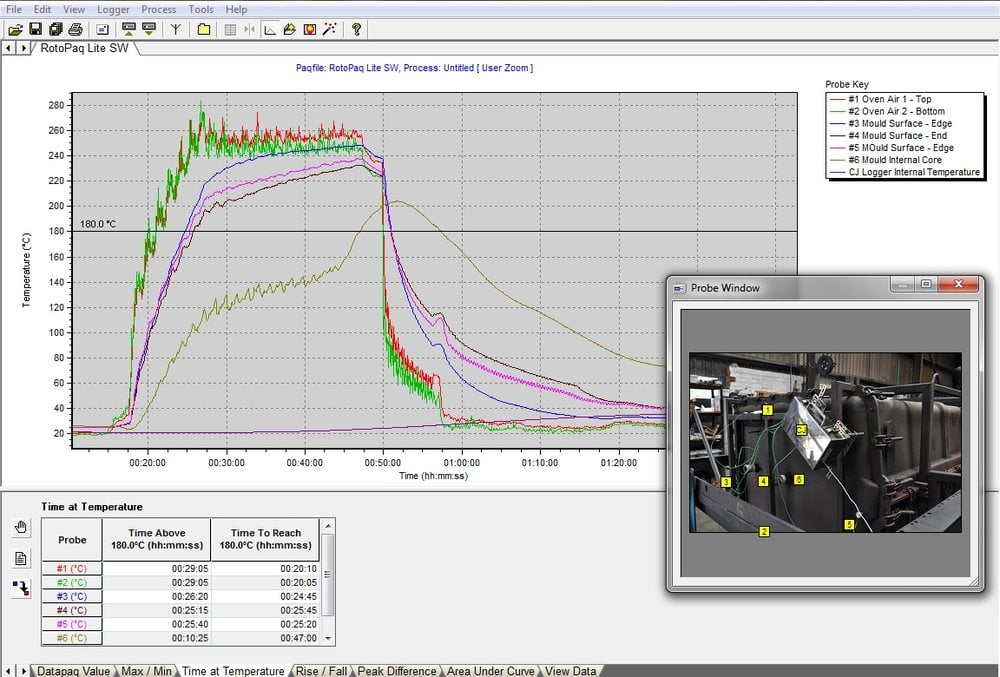

Cambridge, UK – Datapaq introduces RotoPaq Lite, an easy-to-use, compact temperature profiling and real-time monitoring system purpose-built for rotomolding applications. RotoPaq Lite helps users quickly set up and optimize this process used for the manufacture of hollow plastic products, thus improving product quality and process efficiency. It provides invaluable information on the phase transitions of the polymer while heating and cooling. The thermal barrier has been especially tailored to the logger type and the application. Dual phase thermal protection allows for continuous safe operation throughout the complete heating and cooling process and over multiple process cycles. The system withstands both air and water cooling.

The Q18 data logger compiles complete profiles from up to six thermocouples placed in the oven, on the mold surface, and inside the mold. Process as well as system data, such as internal temperature and battery life, are transmitted via radio to a connected workstation where they can be viewed in real time. All data can also be downloaded from the logger post-process. The Insight Basic software provides application-specific analysis and reporting functions for conclusive validation and documentation. Key functions include maximum temperature, time to reach & time above temperature, real time alerts and on-screen notifications, area under curve calculation (optionally above nominated threshold). The software can also be upgraded to Insight Professional to add Open Platform Communications (OPC) capability with the potential for live process feedback.

Figure 2: The software kit makes process monitoring as easy as never before