www.industry-asia-pacific.com

01

'14

Written on Modified on

OPC 120: Code Readers with an Innovative Polarization Filter that Reads Even on Reflective Surfaces

Vision Sensors today can be highly sophisticated systems, as illustrated by the new OPC 120 Series code reader for 1-D and 2-D codes. In addition to its functionality, compact design, and high speed, the special features of this device include a polarization filter for reading high-gloss materials and a PROFINET connection.

With the OPC120 Series code readers, Pepperl+Fuchs offers stationary readers for detecting and decoding 1-D and 2-D codes, such as barcodes and Data Matrix codes. The housing may be only 70 mm wide, 70 mm high, and 54 mm deep, but contains a CMOS imager, an LED flash, and a control interface. The code reader is capable of reading the majority of code symbologies that are currently in use and is available in two versions. The OPC120W design comes at an attractive price and can be used in many standard tasks that have normal reading speed requirements. By contrast, the OPC120P is the "high-end" design, reaching high reading speeds of 100 readings/s or tape speeds of up to 10 m/s.

Innovative Polarization Filter Technology Eliminates Reflections

A typical weakness of optical sensors is the fact that they are affected by unfavorable reflections that may be caused by external light or the camera's own light. Under normal circumstances, it is rarely possible to completely prevent reflections as they are dependent on multiple factors, including the reading angle of the code reader, the angle of the light source, and the orientation and structure of the surface on which the code to be detected is located. Codes on rounded, curved, or cylindrical objects made from reflective materials—such as ball bearings or metal tubing—are particularly difficult to assess, as various reading angles can occur during a single reading.

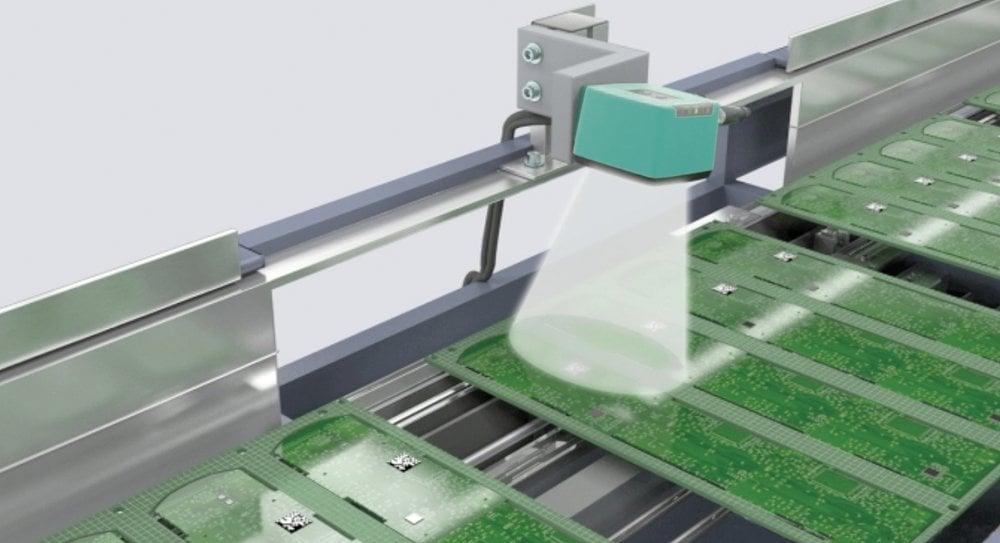

Developers at Pepperl+Fuchs have equipped the OPC120P with unique polarization filter technology that prevents faulty readings in these and similar scenarios. This technology eliminates harmful reflections and enables more reliable readings to be taken, even if codes are located on highly reflective surfaces such as metals, plastics, and printed circuit boards, or on film.

Image: Reliable reading on printed circuit boards

No More Refocusing or Parameter Changes Required

The exceptionally large reading distance range of 70 to 180 mm makes a significant contribution to the efficiency and flexibility of the Vision Sensor. The OPC120P is capable of reading codes on reflective surfaces and at different distances without mechanical refocusing or parameter changes being required. There is no need for auxiliary side lighting or adjustable lenses, as are commonly required when using other readers in challenging situations.

As well as detecting 1-D and 2-D codes, the code readers are able to check for the presence of variable textures and static graphics. The presence detection function ensures that variable structures—such as use-by dates and dates of manufacture—really are located at a pre-defined point, e.g. on food packaging. Logo detection allows non-variable features—such as company logos—to be detected and checked. The reader is able to read long codes by means of multiple image capture if it is confronted with codes that do not fit in one image. The device automatically combines up to six consecutive images so that it can easily decode extremely long codes or those on round objects.

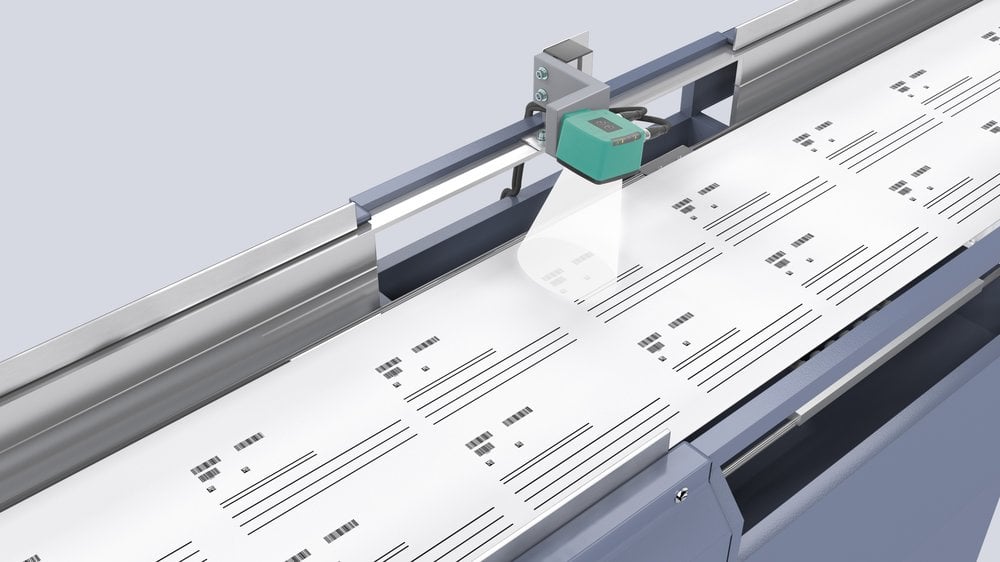

It is often the case that multiple codes need to be read in one application. The OPC120 allows up to four codes to be read in a single image capture. The device can not only read codes but also process up to four tasks, such as presence and logo detection, in a single image capture.

Image: Read up to four codes in a single image capture

PROFINET Connection with Integrated Switch

The OPC120 is available with all major interface variants, making it easy to integrate into systems and machinery. These interfaces include RS232, digital inputs/outputs, a connectivity option for a rotary encoder or trigger sensor, Ethernet TCP/IP, and the latest addition: "PROFINET." Industrial Ethernet supports a transfer rate of 100 Mbit/s and meets the real-time requirements of PROFINET IO Real-Time Conformance Class A. The developers have simultaneously integrated a two-port switch as an ideal solution enabling a direct connection to the next PROFINET device. This enables networks to be implemented in a linear topology without the need for additional coupling or switches. All configuration settings for the Vision Sensor can be accessed via PROFINET, while the Vision Configurator Windows software serves as a front end for parameterization purposes. Additional options offered by the code reader include access to the fault pattern memory, output of the code quality, and manipulation and formatting of the result strings.