www.industry-asia-pacific.com

08

'21

Written on Modified on

A Head Start Save Lives

Anyone suffering from symptoms such as a cough, fever or headaches and muscle pains wants to know whether it’s corona or simply a cold or the flu – especially during the winter season. And ideally as fast as possible. The necessary swab is performed quickly. For the subsequent analysis of the sample, it can either be sent to a large laboratory or a check can be performed for the patient on-site using a so-called point-of-care (PoC) system. In spite of the different areas of use, both have one thing in common: drives from FAULHABER guarantee reliable analyses.

Not only with corona tests is it often necessary to know the result as quickly as possible. Before starting treatment, certain lab values must often be on hand before the right measures can be taken in intensive care units, in outpatient departments or in doctors’ practices. Here, so-called point-of-care (PoC) analysis devices can make full use of their advantages: they are mobile and light, can be used flexibly and – above all – are fast. A result can be available in less than 15 minutes. The name reflects the most meaningful place of use of a PoC system: in the immediate vicinity of the patient and his or her treatment (point of care).

Prior to a surgical procedure or a drug therapy, a PoC analysis device is used to determine important parameters such as blood values, coagulation, blood gas values and electrolytes or check patients for infectious diseases such as influenza. Various technologies are used for the analyses, including fluorescence detection, polymerase chain reaction (PCR) and microfluidics. They play an important role in the fight against COVID-19 as well. The most reliable test for detecting a coronavirus infection is the PCR test.

Analysis devices for PoC use are nearly fully automated and, through the use of test strips or test kits, require only very few actions by the user. Depending on the function of the analysis process, miniature drive systems are used for the disposition of samples, for mixing with reagents, rotating, shaking or labelling of sample tubes. At the same time, the PoC systems must be compact and easy to transport and must occupy very little space on-site. In the case of battery-powered systems, a highly efficient drive solution is necessary for enabling a long operating time.

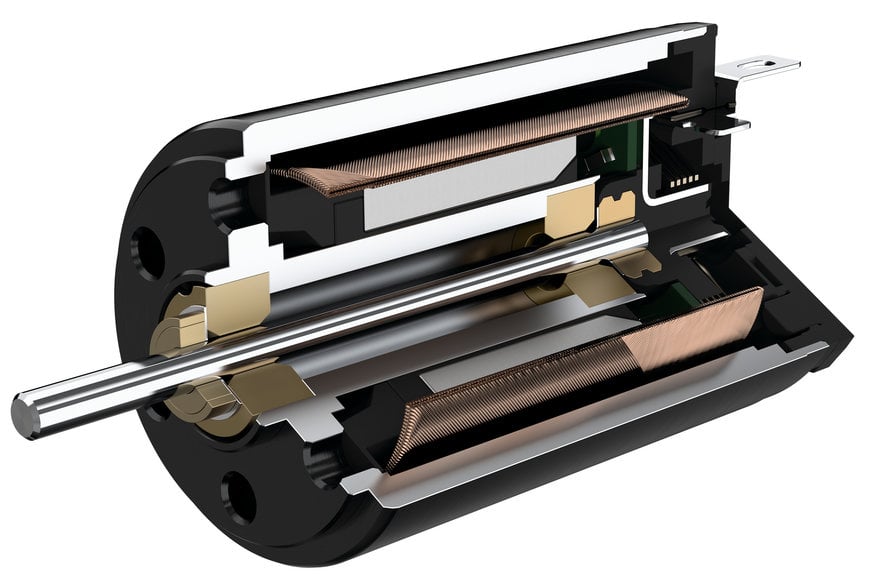

Drives for these applications must therefore be as compact and as fast as possible. FAULHABER DC-micromotors with graphite or precious-metal commutation or stepper motors are a good choice as they are compact in size, are highly efficient and offer a high power/weight ratio. In addition, they satisfy the requirements for high reliability, long service life, expanded product life cycle and low maintenance.

Fast diagnostics are decisive

A fast and highly specific diagnosis of infectious diseases such as COVID-19 or influenza through polymerase chain reaction (PCR) is the first choice for quickly determining what a patient is ill with on-site in a doctor’s practice or outpatient clinic. Patients thereby also have the certainty of knowing whether a runny nose is just the flu or if they have COVID-19. That is decisive, since with the latter contact persons must also be quarantined, and quick action can stop any further spreading. PCR is a commonly used method in molecular biology by means of which millions to billions of copies of a certain RNA/DNA sample can be produced through heat cycles in just a short amount of time.

Compared to a central laboratory automation solution with pre- and post-analysers, a PoC solution is more cost-effective, simpler, considerably faster and delivers relatively reliable results. There is also very little training required for personnel. Because just one sample can be analysed at a time with PoC, the overall throughput is limited and is considerably lower than what is possible in a large-scale laboratory. When it comes to performing a very large number of standardised tests, such as in the case of a mass test for COVID-19, there is no avoiding large-scale, automated laboratories.

The advantages of automation are obvious: it enables more reliable results with a much higher throughput than would be possible with PoC systems – and does so with low susceptibility to errors and minimal personnel costs. Automated solutions have therefore been indispensable for many years in so-called in-vitro diagnostics (IVD), i.e. the analysis of medical samples such as blood, urine and tissue. But automated processes in laboratories are also increasingly used in chemistry and in food technology. This can mean both performing individual processes in stand-alone devices but also in complex systems with a completely automated sample analysis.

Here, automation begins already when preparing the samples in colour-coded sample collection tubes. A scanner is used to detect which analyses are to be performed for the given sample. Depending on the requirement, the sample can also be separated into its constituent parts with a centrifuge. So-called sample taxis then transport samples on a conveyor belt or in small carts with wheel drive to the individual analysis stations. With these carts, which can only transport one sample at a time but also have several hundred other samples in the system, the appropriate analysis sequence can be performed fully automatically and yet be individually tailored to each sample.

Numerous drive tasks

The drives used in the lab must perform a number of different drive tasks. Smooth operation is only possible if the individual steps occur with high dynamics and precision. For example, each sample must first be clearly identified with a bar code, the stopper unscrewed and it must be ensured that only a part of the sample is used for the analysis. Especially for tests for COVID-19 or vaccine development, it is important that part of the sample be resealed and archived for any subsequent retesting and for archiving purposes. Needed during the preparation of the samples are, above all, small servo drives that, as part of a mobile component, perform changes in longitudinal or rotational position of the samples. Conveyor belts that transport samples in racks, on the other hand, require large, powerful drives.

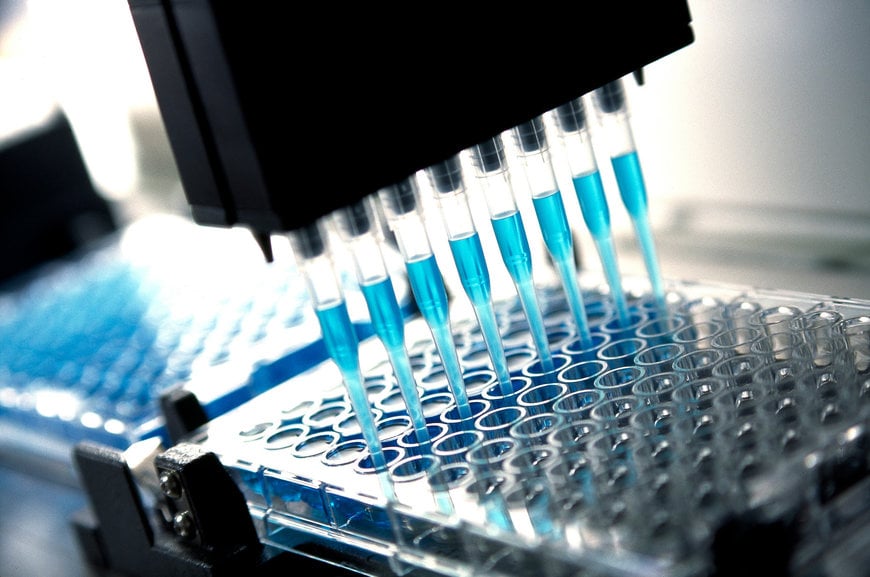

In the process sequence that follows – the transfer to a reaction vessel, such as a Petri dish or a test plate – the demands placed on the drive technology increase, as a range of different movements are required for pipetting, mixing, stirring and the handling of liquids. Repeated start-stop movements require a highly dynamic system in which extremely precise positioning is just as important as the speed of the pick-and-place or pipetting processes. Because the drive for the up and down movement of a gripper arm or pipetting head is usually located in the mobile component, this drive must additionally be especially light and compact.