www.industry-asia-pacific.com

11

'21

Written on Modified on

Operating floating photovoltaic systems economically and efficiently over long term

A prerequisite for the development and construction of today's photovoltaic plants is to operate them efficiently - economically and without downtime. Yet, as the number of utility scales plants increases the available space is decreasing. This means that new installation areas for solar systems need to be found. One possibility for this are floating solar systems. These new applications present a whole new set of challenges to operators and manufacturers, such as high humidity conditions, corrosive environments and direct irradiance.

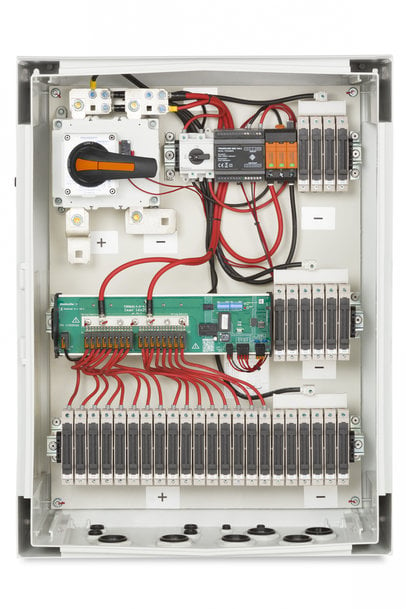

Floating PV systems are mainly used on freshwater lakes or ponds. This means that the systems could face more extreme conditions such as an ambient temperature of 50ºC while also having to bear humidity up to 100%. The Weidmüller PV Floating DC Combiner Box has been designed for an operating voltage of 1500 V DC which is the most used around the world nowadays. They are specially developed solutions for this use and are able to withstand high humidity conditions, corrosive environments and direct irradiance. In order to prevent corrosion-related component failure in floating applications, the PV Floating Box is specifically designed for ‘Severity B’ environments according to IEC-61439-2.

The development of a special PMMA sun cover to absorb income irradiance and heat, makes the module operational under direct irradiance. The cover is made of glazed polymer to increase reflection index and efficiently deflect incident radiation achieving lower temperature inside the combiner box. Fastening the PMMA sunshield cover to the enclosure door through stainless steel blind rivets ensures a permanent IP65 protection rating. Multivia cable glands are used to improve water sealing and provide a more robust design and lower the number of mechanized parts. A wide range of plug & play variants with 8 to 24 inputs is available for efficient use. The solution developed by Weidmüller was precisely tailored to these increased operating conditions and tested accordingly. All tests have been passed satisfactorly which has ensured the correct technical design of the floating combiner boxes solution.

String monitoring most important than ever

These complicated environmental conditions can affect all the components installed in the PV plant, thus can have a direct impact in the return of the investment (ROI). One of the key components are the solar panels. Every year the I-V curve of the strings is measured to ensure that the performance of the panels is according to their technical requirements. Nonetheless, it could happen that the I-V curve measured is not the expected one. This could be caused by different things but there are two which are the most important issues: The performance of the panels is reduced because dust or the PiD effect. Any of these two issues could be responsible for a direct reduction of the PV plant energy production.

Therefore, a string monitoring system will be helpful to detect any possible issues during electricity production. By monitoring the strings, it would be possible to detect not only any existing issues inside the combiner box, such as a blown fuse, but also that a string is not producing as much energy as the others. Through an early detection, the problem can easily be located in the PV installation and solved, avoiding any possible losses derived from it. The Weidmüller string monitoring system Transclinic 16i+ H has been shown as one of the most reliable and robust devices in the market and it can be also be used inside floating combiner boxes. This supports to get a bankability in the projects thanks to the high reliability and robustness of the product and the company Weidmüller.

Weidmuller’s footprint has overpassed the value of 18 GWp (more than 195.000 Combiner boxes delivered since 2007), which help us to provide to our customers a solid trakcrecord and reliability in our solutions.