www.industry-asia-pacific.com

08

'20

Written on Modified on

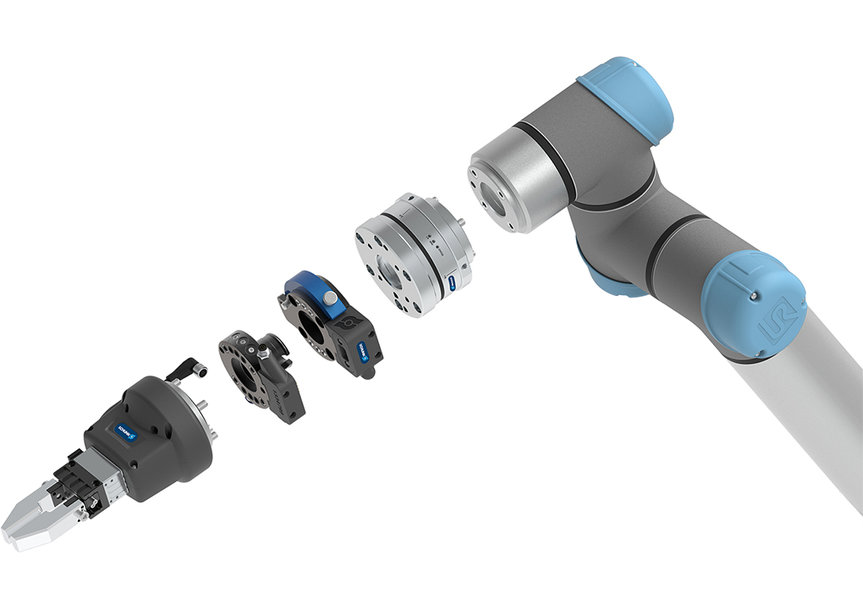

PLUG & WORK GRIPPER KIT FOR COBOTS FROM DOOSAN, TECHMAN AND UR

After having successfully launched the Plug & Work portfolio for Universal Robots, SCHUNK is further expanding the idea of simply equipping cobots onto the lightweight robots from Doosan Robotics and Techman Robot. The importance of both manufacturers has recently grown significantly and they are increasingly attracting the attention of users worldwide. With the Plug & Work portfolios, SCHUNK is reacting to this development and, among other things, adapting proven industrial components from its standard program to the various cobots.

The customized Plug & Work portfolios include pneumatic and electric grippers, co-act gripping modules for collaborative applications and quick-change systems. While the easy-to-operate, high-performance and cost-effective pneumatic grippers are predestined for conventional automation applications (where robustness is the primary requirement), the electric grippers, which are flexibly adjustable in terms of force and stroke, enable a wide range of applications with many variants. The grippers of the SCHUNK Co-act series are certified for direct collaborative use. All components are prepared for direct mechanical and electrical connection and can be installed and commissioned in just a few steps. Plug-ins simplify the programming, meaning that newcomers in particular will be able to benefit from fast and uncomplicated entry into process automation.

Wide range of components

In the segment of pneumatically controlled actuators, the modular systems contain the industrially proven, multi-tooth guided parallel grippers PGN-plus-P and centric grippers PZN-plus, the price-performance-optimized universal gripper JGP as well as the long-stroke grippers KGG and PSH. Micro valves for actuating the pneumatic modules are already integrated into the Plug & Work adapters. In addition, there is the electric small components gripper EGP, the electric gripper Co-act EGP-C, certified for collaborative applications, as well as the flexibly usable SCHUNK EGH with a freely programmable overall stroke of 80 mm, a virtually ideal entry level gripper for cobot-supported automation. The Plug & Work portfolios also include the SCHUNK SHS manual changing system, which has an integrated air feed-through, electrical feed-through and optional locking detection. As complicated set-up processes are not required, it facilitates the flexible use of cobots, and both SCHUNK grippers and other actuators can be changed in just a few short steps.

Versatile application possibilities

Since the components can be flexibly combined, and accessories and options are available from the SCHUNK catalog range, cobot applications can be adapted to different workpiece applications. With the SCHUNK online configurator based on eCATALOG solutions technology from CADENAS, solutions can be configured intuitively and downloaded in all standard CAD formats (either 2D or 3D) with just one click. A combinational logic here ensures that only technologically and mechanically possible configurations are implemented. The ready-to-connect Plug & Work portfolios cover a wide range of applications in both conventional automation and collaborative applications. They are equally suitable for newcomers to automation and professionals in the machining industry, the automotive and electronics industry, logistics and other sectors that want to tap into the potential of robot-based automation with the help of cobots.

www.schunk.com