www.industry-asia-pacific.com

07

'20

Written on Modified on

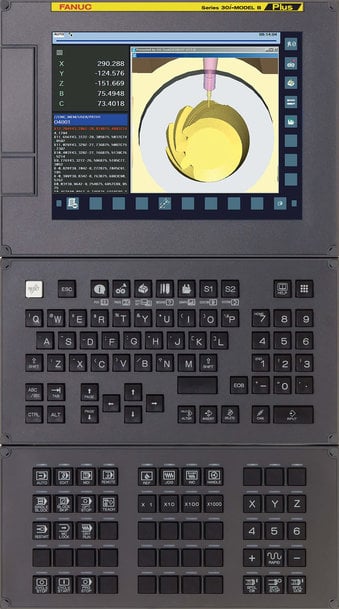

Optimized 5-axis Post Processor for FANUC CNCs

FANUC America has introduced a new post processor designed to optimize 5-axis capabilities in FANUC CNCs.

Mastercam’s new post processor unlocks faster and more accurate “art to part” FANUC CNC capabilities.

FANUC America, a leading factory automation solutions provider, and CNC Software, global leading CAM systems provider of Mastercam, introduce a new post processor designed to optimize 5-axis capabilities in FANUC CNCs. The new post processor allows advanced machine tool operators to reduce their cycle times while boosting part accuracy, particularly for CAD/CAM generated 5-axis simultaneous contouring part processes.

A growing number of manufacturing industries, such as aerospace, medical and mold & die job shops, are incorporating 5-axis simultaneous processing in their operations. By optimizing FANUC CNCs with this new Mastercam post processor, machine tools will be able to produce parts–modeled in the CAD system—more precisely.

“For 5-axis simultaneous contouring, a quality CAD/CAM system is critical,” says Rick Schultz, Aerospace Program Manager for FANUC America. “FANUC has worked closely with CNC Software to make it easy for programmers to create optimal tool paths using the advanced algorithms available in the 5-axis Milling Standard Package for FANUC’s 30i-B and 30i-B Plus Series controls.”

Key functions in the Milling Standard Package for FANUC controls include Tool Center Point (TCP), Workpiece Setting, Error Compensation (WSEC), Easy Setting Function to support multiple acceleration and process profiles, and advanced lookahead algorithms AICC II with Smooth Tolerance Control+. This package used with the latest FANUC-controlled machine tools and the new Mastercam post processor is designed to power the future of advanced 5-axis machining.

“This new Mastercam post processor unlocks the full potential of machine tools that come with the 5-axis Milling Standard Package,” explains Schultz. “Shorter cycle times with better path accuracy and mirror surface finishes will set a new standard for machining with Mastercam generated code.”

www.fanuc.com