www.industry-asia-pacific.com

28

'20

Written on Modified on

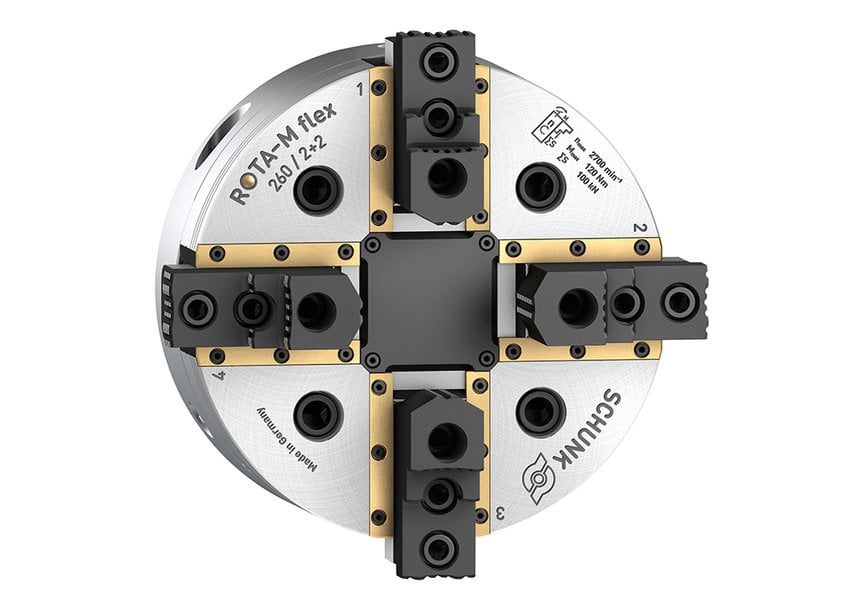

SEALED 2+2 JAW CHUCK WITH LARGE COMPENSATION STROKE ALLOWS MAXIMUM FLEXIBILITY ON MILL/TURN MACHINES

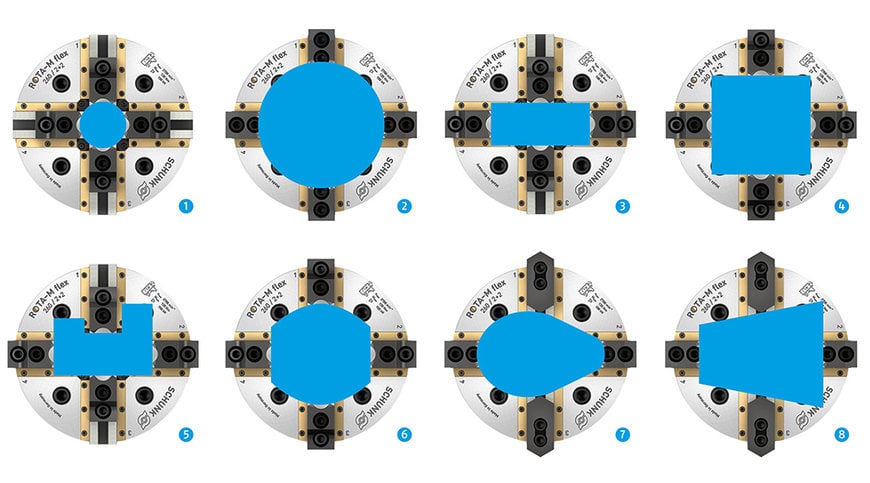

Centrically compensating 4-jaw chucks are used for clamping a wide range of workpiece geometries precisely and efficiently on mill/turn centers: round as well as square, rectangular or geometrically unshaped.

To meet the increasing demands of the market, SCHUNK has developed the low-maintenance 2+2 jaw chuck SCHUNK ROTA-M flex 2+2, which has a particularly large compensation stroke by virtue of a compensation mechanism (patent pending): Depending on the size, this is between 5.1 mm and 10 mm per jaw – more than with any other 4-jaw chuck on the market. This increases the flexibility for users with regard to the workpiece geometries that can be clamped and the variety of possible applications. In many cases, a single ROTA-M flex 2+2 will be sufficient in the future to flexibly cover a wide range of part geometries.

Sealed guideways

Special seals located on the guideway prevents grease from being rinsed out and the clamping force from being lost gradually. In this way, precise chuck function is ensured, even at low clamping forces. At the same time, the seals protect the chuck body from chips and dirt, thus increasing process reliability and extending maintenance intervals. To increase safety, the SCHUNK ROTA-M flex 2+2 is self-locking and the clamping status is indicated via safety indicator pins. In the standardized sizes 260 to 1,200, the chuck achieves high clamping forces of 100 kN to 180 kN with a jaw stroke of 9.5 mm to 17.8 mm.

One lathe chuck for everything: The compensation mechanism (patent pending) enables a significantly larger compensation stroke with the SCHUNK ROTA-M flex than with comparable lathe chucks. This increases the flexibility with regard to the clampable workpiece geometries.

Standard extras for the large sizes

From size 800 upwards, users also benefit from a weight-reduced design, the chuck face is equipped with grooves, and fixed workpiece stops enable additional use as a vise. Furthermore, the large sizes are also prepared for use on vertical lathes. To enable users to make the most of the diversity of the world's largest standard range of clamping jaws from SCHUNK, the SCHUNK ROTA-M flex 2+2 is equipped with a flexible fine serration (1.5 mm x 60° or 1/16'' x 90°) across all sizes.

www.schunk.com