www.industry-asia-pacific.com

27

'20

Written on Modified on

How does Industry 4.0 impact traditional manufacturing?

Industry 4.0 is a widely discussed topic, with artificial intelligence (AI), big data and machine learning a key element of current developments. But what do these digital activities mean and how will they impact traditional manufacturing?

At Dormer Pramet, we have begun to incorporate Industry 4.0 within our production processes, working with IBM, one of the world’s leading data analysis companies, on several key projects.

This includes using large amounts of data to map the value chain throughout every department of our production unit in Sumperk, Czech Republic, and incorporating computer software to identify defects in tools during the early stages of manufacture.

In the first project, we used advanced algorithms and statistical methods to track every indexable product order from the last two years and how the item moved through the production unit, creating a network model of the entire factory.

This model described how the machines interacted with each other and showed how any process disruptions, such as unscheduled machine downtime, can spread through the entire system. It identified critical points in the process where small issues can cause major inefficiencies later. All were ranked by severity to help focus where improvements were needed to optimize performance and achieve the greatest impact.

In the second phase of the project, we looked at the definition of the metrics that quantified as an issue, such as quality, maintenance downtime or compliance with the production plan. These metrics were again analyzed to identify further areas of operational change and suggest specific improvements.

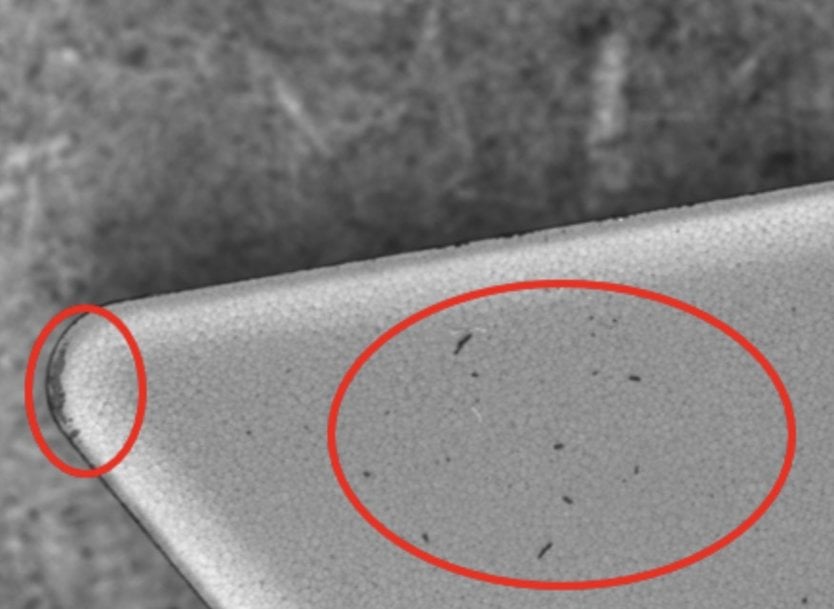

Meanwhile, we are using an IBM inspection station, implemented within a pressing machine, to scan inserts using a series of cameras, lights and moving mechanical elements. This is during the first phase of the production process and can help improve the quality of products at the very beginning of manufacture.

An automatic machine image recognition is performed to locate, as well as identify the type and severity of the defect. This detection uses artificial neural networks – a computerized model which improves performance over-time. Therefore, its success depends on the accuracy of the recognition.

This accuracy is influenced by the number of defect images and their variability which are inputted into the system. By adding as many examples and information as possible will continuously help to teach the

machine what is right and what is wrong on a product.

This not only increases the accuracy of recognition, but helps to detect less obvious defects, reduce false alarms and identify problem characteristics.

All these digital elements and projects aim to enhance our existing high standards of manufacturing capabilities, built on a century of knowledge and expertise. It will allow us to further improve our production processes, increase quality of cutting tools, reduce waste and advance the service provided to customers.

Each of these elements form part of our ‘Make the Shift 2030’ activities which have been established to help create a more sustainable business.

www.dormerpramet.com