www.industry-asia-pacific.com

21

'20

Written on Modified on

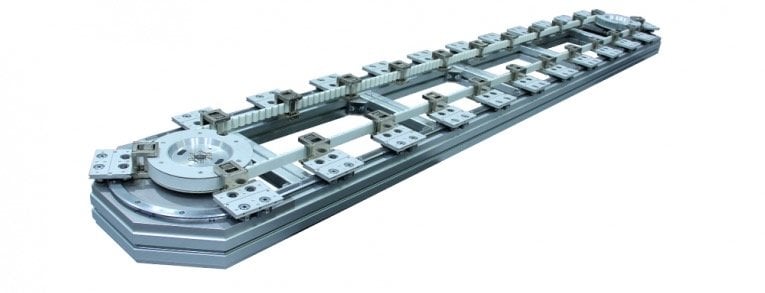

Hepco Launches DTS+ Track System

HepcoMotion is pleased to present the DTS+ track system, the latest addition to the successful Driven Track System range.

Whilst the original DTS will often be the right choice for many applications, the DTS+ is suitable for applications with high loads, a vertical orientation, or where the free space inside the track circuit is required to integrate additional equipment. As with DTS and DTS2, DTS+ comes as a complete package incorporating drive pulleys and belts, together with all the ancillary mechanical parts, limiting design time and ensuring quick installation.

The robust track system was initially developed to meet the needs of Hepco’s Asian market, where DTS+ is established as a go-to product with proven success in the production of leading electronic systems, and has recently been a reliable solution in applications for the production of Covid-19 testing kits in Korea.

DTS+ can handle loadsup to 400N and speeds of up to 1.5m/s when carrying lighter loads. The DTS+ is also available with a carriage locking system which ensures that even with a higher payload and at a greater speed, the superior positional accuracy of +/-0.05mm that features in the DTS system can be maintained.

DTS+ is available in a wide choice of system sizes Including 25-351, 44-468, 44-612 and 76-799 with each system size offering three pulley options. The number of carriages is limited only by their size and the required pocket between carriages on the system.

With its ability to run at considerable speed even in combination with greater loads, and maintaining outstanding positional accuracy, DTS+ will be of great for many applications, particular in assembly, packaging and food production; as well as many other industries.

www.hepcomotion.com